You’re planning to transport a heavy load on your flatbed truck, but you need to figure out what straps to use or how to secure your load properly.

Having the correct type of straps or adequately securing your load can lead to dangerous and costly accidents on the road. Imagine your load shifting or falling off your truck, causing damage to other vehicles or, even worse, injury to yourself or others.

Learn about the different types of straps available, such as flatbed straps, ratchet straps, and cam buckle straps, and how to use them to secure your load correctly. Ensure you follow the best practices for load securement to ensure safe and successful transport.

With the proper knowledge and equipment, you can be confident that your load will be safely and securely transported. Don’t take unnecessary risks on the road. Take the time to educate yourself on straps and ensure your load is secured correctly.

The Importance of Flatbed Straps in the Transportation Industry

Transportation is a vital part of the modern world, and the transportation industry plays a crucial role in keeping the economy moving. Whether moving goods across the country or transporting heavy equipment, the safety and security of the cargo are of the utmost importance. The flatbed strap is one essential tool for ensuring cargo’s safe and secure transport.

Flatbed straps are designed to secure heavy loads on trucks and trailers, ensuring they remain in place during transit. These straps are made from durable materials and are designed to withstand the rigors of transport, including harsh weather conditions and rough road conditions. They come in various sizes and designs, making them suitable for a wide range of cargo.

Top 5 Popular Brand of Flatbed Straps

Flatbed straps are essential for securing and transporting heavy loads on a flatbed truck. They come in various sizes, strengths, and materials to meet different needs. With so many options available, it can be overwhelming to choose the right one.

To help you out, we’ve rounded up the top 5 most popular brands of flatbed straps.

