Regardless of how careful you are, your commercial ice maker can have a lot of problems. Cleaning commercial ice machines is crucial for hygiene, productivity, and durability. By doing so, you’re ensuring high-quality, safe ice while minimizing the risk of equipment malfunctions.

Here’s what you need to know about preventing bacterial infections and safeguarding your machine’s heart. Getting those cubes rolling in perfection is all about elevating your ice game. It’s time for a frosty performance maintenance adventure!

This article will walk you through cleaning an ice machine step-by-step, ensuring your customers are safe.

The Top 10 Tips for Cleaning a Commercial Ice Machine

Despite your best efforts, your commercial ice maker can still have many malfunctions despite your careful handling. Most issues relate to water flow through the machine to function properly.

Keep your commercial ice machine running smoothly with these ten cleaning tips.

- Unplug and turn off: Keeping the power off during ice machine cleaning prevents accidents.

- Follow the manufacturer’s instructions: The instructions are specific to your machine. Before cleaning the ice machine, read the user manual.

- Gear Up: Wear gloves and safety glasses when cleaning; cleaning agents are harsh. During the ice machine cleaning process, make sure you’re wearing the right gear.

- Clear the Ice Bin: Keeps your workspace clear and keeps water and cleaner mix away from the ice. Avoid wasting ice by using or relocating it.

- Make Sure All Parts Are Clean: Residues can build up in various parts, affecting performance. Ensure the ice bin, water distribution system, and evaporator are clean.

- Always approved cleaners: Chemicals can damage the machine or leave residue on the ice. Make sure you stick to the cleaners the manufacturer recommends.

- Evaporator descale: Heat transfer efficiency can be reduced by scaling. The evaporator coils should be descaling with a solution.

- Keep the ice bin sanitized: You can get bacteria in the bin. Regularly disinfect the ice bin with a food-safe sanitizer.

- Replace your water filters: Filters trap impurities, but they can breed bacteria if they don’t get replaced. Maintain your water quality by commercial ice machine maintenance and replacing your filters on schedule.

- Maintain Ice Thickness: Production and quality are affected by ice thickness. To adjust ice thickness periodically, consult the user manual.

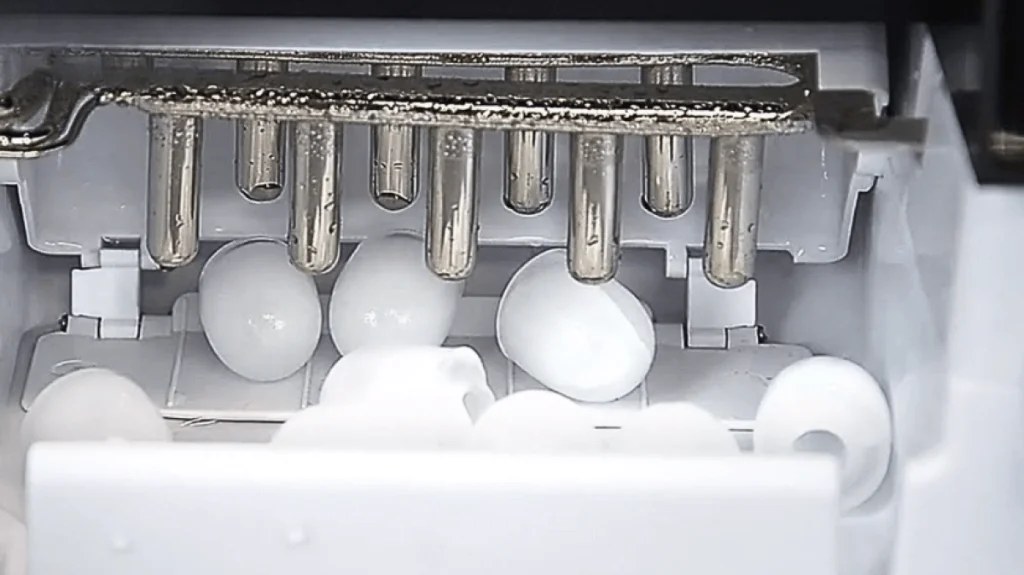

Understanding the Anatomy of a Commercial Ice Maker

How often do you clean the ice machine? Commercial ice machines need to be cleaned properly to ensure optimal performance and hygiene. Here’s what you need to clean:

- Distribution system: A mineral deposit or biofilm can affect ice quality and water flow. Remove and clean the water distribution tubes and nozzles using a good cleaner.

- Condenser: The condenser coils can’t dissipate heat if they’re dusty. Use a coil cleaner to remove stubborn dirt after you vacuum or brush away loose debris. Make sure the power is off while you’re cleaning.

- Evaporator: You can lose heat transfer efficiency when building scale and minerals. Make sure the evaporator coils are descaling. Make sure you follow the instructions from the manufacturer.

