Different Types of Press Punch Machines

Let us have a look at the different types of press punch machines:

Hydraulic Punch Press

This machine uses a hydraulic cylinder to power the ram. It is controlled either by a valve or by both feedback and a valve. The valve-operated presses execute one stroke operation. It means the ram will move up and down on command.

Mechanical Punch Press

It is one of the most popular punch press machines so far. Mechanical punch presses are of two types. It can be based on a braking or clutch system. However, some clutch presses are dangerous to operate. Therefore, they are prohibited in many countries.

Servo Drive Turret Punch Press

This system combines the clutch and brake technology with a hydraulic ram-operated system. It minimizes operating costs and boosts performance and reliability. Moreover, this system is easy to maintain and does not need an oil-cooling or hydraulic chiller. It is a cost-effective and energy-saving technology.

Pneumatic Punch Press

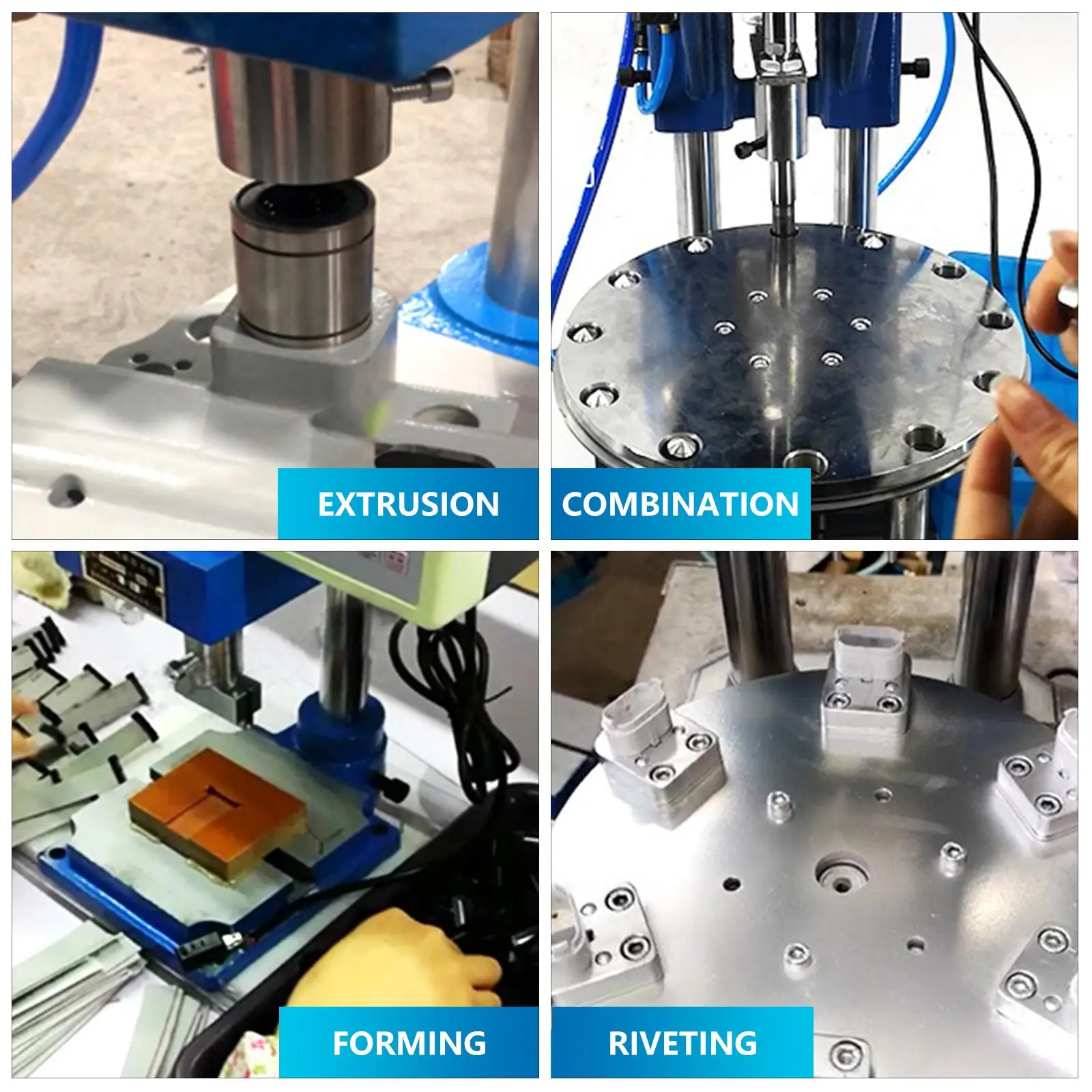

The pneumatic press can operate at incredibly high speeds. These easy-to-use and versatile machines require low tonnage and are ideal for small operations. For instance, VEVOR Vertical Single Column Pneumatic Press Machine is great for riveting, swaging, and marking. Moreover, it is also cost-effective and offers superb results every time.

How Does It Work?

Metalworking manufacturers use manual or automatic feeders for inserting metal sheets into a punch. This punch lies between the main die and its surface. The press inclines onto the metal sheet through compressive force. It presses the sheet into the pre-set mold to get the desired shape.