VEVOR Flatbed Straps

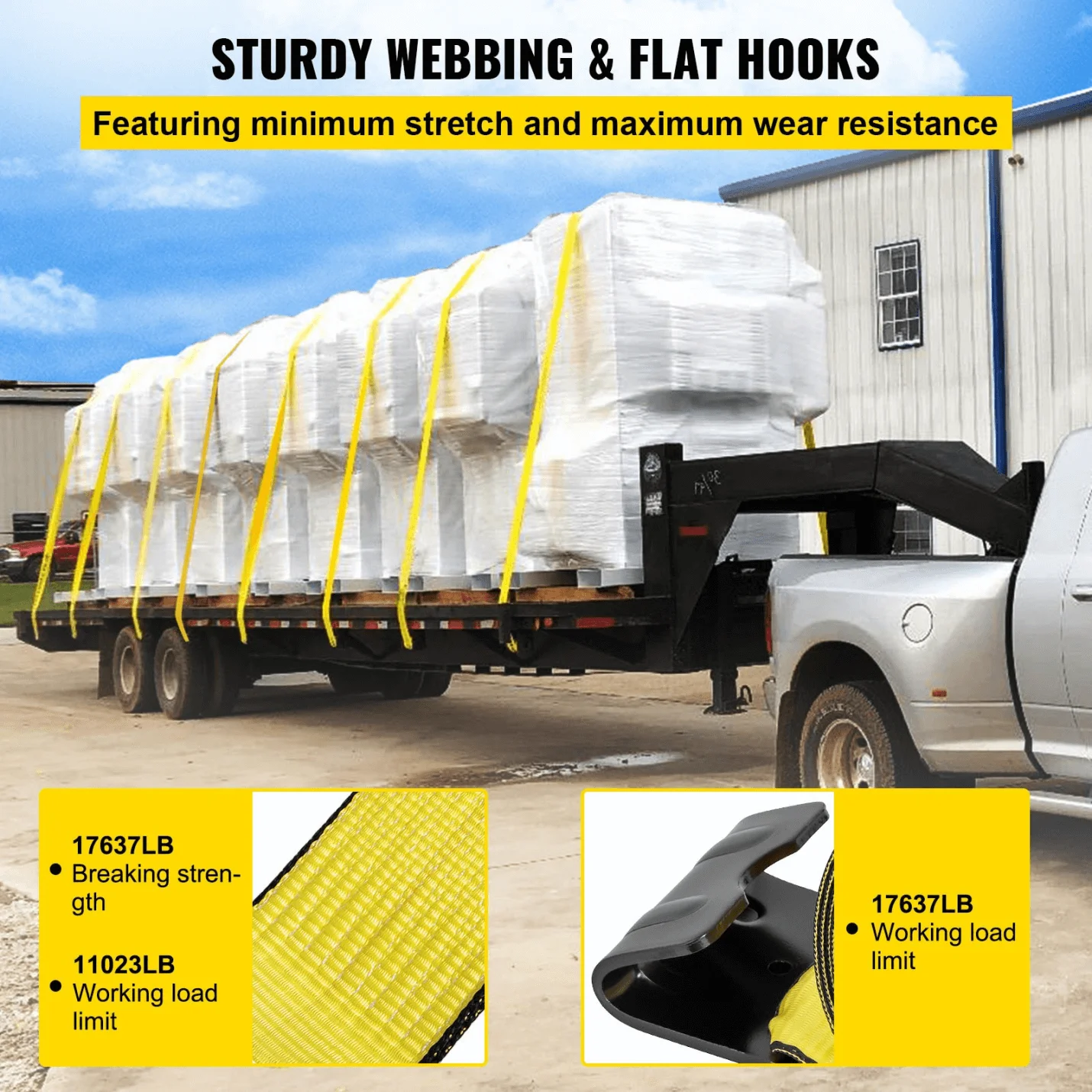

Flatbed Tie Down Strap 4″ x 40′ Winch Straps w/ Flat Hook: These flatbed straps from VEVOR are the ultimate solution for securing heavy loads. The semi-truck straps are made of durable fabric and metal. Their assembly break strength can reach 17637 pounds, and the working load limit is 11023 pounds.

They feature flat hooks at both ends, making them easy to attach to your flatbed truck or trailer. These straps are UV-resistant, ensuring they will withstand harsh weather conditions. Since you are interested in this product, you might also want to check VEVOR’s rolling shop stools, diesel heater for van, electric stainless steel meat grinder, and ice melt mats.

Ratchet-Pro

Known for its high-quality, heavy-duty ratchet straps, Ratchet-Pro is a top choice for those who need to transport large and heavy loads. Their straps are made of industrial-grade webbing and feature a patented ratchet design for maximum tension and holding power.

Keeper

This brand is known for its versatile and durable flatbed straps. Their straps are made of strong webbing and feature a patented “S” hook design that prevents accidental release. They also have a wide range of sizes and styles to choose from.

Secure-It

Secure-It is a trusted name in the flatbed strap industry, known for its innovative and reliable products. Their straps are made of heavy-duty webbing and feature a double J-hook design for added security. They also offer a wide range of sizes and styles to suit different needs.

Erickson

Erickson is a leading flatbed strap market brand known for its high-quality and durable straps. Their straps are made of heavy-duty webbing and feature a patented ratchet design for added strength. They also offer a wide range of sizes and styles to suit different needs.

Types of Flatbed Straps

When hauling cargo on a flatbed truck, it’s essential to have the correct type of flatbed straps to ensure that your load stays secure and doesn’t shift during transport. There are several different types of flatbed straps available on the market, each with its unique features and benefits. Here are some:

Chain binders

Chain binders are a heavy-duty option for securing large or heavy loads. They are made of steel, making them highly durable, and can be adjusted to fit a wide range of cargo. They are also great for loads that are difficult to tie down with other straps.

CAM Buckle Straps

These straps feature a cam buckle that allows you to adjust the tension on the strap, making it easy to secure your load. They are also lightweight and easy to transport, making them an excellent option for on-the-go tie-downs.

Ratchet Straps

Ratchet straps are a versatile option for securing a wide range of cargo. They feature a ratcheting mechanism that allows you to adjust the tension on the strap, making them perfect for loads that require a tighter hold. They are also made from durable materials designed to withstand harsh weather conditions.

Axle Straps

Axle straps are designed to secure cargo by wrapping around the axles of your flatbed truck or trailer. They are great for loads unsuited for traditional tie-down straps, such as heavy machinery or vehicles. They are also made from durable materials and feature a ratcheting mechanism for easy tension adjustment.

Proper Use of Flatbed Straps

Whether you’re a truck driver, a warehouse manager, or a business owner, understanding the proper use of flatbed straps is vital for ensuring the safety of your cargo, equipment, and drivers. So, let’s buckle up and get ready to learn how to use flatbed straps for smooth and safe transport properly.

1. Choose the Right Flatbed Straps for the Job

The first step in properly using flatbed straps is to ensure that you have the proper straps for the specific load being transported. It’s essential to use straps rated for the weight of the load and appropriate for the shape and size of the load. This can help to ensure the load stays securely fastened to the flatbed during transport.

2. Position and Tension the Straps Correctly

Once you’ve chosen the suitable straps for the job, the next step is to position and tension the straps correctly. Pay attention to the load’s center of gravity and ensure that the straps are positioned to keep the load balanced and stable.

