While using a belt grinder, precision and performance should be the two ultimate goals. Speaking of performance, running a belt grinder at an optimal speed is as important as choosing the right abrasive.

Various workpiece materials require different speeds to achieve optimal belt performance, stock removal rates, and productivity levels.

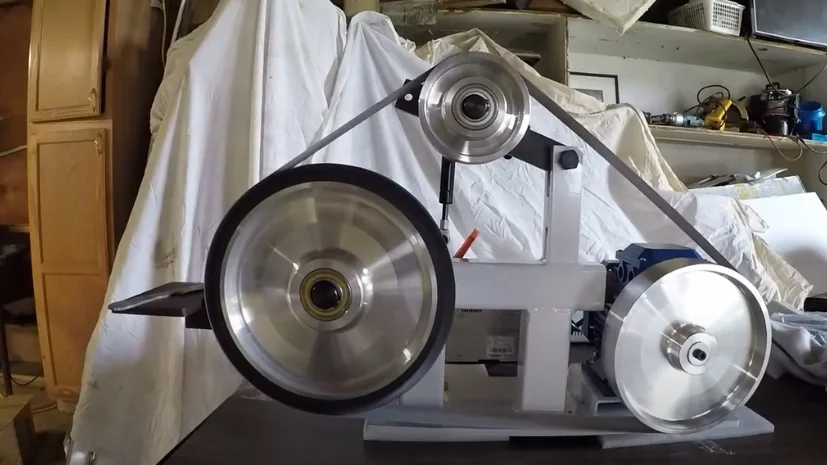

VEVOR 2Hp Variable Speed Belt Grinder comes with a high-quality belt and durable wheels, featuring a non-slip design and fast grinding speed optimal for several materials. The motor runs smoothly to ensure a uniform rotating speed between 0 and 2800 RPM.

But what does a grinder’s RPM, or surface feet per minute (SFPM), signify? How to find an optimal setting for a range of materials?

Table of contents

Understanding Grinder RPM

The abrasive belt on the belt grinder rotates at a specific speed that we express in RPM (revolutions per minute). Some manufacturers measure it in linear feet per minute or surface feet per minute (SFPM). It indicates the relative speed between the abrasive belt and the workpiece surface.

The grinder’s RPM plays a significant role in determining the efficiency, material removal rate, and overall performance of the belt grinder. The recommended RPM depends on several factors, including the type of sander, the size of the abrasive belt, and the workpiece material you use.

RPM and Grinding Precision

But how does grinding RPM influence the precision in your work?

A greater belt speed results in an increased cut rate, as the rise in speed introduces more cutting edges to the workpiece. The goal in each case is to maximize SFPM (surface feet per minute) to enhance production while keeping heat generation to a bare minimum.

So, what happens if you set an incorrect grinder RPM?

Setting a lower RPM than optimal may result in wheel wear and breakdown of the wheel form. On the contrary, a higher-than-recommended cutting speed will cause the machine to overheat and burn.

Top Grinder RPM Factors Explored

An in-depth understanding of a grinder’s RPM is necessary to obtain the maximum return on your investment. Several factors affect the belt speed; let’s list them down.

- Mechanical Parameters: Adjusting parameters, like grinding machine speed, feed speed, and cutter head diameter, will have a direct impact on the abrasive cutting speed. For instance, the higher rotational speed and feed rate of the grinder results in a higher grinding rate of the material.

- Motor Power: The ability of the motor to drive the belt at a certain speed will impact the grinder’s RPM. Motors with high powers are capable of rotating the belt at high speed without overheating.

- Characteristics of the Abrasive Belt: It only makes sense that large belts cover more surface area per rotation. Therefore, the dimensions of the abrasive belt, including its width and length, will impact how quickly it moves across the workpiece. Moreover, insufficient tension in the abrasive belt can cause it to slip, ultimately affecting its speed and grinding performance.

- Environmental Conditions: The temperature and humidity have an impact on the stability of a grinding tool, resulting in altered grinding and cutting speed.

Grinding RPM and Grinder’s Performance

Every project and the workpiece material you are working with poses different speed needs. For instance, lower grinding RPM on hard materials will leave burrs and blemishes on the end product. However, you might need a lower grinding and cutting speed to work on high-precision optical devices.

The performance of the machine depends upon its RPM, which an operator sets. So, your skill and experience with belt grinders are also crucial in bringing precision to your work and increasing the tool’s efficiency.

VEVOR Belt Grinder: A Game-Changer

VEVOR belt grinder with its advanced features is a game-changer and addresses all the grinder rpm factors including speed, motor power, and abrasive belt problems. Let’s discuss some features in this section that it possesses.