- Filtration system: Ensure you replace your water filters according to the manufacturer’s instructions. Prefilters need to be cleaned and inspected regularly.

- Seals and gaskets: It’s easy for residue to accumulate, ruining the seal. Using a mild solution, wipe gaskets and seals. Look for wear and damage.

- Drainage System: Drains can grow mold and bacteria. Ensure proper water drainage by cleaning the drain pan and lines. Sanitize and clean with a mild cleaner.

- Surfaces on the outside: The exterior can get dusty and grimy. Use a damp cloth and mild cleaner to clean the exterior surfaces.

When you regularly clean your commercial ice machine, you’ll keep it running smoothly, making delicious and sanitary ice. For specific cleaning instructions, check the manufacturer’s instructions.

How to Clean a Commercial Ice Machine: Step-by-Step Guide

While ice machines’ maintenance requirements vary depending on the vendor, most follow a similar process. Here are some general ice machine cleaning instructions, but consult your machine’s manual.

- Getting all the ice out is important before cleaning and sanitizing the ice machine. You can do it two ways. Once the ice drops from the evaporators, you can turn the power on after the harvest cycle or let the ice melt completely.

- Once that’s done, press your machine’s clean or wash button.

- Press the button, then add the scale remover. Check your service manual to see how much cleaner solution the ice machine needs.

- The ice machine cleaning cycle usually takes 20–45 minutes, so you must disconnect the power.

- Once that’s done, you must clean the rest of the parts. To find their correct locations, check your ice maker’s service manual. If you have a flaker or nugget ice machine, they will have extra parts that must also be cleaned.

- Mix cleaner and warm water according to your service manual. You usually mix 1 gallon of water with 16 ounces of cleaner.

- You have to clean all these parts with half the solution. Use a nylon brush, sponge, or cloth to scrub off dirt and grease. If the parts are heavily scaled, soak them in the solution.

- The evaporator and ice bin can be cleaned with a nylon brush or cloth while these parts are soaking.

- Dry these soaked parts properly after rinsing them with clean water.

Common Challenges and Troubleshooting Tips

You might encounter these challenges and problems when cleaning an ice machine:

Water Leakage Inside the Machine

This can happen if there’s a leaky valve somewhere in the machine. It might cause larger cubes to jam up the system.

Solution: Ensure your ice machine is cleaned and doesn’t have any loose connections or bad clips by checking it regularly.

High Water Temperature

When the water temperature is too high, the ice machine slows down or stops working if the water is too hot.

Solution: While cleaning the ice-machine, ensure the water temperature.

Overheated room

If you’re using one, an ice maker depends entirely on the room temperature in which it’s placed. A high room temperature makes the machine work harder, making less ice.

Solution: A room kept too warm for too long might cause repeated breakdowns. Make sure there’s a proper ventilation process in the room.

Low water flow

Too little water will result in uneven or smaller cubes instead of the right shape. The system could be blocked by a blockage in the line or something else.

Solution: It’s important to check the flow of your plumbing and make sure your filter isn’t clogged before cleaning the ice machine.

The Importance of Regular Maintenance for Long-Term Performance

The Food and Drug Administration regulates commercial ice machine cleaning. Food is considered ice. In particular, the FDA inspects:

- Plumbing to keep water and ice clean,

- Keeping the water clean and safe

Hospitals, restaurants, hotels, and stores have to have ice machines inspected by local health departments.

Benefits Of Cleaning Commercial Ice Machines Regularly

- Clean the ice machine to protect you from dangerous bacterial growth and contamination

- Cleaning frequently prevents biofilm from forming.

- It’s hard and expensive to remove biofilm once it’s established.

- Regular ice-machine cleaning can protect you from high repair cost

- Cleaning ice machines efficiently keeps your system.

Elevate Your Business with VEVOR’s Commercial Ice Makers

With VEVOR commercial ice machines, you get different types and weights of ice machines. That ensures auto cleaning of ice machine with high-quality water drain system for bar and home markets.

Built-in, freestanding, or under-counter, an electric drainage pump can effectively drain melted ice. Blue light strips make it easy to see ice cubes. Everything you need includes water supply hoses, ice scoops, hose connectors, and draining hoses.

Features

- Friendly Design

- Offer Touch Screen Facility

- Storage and Yielding of Large Ice

- Powerful Compressor

- Built-in Stainless-Steel Body

Conclusion

It’s essential to have an ice machine in your food service business. Maintaining your ice maker’s efficiency involves regular ice machine cleaning. It’s recommended to clean every six months by your local health department and manufacturers.

Commercial ice machine maintenance demands only clean and sanitized ice machines with specialized cleaners. Using the wrong solution or chemical combination can leave you with dangerous biofilms. Pathogens grow quickly in biofilms. VEVOR ice machine provides reliable and pristine ice production that you can’t get anywhere. Clean your ice-machine regularly. Choose the VEVOR commercial ice machine and make your ice shiner brighter!