3. Inspect and Maintain Your Straps Regularly

Regular inspection and maintenance of flatbed straps are essential to ensure they are in good condition and ready to use. This includes checking for wear and tear, fraying, or other damage that could compromise the integrity of the straps.

4. Follow Safety Guidelines

When using flatbed straps, following all safety guidelines and regulations is essential. This includes ensuring the straps are correctly positioned and tensioned, and the load is correctly secured to the flatbed. It is also essential to use the proper PPE, such as gloves, safety glasses, and hard hats, when handling the straps to minimize the risk of injury.

5. Check the load during transport

Finally, checking the load during transport is essential to ensure that the straps are still secure and that the load hasn’t shifted. This can help to prevent accidents and damage to the load. If any issues are noticed, address them immediately and make any necessary adjustments to the straps or the load itself.

What Should You Look for When Buying a Flatbed Straps

When buying flatbed straps, there are several key factors to consider to ensure the safety and security of your load and the operator. Here are a few:

1. First, it’s essential to consider the strength and durability of the straps. Look for straps made from high-strength materials like polyester or nylon, and check for certifications like those from the WSTDA (Web Sling & Tie Down Association) or the American Society for Testing and Materials (ASTM).

2. Next, think about the specific needs of your load and the type of flatbed you’ll be using. Will you be transporting heavy machinery or oversized cargo? Look for straps with wide, reinforced webbing to distribute the load evenly and prevent damage. Will you be traveling over rough terrain or through inclement weather? Look for straps with weather-resistant coatings to prevent wear and tear.

3. It’s also essential to consider the potential dangers of misusing flatbed straps. Improperly securing a load can lead to accidents on the road, damage to the cargo, and even injury or death to the operator or other drivers. To ensure safety, follow the manufacturer’s guidelines for properly using and maintaining the straps and conduct regular inspections to check for wear and tear.

5. Finally, knowing the legal and regulatory requirements for using flatbed straps is essential. The Federal Motor Carrier Safety Administration (FMCSA) and the Department of Transportation (DOT) have strict guidelines for securing loads on commercial vehicles, including flatbeds. Make sure to comply with these regulations to avoid fines and penalties.

Are Flatbed Straps Worth It?

Flatbed straps are essential for anyone who regularly transports cargo on a flatbed truck. These straps are designed to secure and stabilize your load, preventing it from shifting or falling off during transport. But are they worth the investment? The answer is a resounding yes.

First and foremost, flatbed straps provide an added level of safety for both you and other drivers on the road. Keeping your load secure reduces the risk of accidents or damage to your cargo. This not only keeps you protected but also helps to protect other drivers and their vehicles.

Also, flatbed straps are incredibly versatile and can secure various loads. From heavy machinery to fragile cargo, flatbed straps can accommodate it all. This means you can use them for multiple types of deliveries, making them a cost-effective option in the long run.

Another benefit of flatbed straps is that they are durable and long-lasting. They are made to withstand the elements and the wear and tear of regular use, so you won’t have to worry about constantly replacing them. You can save money on replacements and maintenance costs in the long run.

Conclusion

In conclusion, flatbed straps are an essential tool for any transportation business. Not only do they provide a secure hold for your cargo, but they also ensure the safety of your employees and other drivers on the road. High-quality straps are a worthwhile investment, as they are durable and long-lasting.

However, it is essential to use them properly to ensure that your cargo is transported safely and securely. Pay attention to quality when it comes to flatbed straps, as they are a crucial part of your transportation operation. Invest in the best and use them correctly to ensure your cargo reaches its destination safely.

FAQ About Flatbed Straps

1. What are flatbed straps, and how do they work?

Flatbed straps are heavy-duty straps used to secure cargo on flatbed trailers. They are typically made of durable materials such as polyester or nylon and are equipped with ratchets or other tensioning devices to keep the cargo tightly in place. Flatbed straps wrap around the cargo and then tighten it to hold it securely. This ensures that the cargo will not shift or fall off during transportation.

2. How do I choose suitable flatbed straps for my cargo?

When choosing flatbed straps, it is essential to consider the size and weight of your cargo. You will want to select straps that are strong enough to hold your cargo in place but not so tight that they damage or deform the cargo. Additionally, you should consider the type of cargo you will be transporting, as some straps may be better suited for certain types of materials.

3. How do I properly use and maintain flatbed straps?

To properly use flatbed straps, you should always follow the manufacturer’s instructions for proper installation and tensioning. This will ensure that the straps are used correctly and that your cargo is secured safely. Additionally, you should regularly inspect your straps for signs of wear or damage and replace them as necessary. Proper maintenance, such as cleaning and storing straps properly, will also help prolong their lifespan.