If you’re looking for a reliable way to power your pneumatic tools, then a good air compressor is really the only way to go. Pneumatic tools and air-powered systems are used in a wide variety of industries, from construction and automotive to manufacturing, and even for DIY use at home.

With that being said, although air compressors are extremely useful for many different purposes, exactly which purposes they are best for really depends on the exact type of air compressor in question. This is exactly what we are here to talk about today, the different types of air compressors and what they’re best used for.

This is your complete guide to air compressor types, and today we’ll detail all of the most common ones and exactly what they’re used for. For instance, an air compressor like the VEVOR 80 Gallon Air Compressor, Due to its durability, versatility, and size, is suitable for many different applications, something you’ll find out more about below.

Table of contents

What Is an Air Compressor?

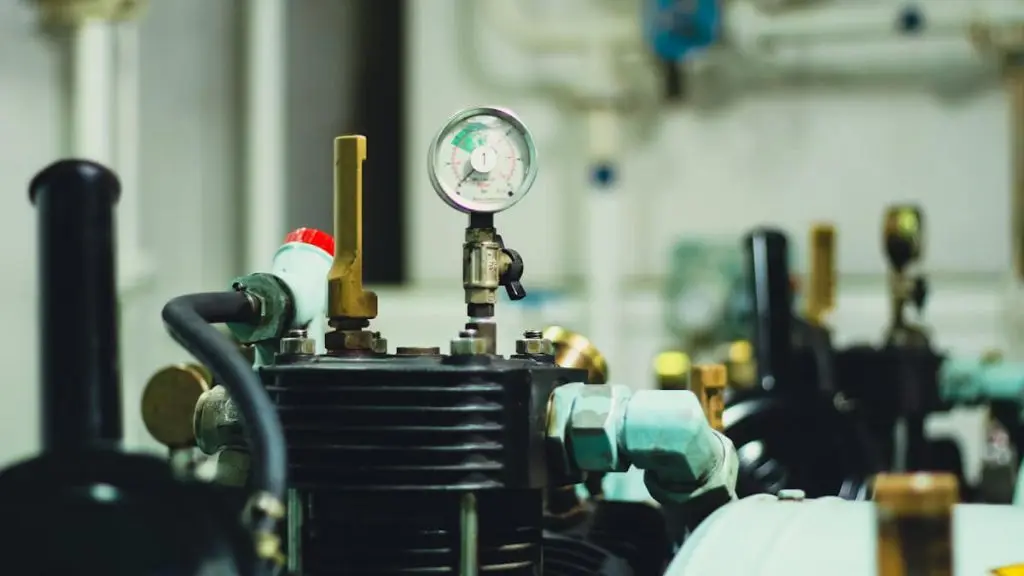

For those of you who don’t know, an air compressor is a special type of machine designed to compress air. To expand on this, air compressors intake air and then compress it to create highly pressurized air.

As you’ll see below, exactly how this happens depends on the exact type of air compressor in question. However, this pressurized air can then be used for a variety of purposes. The pressurized air can be supplied in a continuous flow, or it can be released in short bursts when it’s stored in a tank.

Depending on the type of model, air compressors may only allow for continuous flow, or if they have a tank, the air can then also be stored for future use. As you’ll see further below, there are many different types of air compressors, and which one you choose depends on the task you plan on accomplishing. Play

What Is an Air Compressor Used For?

Interesting to note is that air compressors are used in many different fields. For instance, air compressors are used in the construction industry to power tools such as concrete compactors, drills, and jackhammers, because they are able to provide consistent high-pressure air for demanding tasks.

Furthermore, air compressors are often used in automotive repair shops as well, as they are perfect for inflating tires and operating a variety of pneumatic tools that are used in shops, such as air-powered wrenches. Automotive shops may also use pneumatic tools to paint their vehicles.

Air compressors are also used in the manufacturing industry, as they power a variety of machinery and tools, especially to do with the assembly line. Particularly, oil-free air compressors are important in industries that require uncontaminated and clean air, such as the medical and food processing industries.

Air compressors can also be used at home by homeowners and DIY enthusiasts alike. They can be used for quick paint jobs, for powering nail guns, and for inflating tires as well.

Different Types of Air Compressors

Now that we know exactly what air compressors are and what they are used for, let’s move on and find out what the main types of air compressors are.

Reciprocating (Piston) Compressors

The first type of air compressor worth mentioning is the reciprocating compressor, also known as the piston compressor. This is one of the most common types, and it uses a series of pistons that are driven by a crankshaft to compress air within a cylinder.

These compressors can be either single-acting or double-acting, with single-acting models using one side of the piston to compress air, whereas double-acting models use both sides of the piston to compress air, therefore providing roughly twice the power.

