If you would like to start working with wood, but you don’t know which tools to buy first, then you have come to the right place. Today, we are here to compare two of the most commonly used tools in cabinetry, joinery, carpentry, and all sorts of woodworking professions.

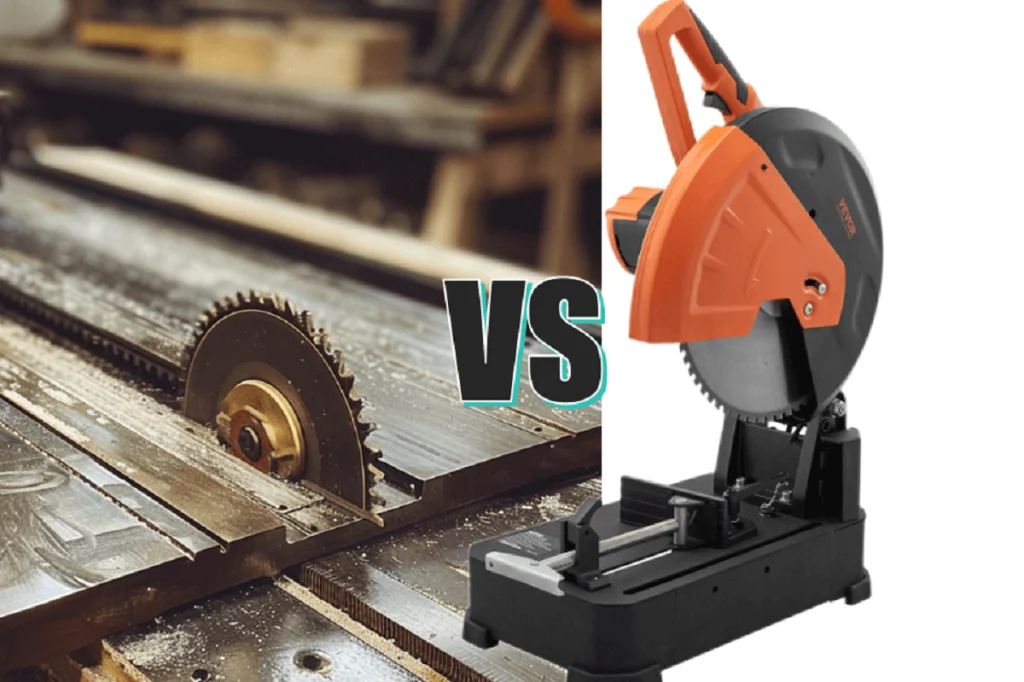

These two saws include the chop saw and the table saw. Yes, both are saws with circular blades designed mainly to cut wood, but there are some pretty major differences between them that you should be aware of.

Table of contents

A Basic Introduction to Chop Saws and Table Saws

Before we get to comparing these two types of saws, let’s first do a quick overview of what each saw is.

What is a Chop Saw?

First, we have the chop saw, a very durable and versatile tool designed for making straight cuts through many different materials, with this model from VEVOR being a prime example. A chop saw is specifically designed to make straight cuts with great precision.

Although a chop saw can certainly be used for cutting wood, interesting to note is that cutting metal is one of its main uses.

There are models that have blades with teeth made for cutting wood as well as abrasive discs that excel at cutting metal. With a chop saw, the blade sits on an arm in a vertical manner, and the user simply pushes the blade down through the piece being cut.

What is a Table Saw?

We then have the table saw, which is a staple in the world of woodworking, and often considered a carpenter’s best friend. A table saw consists of a large and circular blade that sticks up through a table, hence the name, table saw.

This table can be made out of various materials, such as cast iron, steel, or aluminum, each of which have their advantages.

The blade is fixed below the table, although it can be adjusted for height and angle, and the user rests the wood on the table, and pushes it through the blade, which spins at high speeds. Table saw blades can differ in size and tooth count depending on the specific purpose.

Why Making the Right Choice Matters

Choosing the right type of saw is important for a number of reasons. First and foremost, it’s all about functionality. As you can tell from the descriptions of the respective saws, they aren’t all designed for the same purpose.

The tasks that one saw excels at, the other might not be able to do at all, or at least not very well. The performance of the tool in question, as well as the final result, depends on it. Furthermore, because different saws have different strengths, drawbacks, and functions, safety is also a paramount concern. Using the wrong saw for a job can have serious safety repercussions.

Chop Saws and Table Saws: Shared Similarities

Now that we know what both of these saws are and what their basic features consist of, let’s take a look at the things that make chop saws and table saws similar.

Working Material

One of the main similarities shared between chop and table saws is the materials they are designed to work with. Now, we know that we said that table saws are primarily woodworking tools, whereas chop saws are primarily metalworking tools.

However, keep in mind that both tools allow for different blades to be used, with table saws allowing for blades that can cut tile, metal, plastic, wood, and more, with the same also being true for the chop saw. Essentially, they can both be used for the same materials.

Safety Features

Another similarity between these two types of saws is that they generally feature a variety of safety mechanisms to ensure that you don’t end up losing a finger.

