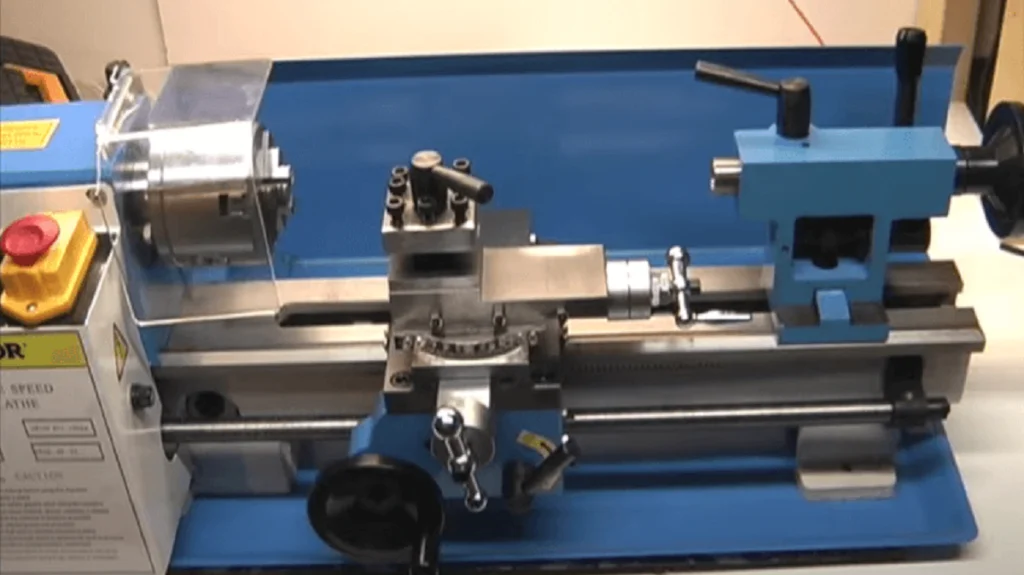

Metal lathes are indispensable tools in machining, shaping raw materials into precision components. In a first look, lathes are odd tools. The entire machine is oriented side by side, and the workpiece is in a horizontal position. Also, a crucial thing to note here is that the tool itself doesn’t spin.

Instead, the workpiece rotates, and the tools will slide side to side along the bed’s length. Simply put metal lathes neither look nor do they function as the regular drill. Therefore, it can be challenging for a beginner to use them. Nevertheless, this article will help you with using a metal lathe.

We’ll tell you about how to operate a metal lathe safely. This article will give you a comprehensive idea about the core components of this tool and how you can use it safely. You will ensure that you can safely use the VEVOR metal lathe. Let’s start by understanding the basics of metal lathes.

Table of contents

Understanding the Basics of Metal Lathes

A lathe is a useful tool that can help you work with wood or metal. The metal lathe turning process is quite different from the standard drill or mill. The cutting bit will not spin, rather it will move into the rotating workpiece. Compared to a drill or a mill, the workpiece is still, and the cutting bit rotates.

But that is not the case with the metal lathe. Furthermore, there are three basic types of metal lathes:

- Turret Lathe – It is common in industrialized manufacturing processes. This lathe incorporates a multiple-headed turret so that it can hold more than one cutting bit.

- Special Purpose Lathe – This type of lathe is usually on the assembly lines where they will create customized parts as a core element of a specific process.

- Engine Lathe – The engine lathe has everything including a moveable head, tailstock, headstock, etc. The workpiece will be in between the headstock and the tailstock, where the former will move and engage in the cutting part.

So, there you have a brief idea about what is the lathe machine. But there are other things that you need to keep in mind as a beginner. Let’s move on to the critical components of a robust metal lathe for your projects.

Metal Lathe Cutting Tools: A Closer Look

Before we move on and learn how to use a metal lathe, finding out the importance of selecting the right cutting tools is vital. Since a metal lathe is a versatile machine, you can equip it with a wide range of instruments according to your project needs. Here are a few types of metal lathe-cutting tools.

