@vevor.official Wowww! 3-in-1 solution for your heat pressing needs!!🤩✨ By @LaserEngravingwithMatt #VEVOR #VEVORDIY #diytools #diyproject #art #tools #homediy #homeimprovement #VEVORTools #smallbusiness

♬ original sound – Vevor_US

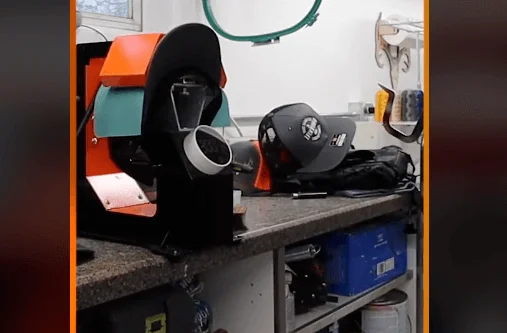

Creating personalized caps is easier than ever. Whether you are a small business owner or just a DIY enthusiast, the VEVOR Auto Cap Heat Press will professionally deliver your desired outcome with minimal effort. It is equipped with automatic operation and three interchangeable heating pads. So, this heat press tool is designed for efficiency and precision.

Recommended For Your Project

Table of contents

Major Features of VEVOR Auto Cap Heat Press

Efficient Automatic Operation

Unlike hand press machines that have to be monitored continuously, the VEVOR Auto Cap Heat Press is fully automated. One only has to insert the hat, set the time and temperature, and it automatically works. This means it saves you a lot of time but ensures consistency with a variety of projects.

Three Interchangeable Heating Pads

This equipment has three different types of heating pads, with which you can customize your hat size and type. It might be a structured cap or an unstructured cap. So, you can fit the machine according to your style. Hence, you get flexibility in all your sublimation or heat transfer vinyl projects.

User-Friendly For Beginners

Even if you are a first-time user of a heat press, the automated features and easy-to-read digital controls make it very simple. For experienced users, though, this machine ensures reliability and precision for professional-grade results.

Durable and Reliable

This machine can make a lot of hats that users can wear comfortably due to its excellent-quality making. The VEVOR Auto Cap Heat Press makes a hat that is great in quality and will go out long without breaking down after successive usage. Strong heating pads and a reliable digital control system mean you can make hats continuously.

Versatile For Multiple Uses

VEVOR Auto Cap Heat Press can also be used in other small heat transfer projects. From putting a logo on the front of a cap to adding a small pocket-sized area on a shirt, it’s versatile in its application with the different heating pads.

Accurate Digital Control

You can control both time and temperature through its user-friendly digital interface. With precise settings, you’ll achieve the perfect transfer every time, without the risk of scorching or underheating.

Compact and Space-Saving Design

Space can be an issue, especially if you are running a small business or working at home. The VEVOR Auto Cap Heat Press is compact in size, allowing for easy storage and usage without taking up too much space. Additionally, its lightweight will make it portable so that you can carry it to trade shows, events, or even anywhere you want.

Tips to Use This Auto Cap Heat Press

- Prepare the Hat and Design: Select the hat you want to customize and prepare your design. Make sure your design is of the right size for the front of the cap. The VEVOR Auto Cap Heat Press supports sublimation and heat transfer vinyl designs, so use either to suit your needs.

- Adjust the Heating Pad: The VEVOR Auto Cap Heat Press has three interchangeable heating pads. According to the size of your hat, choose the appropriate heating pad and attach it to the machine. This will ensure a perfect fit for your cap with even heat distribution and a flawless transfer.

- Set Time and Temperature: Using the digital controls, set the temperature to what is suitable for your hat’s material and the design you’re transferring. Generally, sublimation requires a higher temperature than HTV. Set the timer so that the design will stick to the fabric nicely.

- Place the Hat and Start the Press: Put the hat on the heating pad tightly. Position the design correctly. The VEVOR appliance will automatically start its automatic pressing function, with constant application of heat and pressure for the desired time period.

- Remove and Cool: Once the time has passed, the press automatically opens. The cap needs to be carefully lifted off to allow cooling down before one can handle the design. An image that is fully transferred should now be visible. It’s now ready to be worn.

Frequently Asked Questions

Can I use the VEVOR Auto Cap Heat Press for other apparel besides hats?

Yes, though it’s for caps, this can be used on small, flat surfaces like sleeves or shirt pockets for heat transfer.

What temperature do I need to set for sublimation transfers?

For sublimation, the ideal temperature setting is between 360 °F to 400 °F. But always test a small area if you are not sure of the material.

How long does the heat press process take?

It will take around 15 to 30 seconds, depending on the type of material and transfer involved. Digital control will of course ensure you get proper timing.

Final Thoughts

This auto cap heat press is really a change of game if you need to make high-quality custom hats. It comes with an auto-operation facility, multiple heating pads and a compact design. These things make it perfect both for personal and commercial uses.

You can start making your custom hats today and really revolutionize your brand or your sense of style. Order the VEVOR auto cap heat press and take the very first step toward professional-level customized looks.