The Heavy-duty three-jaw puller is used to remove automotive gears and bearings. They have three arms that help securely grip the parts and pull them off the spindle. They are widely used for heavy-duty machinery. VEVOR heavy-duty three-jaw pullers are easy to use and work without being worried about any kind of damage done. They are of high strength and can be used for a long time. This guide will help you in buying the best heavy-duty three-jaw pullers.

Top 5 Heavy Duty 3 Jaw Puller

There are different types of Heavy-duty three-jaw pullers available, but here in this guide, we will discuss the top 5 VEVOR heavy-duty three jaw puller, which is as follow:

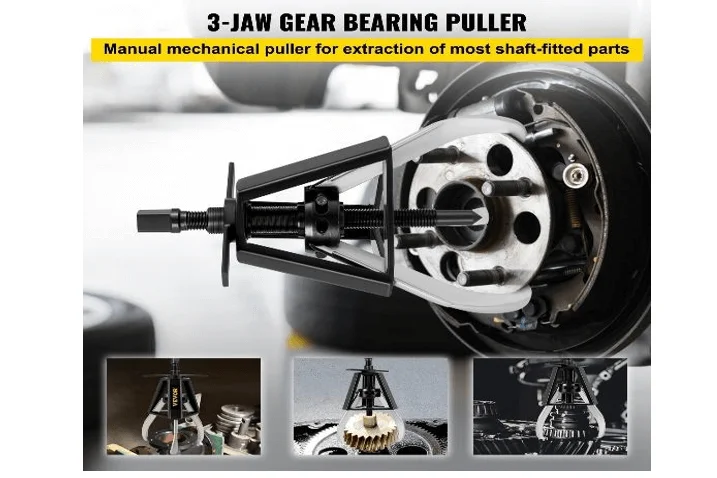

1- 3 Gear Jaw Puller

Features and Performances

Damage-free:

The heavy-duty 3-jaw puller is the best to use as it works without causing any damage. With the help of this jaw puller, you can take out the shaft-fitted parts, which include gears, bearings, pulleys, etc.

Puller tool:

It has a 20-ton puller tool.

Speed Range:

The speed range of this heavy-duty 3-jaw puller is 4.9″ to 12″.

Speed Reach:

The speed range of this heavy-duty 3-jaw puller is 19″ to 24.5″.

Crafted Claws:

The crafted claws prevent slipping and make the grip firm.

Steel Jaws:

This heavy-duty 3-jaw puller has tapered steel jaws which securely clamped. The tapered steel jaws concentrically pulled. It has the same load distribution. It can easily enter narrow spaces with the help of slim tie rods and center bolts.

High pulling strength:

The heavy-duty 3-jaw puller has high strength and can easily pull.

Installation:

Unlike other pullers, VEVOR products do not any installation. You can use it directly.

Material used:

The jaws are made of forged hardened steel. The center screw is coated with a black oxide layer.

Pros:

● Corrosion resistant.

● Good choice for Car maintenance factories, mechanical factories, repair workshops, etc.

2- Hydraulic Gear Puller

Features and Performance:

Material Used:

Heavy-duty forged steel is used in the making of Hydraulic Gear Pullers. The material used in the making makes it durable, as there is also no oil leakage.

Capacity:

Its capacity is 33069 lbs (15T ) which makes it useful for long service time.

Adjustable jaws:

You can adjust the jaws according to your required height. The use of a hydraulic gear puller is very easy as the pump head can easily be rotated to 360 degrees which makes it easy to operate.

Bidirectional Operation:

You can operate the hydraulic gear puller horizontally as well as vertically without site restriction. It has a 2″ (50 mm) axis travel with a 7″ (180 mm) max reach and 12″ (300 mm) max spread.

Equipment:

It is equipped with:

● Safety relief valve

● Piston Rod

● The Detachable Ejector Pin

● The Movable Handle.

Load Distribution:

The hydraulic gear puller has load distribution; it event distributes the tension, which helps you to securely clamp and concentrically pull.

Pros:

● Ideal for pulling hubs, flanges, gears, pulleys, flywheels, bearings chucks from shafts.

● Suitable for car maintenance factories, mechanical factories, and repair workshops.

3- 1 Ton/2204 LBS Capacity Manual Puller

Features and Performance:

Damage-free removal:

This gear puller is your best partner in terms of taking out shaft-lifted parts like gears, bearings, and pulleys. You can take out the parts that are required without worrying about any damage.

Spread Reach and Spread Range:

The spread reach of this gear is 13″ to 21.6,” and the spread range is 3.9″ to 7.9″.

Crafted Claws:

The crafted claws of this gear puller are firm. You do not have to worry about slipping while working. The secure grip of the gear will prevent any kind of slipping.