Boring Bars

The boring bars help in widening the existing holes for pieces that are on the lathe. This tool will pierce into the wood or metal, which will give you plunge cuts that you can thread or smooth out.

External Turning

External turning tools play a major role in removing the most amount of material quickly. You can also find rougher versions of these tools to shape the piece according to your convenience. Once this process is complete, the finishing tool will bring out the polished surface.

Threading

One of the biggest categories of the various kinds of lathe tools is threading. You can find a wide range of thread cuts, such as:

- Square

- Small

- Large

As a metal lathe beginner, you can use the threading tools for internal threads, such as a nut, or external threads like the ones on the screws or bolts.

Operating Your Metal Lathe: A Step-by-Step Guide

So, how to use a metal lathe as a beginner? While no rocket science goes behind in the process, you need to be careful when operating this machine. To make things easy for beginners, here is a step-by-step guide for operating a metal lathe.

Step 1: Powering Up Your Metal Lathe

First, users must familiarize themselves with the control panel functions. They should know how to operate the lathe machine before they start working on it. VEVOR’s metal lathes come equipped with user-friendly control panels, making the initialization process intuitive for beginners.

Step 2: Material Preparation

Next up, you need to select the right metal for a project is crucial. Different metals have varying properties, affecting how they respond to cutting and shaping. Beginners should consider factors, such as hardness, machinability, and thermal conductivity when choosing materials.

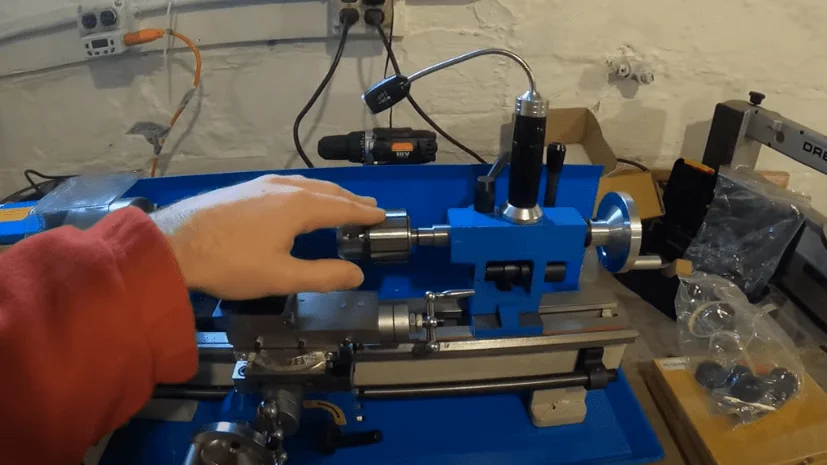

Step 3: Tool Setup and Selection

After preparing the material, the next step entails choosing the appropriate cutting tools. Consider the project requirements to find which tools you need for turning, facing, and threading. Also, make sure to properly install and adjust tools in the tool for maximum accuracy and efficiency during machining.

Step 4: Setting the Speed and Feed Rates

Beginners should refer to the lathe’s specifications and guidelines for recommended speed and feed rates based on the selected material. With VEVOR’s metal lathes, users have flexibility in their machining processes because of the adjustable speed settings.

Step 5: The Art of Facing and Turning

Facing involves creating smooth surfaces on the workpiece while turning is the process of shaping and molding the metal. Beginners should follow detailed guidance on these processes to achieve the desired outcomes:

- Understanding the nuances of tool positioning

- Depth of cut

- Feed rates

Step 6: Threading Mastery

If your project entails threading operations, then it adds a layer of complexity to metalworking. Since there are different varieties of thread cuts available, you can choose the one that is suitable according to your project. This is an important part that you need to know about for using metal lathe for beginners.

Step 7: Cleaning Up and Shutting Down

Completing a metalworking project involves more than just shaping the material. As a beginner, you need to also pay attention to the finishing touches.

