Understanding how to clean ice maker machine is crucial for everyone who owns one, including those who own VEVOR ice maker machines, renowned for their reliability and efficiency. Commercial ice machines, like the VEVOR models, play a significant role in various businesses, serving as vital equipment in restaurants, hotels, and healthcare facilities. Notably, the cleaning ice machine process is not as daunting as it seems. However, it is necessary to learn how to clean these machines efficiently to maintain their functionality and longevity.

Cleaning an ice machine promotes the production of clear, odorless ice, suitable for your customers. Regular ice machine cleaning ensures that your machine runs smoothly, reducing energy consumption and increasing its lifespan. Furthermore, it prevents potential breakdowns that could lead to costly repairs. Therefore, understanding how to clean a commercial ice machine is a great way to ensure that your investment keeps giving back.

Before Cleaning: What Should You Do?

Before embarking on the task of how to clean ice maker machine, it’s vital to ensure all preliminary steps are undertaken for a safe and efficient cleaning process. This groundwork facilitates an effective cleaning process and helps protect both the user and the machine. Here’s what you need to do before you clean your ice maker:

1. Consult the user’s manual: Every ice machine cleaning should start by referencing the manufacturer’s guide. The manual provides specific instructions and precautions that apply to your machine model.

2. Unplug the ice machine: Safety should be your priority. Always ensure the machine is unplugged from the power source to avoid any electrical mishaps.

3. Assemble cleaning supplies: Have your damp cloth, ice machine cleaners and sanitizers, and dish soap ready. Having all necessary items on hand streamlines the cleaning process.

4. Remove all ice and water: The machine should be empty before cleaning. Drain all water and discard any remaining ice to pave the way for a thorough clean-up.

5. Removed Components: If possible, disassemble the parts of the ice machine that can be removed. This ensures you can reach every nook and cranny during cleaning.

By adhering to these steps, you’re sure to have an effective and efficient ice machine clean session.

How to Clean a Commercial Ice Machine: A Step by Step Guide

Cleaning your commercial ice machine is an essential practice that ensures it runs efficiently and produces high-quality ice.

Below, you will find a comprehensive step-by-step guide on how to clean a commercial ice machine:

Step 1: Preparation

Before starting the cleaning and sanitizing process, gather all the necessary supplies. You’ll need ice machine cleaners and sanitizers, a damp cloth, dish soap, warm water, a spray bottle, and a sanitizing solution. It’s crucial to have everything ready before you start to ensure a smooth and efficient cleaning and sanitizing process.

Step 2: Removal of Components

Start your ice machine clean process by carefully removing any removable components of the machine. This step ensures all parts are thoroughly cleaned, even the areas that are usually hard to reach. Note down the order in which you remove the parts to make reassembly easier later on.