Industries that aim to lead the competition in 2023 should not leave any stone unturned to stay up-to-date with the latest technologies. And the most popular being the press punch machine. It is a machine press that helps in cutting holes in different materials.

A press punch machine deforms a metallic piece by applying appropriate pressure to the attached die. The main function of this innovative machine is punching, piercing, notching, perforating, and slotting. Do you also plan to get a press punch for your factory? Then, you have reached the right place. Here is a crisp guide with all the essentials for you.

List Of Top 5 Press Punch Machines

Here are the best 5 press punch machines to look for in 2023.

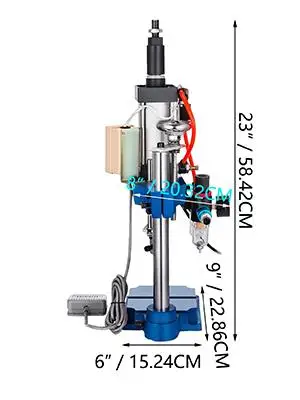

1. VEVOR Vertical Single Column Pneumatic Press Machine

This advanced pneumatic punch press comprises high-performance cylinders. Moreover, the noise-free hydraulic system, high-precision rotational resistance guide plate, and guide rod add to the qualities of this machine.

It has a theoretical output pressure of 1121-1962 N / 114-200 kg. Its actual output is around 80% of the theoretical output. Users also appreciate its high-precision, energy-saving, and low-production costing features.

Features and Performance

High Precision: This machine has a high-precision rotational resistance guide plate and rod. It can seamlessly adapt to higher speed accuracy impact load.

