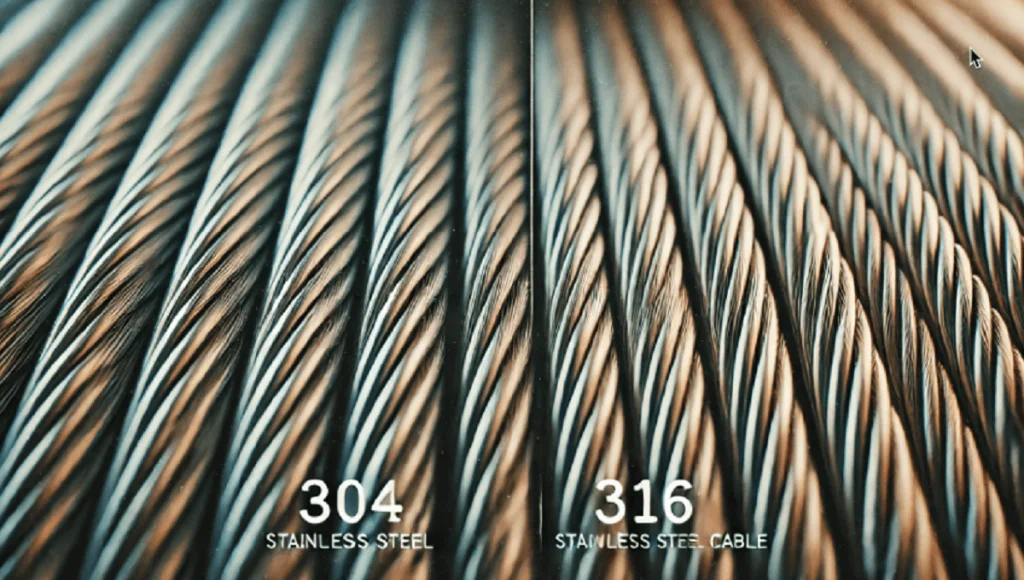

If you need stainless steel for any type of project, particularly stainless steel cable, then knowing what the differences between various types of stainless steel are is very crucial. For instance, two of the most common types of stainless steel include 304 and 316 stainless steel.

These are two different grades of stainless steel, both of which are commonly used in a wide variety of industries and applications. With that being said, 304 and 316 stainless steel have certain differences between them that you absolutely need to know about, and that’s exactly what you’re here to discuss today.

Something to keep in mind however is that VEVOR, a leading manufacturer of such products, offers both 316 and 304 stainless steel cables to suit a wide variety of needs. This in-depth guide will provide you with all the information you need to choose between 304 and 316 stainless steel.

Table of contents

What is Stainless Steel?

To provide you with a bit of an introduction, stainless steel is actually an alloy. It is made primarily out of nickel, chromium, iron, and carbon. The combination of materials used to create this type of stainless steel makes it very durable, strong, and resistant to corrosion.

Most types of stainless steel have at least 10.5% chromium, this helps form a layer of chromium oxide on the outermost surface of the stainless steel. This also helps prevent the stainless steel from tarnishing and rusting.

There are other elements, such as molybdenum and nitrogen, which can be added to stainless steel configurations to help enhance various properties. These properties may include resistance to chemicals, temperature resistance, malleability, formability, and strength.

What Are Stainless Steel Cables?

We then have stainless steel cables. These may also be referred to as a wire rope. These consist of many different strands of stainless steel wire that are twisted together to form a single flexible, strong, and corrosion-resistant type of rope or cable.

There are many different configurations that can be used, with different amounts of wires and strands, resulting in different properties. For instance, there are types of stainless steel cables that feature a 1X19 construction, which means that it is made out of a single strand that is made of 19 wires. This is extremely strong but not overly flexible.

On the other hand, you can have something like a 7X19 construction, which means that the stainless steel cable in question is made out of seven strands, each of which contains 19 wires. This forms a very flexible type of stainless steel cable, although it can’t hold as much weight as other configurations.

Similarities Between 304 vs 316 Stainless Steel

There are some similarities between 304 and 316 stainless steel that are worth noting. Yes, we are here today to talk more about the differences, but some similarities need to be talked about.

Strength

One of the biggest similarities shared by both of these types of stainless steel is that they are both known for being extremely durable. More than anything else, they have high tensile strength, which means that they can handle a lot of weight. If you need a long-lasting material that is strong and durable, then both 304 and 316 stainless steel are ideal.

Resistance to Corrosion

One of the biggest benefits of stainless steel in general, whether we are talking about 304 or 316 stainless steel, is that both have excellent rust and corrosion resistance. This makes both types of stainless steel suitable for a wide variety of environments. With that being said, both do have slightly different compositions, something we’ll take a closer look at further below.

Versatile Uses

Yet another similarity shared by both 304 and 316 stainless steel is that they are quite versatile. They can be used in many different industries and applications. This can include marine environments, industrial settings, kitchen equipment, chemical containers, architecture construction, and so much more. VEVOR stainless steel cables work for all of these applications and more.

Easy to make

The other similarity shared by 316 and 304 stainless steel is that they are very easy to make, form, and Weld. They are very easy to work with, which makes them popular for a variety of construction and manufacturing purposes.

Differences Between 304 vs 316 Stainless Steel

Although there are a great deal of similarities between 304 and 306 stainless steel, there are even more differences between them. What we want to do today is to take a closer look at the main differences between 304 and 316 stainless steel, particularly in terms of their properties and chemical composition. Although there are differences between them, remember that VEVOR offers both 316 and 304 stainless steel products to suit your needs.