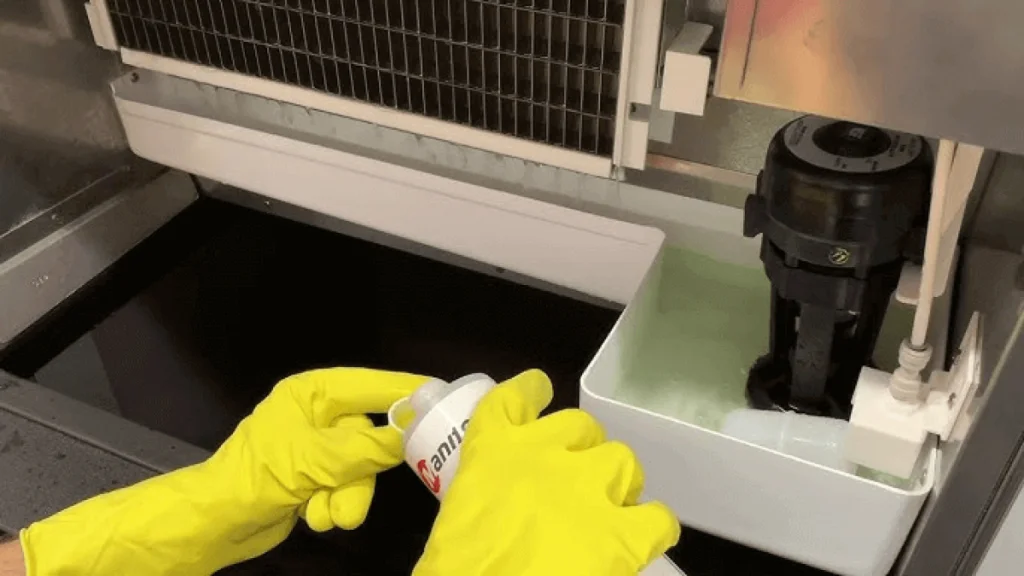

Step 3: Cleaning the Components

Using warm water and dish soap, clean the removed components thoroughly, paying close attention to the nooks and crannies. Afterward, rinse them well to ensure all the soap is gone.

Recommended For Your Project

Step 4: Preparing the Cleaning Solution

Prepare your cleaning solution according to the guidelines given by the manufacturer or using an industry-approved ice machine cleaner. Make sure you adhere to the recommended ratios to prevent potential damage to the machine.

Step 5: Cleaning the Machine

Using your spray bottle, apply the cleaning solution to the interior surfaces of the ice machine. Ensure all areas are covered, including those that are typically hard to reach. Afterward, use a damp cloth to scrub off any visible grime or scale buildup.

Step 6: Running a Cleaning Cycle

Once you’ve manually cleaned the machine, it’s time to run a cleaning cycle. Most commercial ice machines have this feature. The cleaning cycle allows the cleaning solution to circulate through the machine, effectively cleaning the internal components.

Step 7: Preparing and Applying a Sanitizing Solution

After the cleaning cycle, rinse the machine with warm water and prepare a sanitizing solution. Use the spray bottle to apply the sanitizing solution to all interior surfaces of the machine. Sanitizing helps to kill any remaining bacteria or mold, ensuring the machine is safe to use.

Step 8: Running a Sanitizing Cycle

Next, run a sanitizing cycle, if your machine has this feature. If not, simply let the sanitizing solution sit for the recommended time before rinsing.

Step 9: Cleaning the Water Filter

A crucial yet often overlooked step in how to clean ice machine is cleaning the water filter. If your ice maker has a water filter, refer to the user’s manual on how to clean it, or replace it if necessary. A clean water filter ensures your ice is not only clean but also tastes good.

Step 10: Reassembling the Machine

Once all components are cleaned and the interior of the machine is sanitized, it’s time to reassemble. Follow the order in which you removed the components, making sure everything is secure and in its proper place.

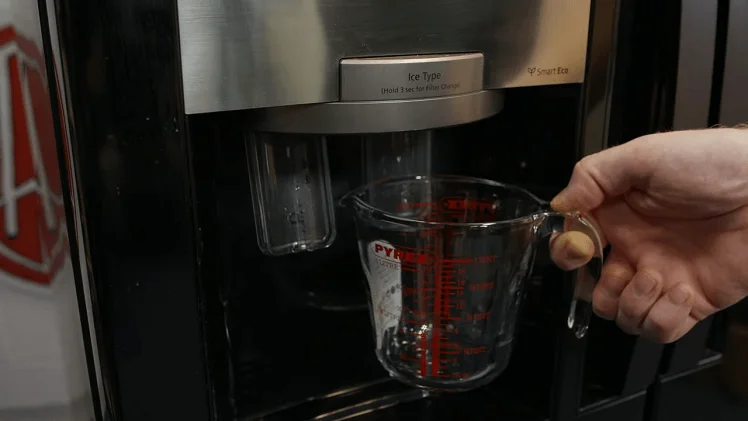

Step 11: Running a Batch of Ice

After reassembly, run a batch of ice to verify if the machine is working properly. Discard this ice as it may still contain remnants of the cleaning and sanitizing solutions. Your commercial ice maker is now ready for regular use.