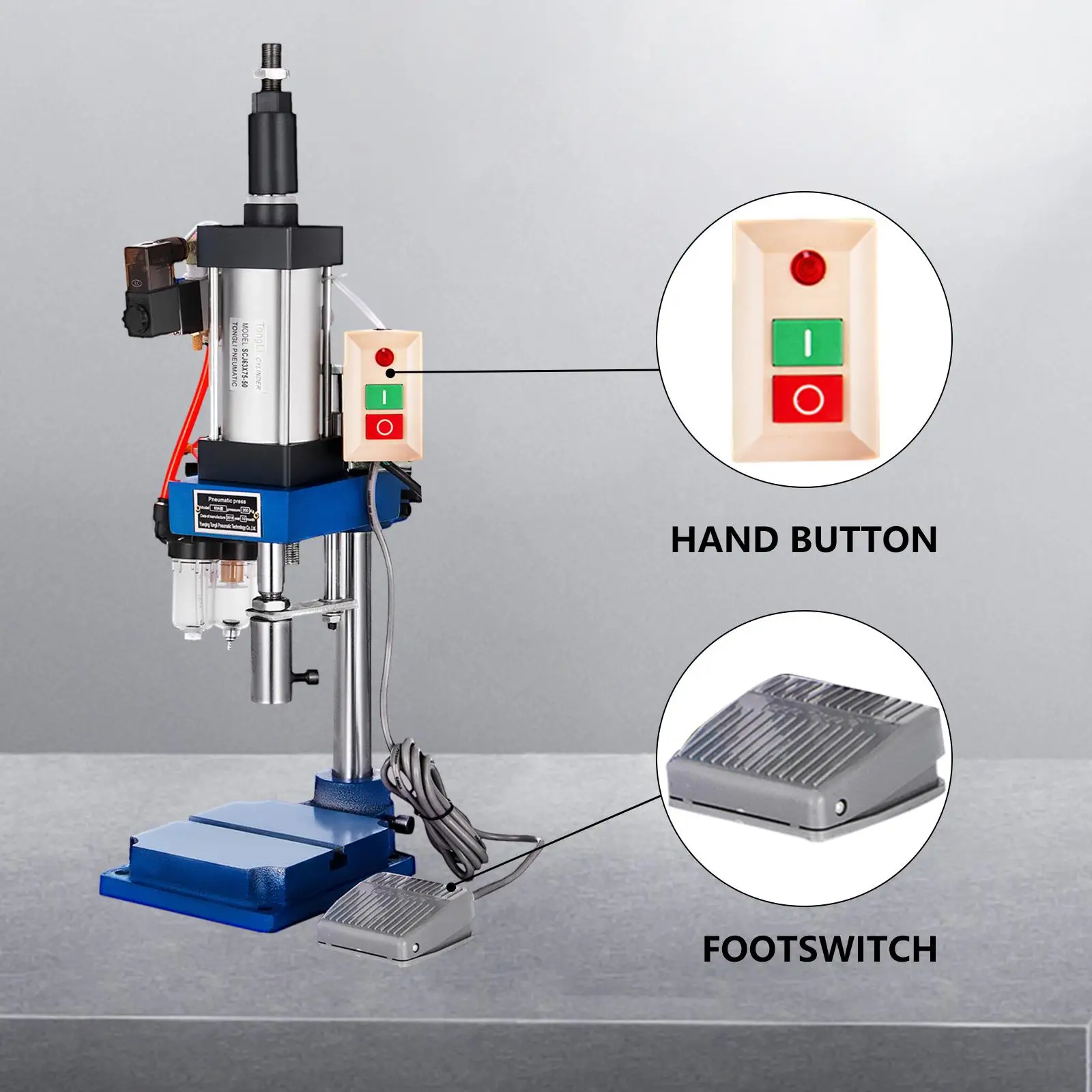

Hand Buttons and Foot Switch: You can use manual 6 feet / 1.8 m foot switch stamping control for more effective results. It also offers enhanced device protection and reliable operations.

T-Groove Base: The effective 9″ x 6″ size T-shaped groove HT200 cast iron base adds to the machine’s durability. Moreover, it is easy to install and disassemble.

Brand: VEVOR

Voltage: 110V AC

Power Source: Pneumatic

Operation Pressure: 0.4-0.7 Mpa (4-7 kg/cm², or 110-140 PSI)

Actual Output: About 80% of Theoretical Output

Die Hole Diameter: 0.63″ / 16 mm

Control Form: Manual

Layout Form: Vertical

Pros:

- It offers brilliant precision

- The machine has a humanized design

- The quick adjustment feature is the highlight of this product

- It is a multipurpose punch press machine

- Simple and easy-to-perform operations make it one of a kind

2. Bonvoisin Electric Hydraulic Hole Punch Machine

This amazing hole punch machine is portable and very convenient to operate. The auxiliary handle allows you to use this tool by hand as well. Bonvoisin Punch Machine is ideal for aluminum or copper plates. It can punch holes in the metal thickness of 0.11″ to 0.31.” Moreover, you can also use it on a steel plate of 0.11 to 0.23 thickness.