Start by removing burrs and imperfections from the machined surfaces. Also, make sure to properly shut down the metal lathe according to the manufacturer’s guidelines. It will ensure the machine is ready for future use.

Safety Measures & Common Mistakes to Avoid for Beginners

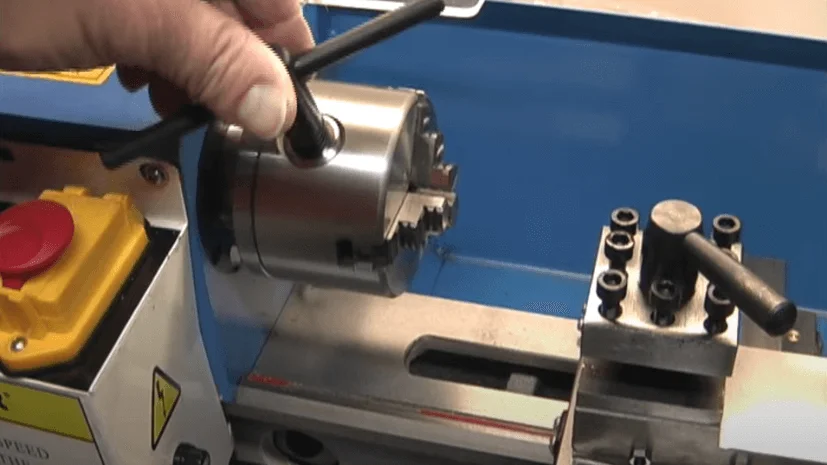

The most critical element when it comes to how to operate a lathe is the safety measures that beginners need to take. You need proper personal protective equipment that includes wear eye and ear protection.

Plus, staying vigilant is also essential for any flying chips and fragments when operating the machine. Also, roll sleeves above elbows and make sure to remove any accessories, such as rings and watches. In addition to that, here are some tips to help in usage of lathe for beginners:

- Turn off the lathe before you make any adjustments

- Make sure that the lathe comes to a complete stop before changing any spindle speeds

- Don’t try to measure work during the turning process

- Before operating the machine, remove chuck keys and wrenches

- Be cautious when dealing with sharp cutters, centers, and drills

Choosing the right metal lathe is also very important. So, when you select one, make sure to get a metal lathe machine that has multiple security features in case of emergency. The emergency stop will ensure that the machine is stopped and keep you and others safe from any possible mishap.

Troubleshooting Tips for Common Issues with Metal Lathes

Operating a metal lathe can be a rewarding experience, but like any machinery, it may encounter issues from time to time. Here are some troubleshooting tips to help you navigate common problems and ensure smooth metalworking operations:

Issue – Uneven Cuts or Rough Finishes

This could be probably because you didn’t secure the workpiece properly or the cutting tools are dull.

Troubleshoot: Ensure the workpiece is securely fastened in the lathe chuck. You can sharpen or replace dull cutting tools to maintain precision.

Issue – Excessive Vibration

This could be due to a misalignment of components or an unbalanced workpiece.

Troubleshooting: Check for any misalignment in the lathe components and correct them as needed. Also, make sure that the workpiece is balanced before starting the lathe.

Issue – Overheating of Cutting Tools

Inadequate cutting fluid or incorrect cutting speed.

Troubleshooting: Use an appropriate cutting fluid to lubricate and cool the cutting tools. Adjust the cutting speed to match the material and tool specifications.

Exploring Advanced Techniques

If you want to learn the lathe basics in a much better way, then you should try to gain hands-on experience. It means working with someone who has experience in handling the lathe machine. Take up apprenticeship programs in your area to grasp the skills and become a skilled user of the lathe machine.

Additionally, you can check out online resources to get information about advanced techniques like CNC machining. Nevertheless, it is important that you start with the basics and then move towards the advanced level — that too under proper supervision.

Summing up

We hope you have a clear idea about how to run a lathe as a beginner. It ensures that you know about the safety measures to take before using the machine. Also, with the step-by-step guide, you can know the safe method to start and use the machine.