Strong Jaws:

The three-jaw structure of this gear puller is strong as it is made of steel. These jaws have the same load distribution. The slim tie and the center bolts can easily enter small and narrow spaces.

Strength:

This gear puller has high strength. It is corrosion-resistant because of the coated black oxide layer on the center screw.

Installation:

The three jaws of this gear puller are made of forged hardened steel and do not need to be installed. You can directly use it.

Pros:

● Perfect for use if you need to remove gears, pulleys, bearings, and flywheels.

● Perfect for maintenance factories.

4- VEVOR 3 Gear Jaw Puller

Features and Performance:

Material Used:

The material used in making VEVOR 3 Gear Jaw Puller is forged hardened steel, which makes it strong and durable.

Strength:

The three-jaw structure of this gear jaw puller is strong as it has the same load distribution clamping and pulling. There is less manual labor as most of the part is done by the 3-gear jaw puller.

Use:

The main use of the 3 Gear jaw puller is to take out the shaft-fitted parts like gears, bearing, and pulleys.

They have a spread reach from 13″ to 21.6,” and the speed range is 3.9″ to 7.9″.

Puller tool:

It is a 5-Ton puller too.

Steel Jaws:

They have high-strength steel jaws and can be directly used as they do not require any installation.

Pros:

● Corrosion resistant.

● Already installed.

● Slim ties and center bolts can easily reach narrow spaces.

5- 10 Ton/22040 LBS Capacity Manual Puller

Features and Performance

Strength:

This manual gear puller has enough strength to take out the shaft-fitted parts such as gears, bearings, pulleys, etc.

Spread Reach:

The spread of this gear puller is 11″ to 16.3″.

Spread Range:

The spread range of this gear puller is 4.4″ to 9.8″.

Steel Jaws:

This gear has steel jaws that have the same load distribution. The center crew is coated with the black oxide layer with corrosion resistance.

Pros:

● Best in removing gears, pulleys, bearings, and flywheels.

● Steel jaws can be griped and removed easily.

Different types of Heavy Duty Jaw Puller

There are different types of heavy-duty puller, some of which are discussed in this article, and these are as follow:

Two Jaw pullers:

Two jaw pullers are the most common type of puller. They are widely used. They are used to take out the shaft-fitted parts and especially where the access of other pullers is limited.

Three-jaw puller:

Three jaw puller is also widely used. They are used in mechanical industries, factories, and shops.

Mechanical Pullers:

These pullers work by rotating a crossbar. The crossbar moves the center screw towards the shaft. These pullers are mechanical and save manual labor.

Hydraulic Pullers

A hydraulic cylinder in the hydraulic pullers is powered by a pump. There are many tools designed for hydraulic pullers to remove bearings, that Enerpac offers bearing pullers, bearing separators, and bearing cup pullers.

Internal and External pullers:

There is internal and external puller when it comes to bearing pullers. The internal puller is used where the bearing is fitted within a recess, and the external puller is used when the bearing is mounted onto the shaft.

Every bearing puller falls into the broad categories of either an external bearing puller or an internal bearing puller.

What should you look for when buying a Heavy Duty 3 Jaw Puller?

When you are looking for a heavy-duty 3-jaw puller, your decision is dependent on many factors. You need to keep in mind a few things to make the decision easy. These points are as follows:

Requirement:

First of all, you need to know whether you need an internal jaw puller or an external jaw puller.

● If you need to remove the recess within the inner diameter, then you need an internal bear puller.

● If you need to remove seated on a shaft accessible for outer diameter, then you need an external diameter.

Budget:

If you have enough budget, then you can buy any according to your requirement, but if the budget is low, a mechanical bearing puller may be suitable.

Material used:

Look for the material used in the making of the heavy-duty three-jaw puller.

Space Condition:

You need to consider the space condition, which includes the diameter and depth of the bearing. You also need to the space around the bearing as some bearing pullers require more space.

Manual effort labor:

If you want to reduce the manual effort, hydraulically-assisted bearing pullers are suggested because they are best used for heavy-duty machinery.

Take expert suggestions:

If you don’t know enough about heavy-duty three-jaw pullers, you can take the suggestions from the experts so that it won’t be a waste of money and time.

Is Heavy-duty 3 Jaw Puller Worth It?

There are different kinds of heavy-duty jaw pullers available in the market. You can easily buy any according to your requirement. VEVOR heavy-duty three-jaw puller is a must-buy as they are one of the most used jaw pullers and are efficient in working.

FAQ Heavy duty 3 Jaw Puller

Q: How deep can the bearing reach?

A: This depends on what your structure is.

Q: Are they durable?

A: Yes, they are durable.

Q: Are heavy-duty three-jaw pullers strong?

A: Yes, the heavy-duty three-jaw pullers use steel, making them strong and durable.