Throughout the cleaning process, it’s important to ensure the machine is cleaned thoroughly. This includes reaching every corner, ensuring all grime and scale buildup is removed.

will not only extend the lifespan of your commercial ice machine but also maintain the quality of the ice it produces. Regular cleaning also helps prevent costly repairs and replacements down the line.

Step 12: Regular Maintenance

After learning how to clean a commercial ice machine and successfully doing it, you should put a regular cleaning schedule in place. Frequent maintenance keeps your machine running efficiently and increases the overall lifespan.

Step 13: Professional Checks

While regular cleaning is something you can do on your own, it’s also recommended to have a professional perform periodic checks on your machine. This ensures that any hidden issues are identified and addressed before they become bigger problems.

This comprehensive guide should help anyone who needs to clean an ice machine, whether it’s a small unit in a café or a large commercial ice machine in a restaurant. A clean ice machine is a non-negotiable factor in food service operations. It guarantees the health and safety of your customers and upholds the integrity of your establishment.

Signs You Need to Clean Your Ice Maker

Recognizing the signs that indicate your ice maker requires cleaning is critical in maintaining its functionality and efficiency. The following are the signs you should look out for;

1. Cloudy or Soft Ice: If your machine is producing cloudy or soft ice, it could indicate mineral deposits within the machine. Regular ice machine cleaning can eliminate this problem and ensure you get clear, hard ice.

2. Reduced Ice Production: A drop in ice production could mean your machine is overdue for a cleaning. The buildup of scale can decrease efficiency, resulting in less ice.

3. Unusual Noises During Operation: Strange sounds could be a sign of dirt and grime build-up in the machine’s components. Cleaning your machine can help restore its quiet operation.

4. Unpleasant Smell or Taste of Ice: If your ice has a strange smell or taste, it’s time to clean your ice maker. The odor could be a result of mold and mildew.

5. The Ice Machine Takes Longer to Make Ice: When the machine takes longer to produce ice, it may be due to scale buildup, requiring a thorough cleaning process.

Reassembling and Testing the Ice Machine

After successfully cleaning your commercial ice maker, the next step is to reassemble and test the machine to ensure it’s functioning optimally.

Reattaching the Components: Begin by carefully putting back all the removed components. Follow the order of disassembly but in reverse, making sure each part is securely reattached.

Powering the Machine: Plug in the machine and switch it on. Listen for any unusual sounds that could suggest a problem.

Running a Batch of Ice: Lastly, produce a batch of ice to confirm that the machine is working correctly. Discard this initial batch since it may still contain cleaning or sanitizing solution residues.

FAQs About How To Clean An Ice Maker

1. How often should ice machines be cleaned?

Commercial ice machines should ideally be cleaned every 3-6 months, depending on usage and local water quality.

2. How do I maintain a commercial ice machine?

Aside from regular cleaning, it’s crucial to replace the water filter every six months and schedule regular professional checks for optimal performance.

3. How do I know if my ice machine needs cleaning?

Signs that your ice machine requires cleaning include cloudy or soft ice, reduced ice production, unusual operation noises, or an unpleasant smell or taste from the ice.

Conclusion

In conclusion, understanding how to clean an ice maker is vital for any business owner or individual who uses these machines. Regular ice machine cleaning not only improves the quality of the ice produced but also extends the lifespan of the machine, preventing costly repairs and replacements. The process of cleaning an ice machine involves several steps, from the removal and cleaning of components, through to reassembling and testing the machine.

Implementing regular cleaning schedules and conducting professional checks adds to the overall efficiency of your commercial ice machine. Clean ice machines mean cleaner, better-tasting ice, contributing to satisfied customers and successful businesses.