Most of them have special emergency stop mechanisms that automatically stop blade motion if the tool comes into contact with something soft, like human flesh. Both of them generally have blade guards as well, to keep the blade hidden when not in use.

Adjustability

Yet another feature shared by both of these saws is that they have adjustable features. Chop saws can allow you to change the depth of the cut, although they often don’t allow for any other kinds of adjustments. Some may allow you to adjust the angle of the base, therefore allowing for angled cuts.

Table saws are also highly adjustable in nature, often allowing for the angle of the blade as well as blade height to be adjusted, and even the angle or position of the fence.

Electric Power Source

One of the simplest similarities shared by both tools is that they use electricity to function.

They Both Cut

Although in slightly different ways, the core similarity here is that both table saws and chop saws are tools designed to cut various materials with circular blades.

Chop Saws and Table Saws: Main Differences

Although the two saws share some similarities, there are also some notable differences between table saws and chop saws.

Orientation of the Blade

A big difference here is that the blade orientation is different. Interesting to note is that on a table saw, the blade is fixed on the bottom, and sticks up through the table. On the chop saw on the other hand, the blade is fixed to an arm above the surface, with the blade moving down through the wood. The orientation of the blade, while vertical in both cases, is different.

Main Function

The really neat thing about table saws is that they are super versatile as to what they can do. They can make a wide variety of cuts, and they are super adjustable. This is why many people consider the table saw to be the best friend of a woodworker. Chop saws on the other hand are much less versatile, and the only thing that they’re really good for is making straight and quick cuts, albeit in a repeatable manner.

Size and Portability

Worth noting is that there are a few different types of table saws in terms of size, including miniature table top table saws, portable table saws on stands, and full size cabinet table saws that aren’t portable at all. This is another reason why table saws are so versatile. That said, chop saws tend to be much more versatile and portable in the sense, as they’re much smaller and lighter. They’re perfect for use on the job site.

Accuracy and Precision

Chop saws, while known for having decent accuracy, aren’t the most precise of all saws, especially when compared to a table saw. This is likely because table saws allow for much more refined adjustments to be made.

Size of the Material

Table saws, especially larger models, can handle very large wood stock, and other materials. However, chop saws are fairly limited in terms of the size of the material that they can handle.

Chop Saw Uses

Let’s take a quick look at the main uses of the chop saw, and as you can see, there are quite a few.

Straight Cuts

The number one use of a chop saw is to make straight cuts, simple straight cuts and nothing else. If you need a quick and efficient cutting tool, then a chop saw works very well.

Molding and Framing

If you are working on molding and framing, then a chop saw is a fantastic tool to use. This saw can make fast and clean cuts so you can easily create frames and do molding for your home.

Masonry and Metalwork

If you have the right abrasive discs, chop saws can also be used to cut various metals and pieces of masonry down to size.

Repetitive Cutting

Perhaps the biggest advantage of the chop saw is that it is able to make repeat cuts with ease, so you don’t have to keep making adjustments.

Table Saw Uses

Let’s now take a look at what table saws are best used for.

Crosscutting

If you have a good miter sled, you can easily make accurate cross cuts across the width of a piece of wood using a table saw.

Rip Cutting

Perhaps the number one main function of a table saw is to rip boards, otherwise known as making rip cuts. This is when a board is cut lengthwise, turning one wide board into two narrower boards.

Bevel and Dado Cuts

What’s neat about table saws is that because the blade angle can be changed, they can be used to make bevel cuts. Furthermore, thanks to being able to handle many different types of blades, a table saw can also cut rabbets, dadoes, and other cuts used in joinery.

Repetitive Work

Table saws, due to having an adjustable fence, are also ideal for repetitive work.

Pros and Cons of Chop Saws

Chop saws have both pros and cons worth noting.

Pros

- A lot of power

- Good for repeat work

- Portable

- Very easy to use

- Good for straight cuts

- Works for many materials

Cons

- Only makes straight cuts

- Not ideal for large materials

Pros and Cons of Table Saws

Table saws also have advantages and disadvantages worth considering.

Pros

- Can make many types of cuts

- Many sizes available

- Ideal for repetitive work

- Good for complex tasks

- Can handle large stock

Cons

- Take up a lot of space

- Can be dangerous to use

FAQs

Who is a Chop Saw Best For?

If you need to make straight, quick, and repetitive cuts through metal, masonry, and wood, a chop saw is ideal.

Can a Table Saw Replace a Chop Saw?

Yes, everything that a chop saw can do, a table saw can do too. However, chop saws come with more blade options for metal and masonry, with table saws usually being best for wood cutting.

Do I Need Both a Chop Saw and Table Saw

If you plan on working with wood, masonry, and metal, and you have complex tasks that require you to make many different types of cuts, then having both is recommended.

Chop Saw vs Table Saw: Choosing the Best One for You

At the end of the day, both table saws and chop saws are fantastic tools. They are both useful and versatile in their own rights, and now you should know how to choose between them. What needs to be said as well is that if you are looking for a good selection of table saw, VEVOR is the place to be!