- 3-in-1 Belt Grinder: Circular grinding, arc grinding, flat grinding

- The variable rotating speed of 0-2800 rpm makes it fit for different application usage.

- The belt sander comes with a high-quality abrasive belt with durable wheels featuring a non-slip design that reduces friction and ultimately aids the grinder’s RPM.

- It comes with a 1500W powerful motor that is capable of rotating the belt at high speed without impacting the grinder’s RPM.

- In continuous operation, it incorporates a radiator to aid in dissipating heat, effectively addressing potential heating issues. It will result in less wear and tear and enhanced revolutions per minute.

- Its high-strength steel plates contribute to its long service life, making it perfect for heavy-duty work.

- It is easy to operate as it comes with a belt adjustment handle, and the wheels are easy to assemble and disassemble.

Calculating Belt Speed for Optimal Results

Understanding belt speed calculation is crucial for achieving optimal results with your belt sander. You must determine whether to set the speed to low or high based on the material and your specific needs. There are three important things you need to consider when calculating the grinder’s RPM:

- Speed of the motor

- Diameter of the drive wheel

- Rotational Speed Control

The speed of a belt grinder depends on the motor’s RPM and the size of the drive wheel. A 1400 RPM motor with a 10 cm drive wheel is ideal for delicate tasks like watch-making and precision grinding. In contrast, a 2800 RPM motor with the same drive wheel size generates higher belt speeds, suitable for more aggressive cutting or grinding tasks, such as hard steel or wood.

You can customize the belt speed by adjusting these parameters to suit your requirements for different materials and applications.

The formula to calculate the cutting speed for a belt grinder is:

SFPM = RPM x .262 x D

Where:

SFPM = surface feet per minute

D = diameter of the contact wheel in (inches)

RPM = revolutions per minute of the wheel

You can use this equation to determine the optimal SFPM for different types of workpiece materials, which will help you achieve the desired grinding results.

Choosing the Right Belt for Your Grinder

Choosing the right belt for your grinder is crucial alongside the grinder RPM, as it can make a significant difference in the quality of your work.

The material you are working with is a critical factor to consider when choosing the belt for your grinder. For example, if you are looking to polish a material, then choosing belts with higher grits is better.

On the other hand, if you want to remove stock and provide more definition to the workpiece, lower grits might work better. Therefore, choosing the right belt grit based on the material and the desired outcome is necessary to achieve optimal results.

It is essential to ensure optimal performance and avoid undesired results by ensuring that the belt fits securely over the grinder and can handle a range of different RPM speeds without slipping, especially at high speeds. The VEVOR grinder provides different settings so that all types of belts fit without any additional problems.

Belt for Grinder: Exploring Varieties for Different Applications

VEVOR belt grinder offers versatility by accommodating all types of belts, making it an excellent option for all your needs. Selecting the right belt size and grit will help you with various grinding tasks and grind metals, wood, acrylic, and other materials with ease.

Its ability to handle tool polishing and a range of other applications makes it a reliable and efficient tool for professionals working with diverse materials. If you require a dependable grinder that effectively manages different materials, the Vevor grinder stands out as an excellent choice.

Abrasive belts are available in various adhesive grits, and each grit is suitable for a specific type of job. Let’s discuss each belt in detail for different applications:

Aluminum Oxide Belts

The reddish-brown colored aluminum oxide belts are the most popular kind of sanding belts and are ideal for general use. They are affordable, durable, and ideal for materials like wood and metals like brass, chrome, copper, bronze, and titanium.

Zirconia Aluminum Belts

Zirconia aluminum belts, which are blue, are about five times stronger than aluminum oxide belts and suit best with high-pressure sanders. They are also self-sharpening, which increases their lifespan. If you want to target stainless and tough metals, these belts are the best fit for your use.

Ceramic Grit Belts

Ceramic grit belts are also self-sharpening and have the longest life of all sanding belts. Since these belts do not generate heat while grinding, they are suitable for heat-sensitive jobs.

Summing Up

In a phrase, belt grinding is an art of precision and balance. Running the machine too fast can ruin the temper of the metal and burn out the bearings on smaller contact wheels. However, setting a lower grinder’s RPM will cause wear and tear on the components. So, you have to adjust the speed throughout the process for a more seamless end product.

The efficiency of the process also depends on the model you use. VEVOR offers high-powered and durable belt grinders at affordable prices. They make it easy for the operator to retain an optimal RPM for satisfactory results. Check our website before they stock out