The Composition

First and foremost, the chemical composition of 304 stainless steel and 316 stainless steel are different, and this leads to all of the other differences that we’ll take a closer look at further below.

If we are talking about 304 stainless steel, this usually contains 8% nickel and 18% chromium. This allows for great formability and corrosion resistance.

However, we then have 316 stainless steel. This contains 16% chromium, 10% nickel, and 2% molybdenum. The higher molybdenum content helps to enhance crevice corrosion and pitting resistance. This is important in environments that contain a lot of chloride and salt.

Resistance to Rusting and Corrosion

As mentioned above, the chemical composition of these two types of stainless steel is different, and the next biggest difference this leads to is corrosion resistance.

If we are talking about 304 stainless steel, this has great corrosion resistance in most cases. However, it is susceptible to crevice corrosion and pitting, especially in settings such as coastal areas, marine environments, and chemical plants. This is also especially the case in settings that contain a lot of chloride.

In terms of 316 stainless steel, this has much better corrosion resistance. This is especially the case with industrial solvents and chlorides, but also against salt. 316 stainless steel is therefore the better choice for chemical processing and marine applications.

Recommended For Your Project

Overall Durability and Strength

In general, 304 stainless steel is durable and has great tensile strength. However, 316 stainless steel has even more tensile strength. It also performs better in harsh environments. When it comes down to it, 316 stainless steel is simply the better type for harsh environments and for conditions where heavy loads need to be well-supported.

Price

As is often the case, you get what you pay for, 304 stainless steel is more cost-effective than 316 stainless steel. This is generally due to the complete absence of molybdenum as well as the lower nickel content.

If you are working on a budget, then 304 stainless steel is more than ideal. However, if you need something higher quality, we recommend investing a little more money into the higher quality 316 stainless steel. It’s a bit more expensive because it has better properties.

Uses of 304 Stainless Steel

304 stainless steel is cost-effective and quite versatile, which is why it is often used in a wide variety of applications. It has a great balance of corrosion resistance, formability, and strength. Some of the most common applications of 304 stainless steel include the following.

- 304 stainless steel is frequently used in the manufacturing of many different types of kitchen equipment. This can include cookware, countertops, and kitchen sinks. It’s great for kitchen use because it can withstand high temperatures while also resisting corrosion.

- 304 stainless steel is often used for the creation of containers, tanks, and machinery for the food processing industry. It is able to resist food acid and cleaning chemical corrosion, making it a great hygienic choice for any kind of surface that comes into contact with food.

- This type of stainless steel is often used in the automobile industry to create components such as trim and exhaust systems. It’s very resistant to rusting and durable as well, therefore ensuring great performance over a long period of time in vehicles.

- When it comes to architectural applications, 304 stainless steel is also quite popular. It can be used for a wide variety of decorative elements, handrails, and exterior cladding. It’s very resistant to weather and also has great aesthetic appeal.

Uses of 316 Stainless Steel

Due to its higher strength and corrosion resistance, you can expect 316 stainless steel to be used in more professional and industrial types of applications.

- 316 stainless steel is often used for marine applications and coastal environments, mainly because it has much better resistance to corrosion from salt water than 304 stainless steel. It’s used for making a variety of marine hardware, rigging, and boat fittings.

- 316 stainless steel is also one of the most popular options to use in a variety of chemical processing industries. It’s often used to make valves, pipes, and tanks. It has high resistance to aggressive solvents and chemicals, therefore making it a reliable and safe option in chemical processing environments.

- 316 stainless steel has great biocompatibility, strength, and corrosion resistance. This makes 316 stainless steel an ideal option for creating a variety of medical implants and surgical instruments that require great performance and hygiene. On that note, the pharmaceutical industry uses 316 stainless steel to make a variety of storage tanks, mixers, and reactors.

FAQ

What Are the Biggest Differences Between 304 and 316 Stainless Steel?

The biggest difference between 304 and 316 stainless steel is that 304 stainless steel contains 18% chromium and 8% nickel, whereas 316 stainless steel contains 10% nickel, 16% chromium, and 2% molybdenum. This makes 316 stainless steel more durable and resistant to harsh environments and chlorides.

Which Type of Stainless Steel is Better for Marine Environments

Due to its higher resistance to saltwater corrosion, 316 stainless steel is the better option for a variety of marine applications. This is because of the addition of molybdenum.

Which Type of Stainless Steel is Better for Medical Devices?

316 stainless steel is the preferred type of stainless steel for medical devices due to its high resistance to corrosion. It is also more biocompatible than 304 stainless steel.

Is 316 Stainless Steel More Expensive Than 304 Stainless Steel?

Yes, 316 stainless steel is more expensive than 304 stainless steel, and the reason for this is due to its higher nickel and molybdenum content. It’s simply the better type of stainless steel, and it’s more expensive because of that.

Can 304 Stainless Steel Be Used Outdoors?

Although 304 stainless steel is fine for basic outdoor applications, beware that it is more prone to crevice corrosion and pitting than 316 stainless steel. This is especially the case in environments where the stainless steel will be exposed to high chloride amounts.

Conclusion: 304 vs 316 Stainless Steel: What’s the Difference?

The bottom line is that both 304 and 316 stainless steel have many different purposes that they are suitable for. With that being said, which of these two types of stainless steel you choose depends on your application. 304 stainless steel is much more cost-effective, but not quite as strong or corrosion-resistant.

On the other hand, if you’re looking for something much more durable, resistant to corrosion, and versatile overall, then 316 stainless steel is the better option. This is especially the case if you are willing to invest a little more money. Remember that VEVOR offers a wide variety of stainless steel products for projects of all sorts.