Thanks to their design, reciprocating compressors are ideal for generating high amounts of pressure, therefore making them suitable for heavy-duty tasks, particularly in industrial and automotive applications. With that being said, they generally require frequent maintenance and are quite noisy as well. If you require a great air compressor with steady airflow, the VEVOR 80 Gallon Oil-Free Air Compressor is always a model worth considering.

Recommended For Your Project

Rotary Screw Compressors

Next, we have rotary screw compressors, which are best for continuous operation. Use two interlocking screws or rotors to compress air. This type of air compressor is generally found in industrial settings due to its quiet operation and high efficiency.

As the rotors turn air gets trapped in between them and is compressed in the process, therefore delivering air at a consistent pressure. Rotary compressors often come with oil injection systems for lubrication, although there are also oil-free versions available for environments that need clean air.

Thanks to their ability to operate continuously, rotary screw compressors are ideal for applications that require steady airflow, such as in factories, construction sites, and automotive shops.

Scroll Compressors

We then have scroll compressors, which use two spiraling elements, with one rotating and the other being fixed, which compresses air in between them.

The rotating motion traps and compresses the air inside of the spirals, which results in extremely efficient and quiet air compression.

Scroll compressors are usually used for small and medium-sized applications that require low noise levels and low levels of maintenance, such as in laboratories and for HVAC systems.

Scroll air compressors are highly valued for their reliability and smooth function, because they don’t have many moving parts compared to other types, such as rotary and piston compressors.

Centrifugal Compressors

Another commonly used type of air compressor is the centrifugal compressor, which is also known as a dynamic compressor. These use very fast-moving impellers to speed up the air velocity, and then convert this kinetic energy into air pressure.

These air compressors are ideal for producing large volumes of high-pressured air, which makes them suitable for industrial uses that require a constant supply of high-volume air.

This is especially useful in settings such as steel manufacturing facilities and chemical plants. Now, centrifugal compressors are very efficient and powerful, but they also require a lot of precise maintenance and are costly as well.

Axial Compressors

Next on the list, we have axial compressors, and these are generally used in aerospace applications where the constraints of space and levels of high efficiency are important. This is a type of air compressor that uses rotating blades to compress air as it moves along the axis of the compressor.

Axial compressors are able to generate high volumes of compressed air, but are generally only used for very expensive and high-budget projects. They are very costly and complex, and therefore aren’t used in many industries apart from aerospace.

Diaphragm Compressors

We then have diaphragm air compressors, which are best for applications that require 100% clean air. Instead of using a screw or piston, they use flexible diaphragms that compress air without any direct contact between the air and any lubrication used in the machine.

This makes them extremely ideal for sensitive environments, such as food processing, laboratory settings, and the pharmaceutical industry.

Rotary Vane Compressors

Finally, we have rotary vane air compressors, which use a rotor with sliding veins that move inside of a cavity. As the vanes expand and contract, they trap and compress air. This type of air compressor is best known for its high energy efficiency and very long lifespan.

One of the reasons for this is that rotary vane air compressors produce a lot less heat than both screw and piston air compressors, therefore providing a very reliable and steady flow of compressed air.

This type of air compressor is generally used in applications where moderate levels of consistent air pressure are required, such as for woodworking, printing, and other light-duty industrial applications. Although they might be less powerful than rotary screw compressors, they’re also quite cost-effective.

FAQs

Here are some of your most frequently asked questions about air compressors.

What type of air compressor should I use at home?

If you are powering nail guns, painting, or inflating tires, something like a portable reciprocating air compressor is generally the best choice due to mobility and its compact size.

Should I choose an oil-free air compressor or an oil-lubricated air compressor?

For basic at-home use, an oil-lubricated air compressor is recommended. These are ideal for a variety of heavy-duty applications and have much longer lifespans due to their lubricated components. However, oil-free compressors are best for environments where you need clean air.

How do I choose the best air compressor for my requirements?

To choose the right air compressor, you need to consider the type of task you need to perform. You then need to check the CFM ratings to ensure that they match or exceed the CFM requirements of the air tools that you have.

What are PSI and CFM in air compressors?

CFM stands for cubic feet per minute, and this is a measure of how much air the compressor can supply per minute, measured in cubic feet. On the other hand, we have PSI or pounds per square inch, which measures the amount of air pressure that an air compressor can generate.

Air Compressor Types: Final Thoughts

As you can see, there are many different types of air compressors, whether centrifugal, piston, Rotary screw, or anything else. The simple fact of the matter is that among all of the different types of air compressors out there, you need to choose the one that is most suitable for your work. Read our detailed descriptions of the air compressors above and make your choice. With all of that being said, remember that the extensive selection of air compressors from VEVOR should allow you to find at least one that suits your needs.