Features and Performance

Precise Positioning and Fast Punching: The high-power motor offers a brilliant punching speed of 2 to 3 seconds. Every punch is accurate, fuss-free, and emission-free.

Versatile Product: Users also prefer this punching machine for its versatility. It can be used on different ferrous and non-ferrous materials.

Brand: Bonvoisin

Voltage: 110 V

Power: 900 W

Output Force: 10 T

Aluminum / Copper: Thickness up to 31″

Iron / Steel: Thickness up to 23″

Weight: 18 kg

Package: Iron Box

Pros:

It is a reliable and durable product

This machine is affordable

3. Harsle JH21 Pneumatic Punching Machine

This machine comes with a welded steel plate body. An integral frame structure with low deformation and good steel properties are the other highlights of this product. Harsle JH21 Pneumatic Punching Machine offers high dynamic preciseness in a spacious workspace. So, if you are into automated production and precision machining, this can be the right machine.

Features and Performance

Wet Friction Clutch Brake: This machine has an advanced wet friction clutch brake that helps prevent accidents and mishappenings.

Overload Protector: A robust overload protector is another highlight of this machine. It helps maintain the efficiency of the operations.

Brand: Harsle

Normal Capacity: 250 KN

Die Set Height: 250 mm

Motor Power: 3 KW

Pros:

It offers brilliant efficiency and performance

This machine is great for large-scale projects

4. INTBUYING Pneumatic Punch Machine Press

It is another efficient punch press machine that promises superb efficiency at affordable rates. INTBUYING Pneumatic Punch Machine Press is powered by compressed air. It is easy to operate, great for manual operations, and can minimize labor.

Features and Performance

Complete Package: It is an affordable, simple machine that promises noise-free great performance, and energy efficiency.

Output Adjusting Feature: You can adjust the output by resetting the air pressure. It helps in reaching the desired pressure for a high yield.

Brand: INTBUYING

Voltage: 110V

Power Type: Pneumatic

Pressure: 660lb/300kg

The die hole diameter: 0.78inch/ 2 cm

Working Height: 5.5″/14cm

Control Form: people work

Layout Form: Vertical

Pros:

- It features a microcomputer control system

- The product offers both hand controls and footswitches

5. Boschert Punching Machine

This twin or tri series press punch machine has 2 to 3 independent punch heads. There are up to 16 tools in the twin series machine and about 24 in the tri series machine. The user-friendly software makes this machine super easy to understand and operate.

Features and Performance

Advanced Software: This machine has advanced software that can handle large parts’ automatic flipping, turning, and repositioning.

Multipurpose Machine: It is a multipurpose machine that can be used in versatile projects and materials.

Brand: Boschert

Sheet Length: 32″

Punching Force: 36 tons

Punching Speed: 400 spm to 800 spm

Punch Diameter: 4″

Stroke Length: 3.54″

Electrical Consumption: 230/460 volts

Pros:

- It is an affordable machine

- Durability and reliability are their major highlights.

So, considering the above options, VEVOR Vertical Single Column Pneumatic Press Machine is the best of all. It is a robust machine with a perfect blend of high performance, efficiency, convenience, and affordability. Other machines offer decent performances but can have higher maintenance costs in the long run.

What Should You Look for When Buying a Press Punch Machine?

Here are the major factors you should consider while buying a press punch machine.

Price: Experts recommend choosing a punch press that offers superb performance and high-quality output at a reasonable price, like the VEVOR Vertical Single Column Pneumatic Press Machine. Going for a very expensive machine can cost you dearly in the long run. Similarly, investing in an extremely cheap machine can compromise your final quality. So, make a wise choice here.

Type of Punch Press: Punch press machines are different types and offer different functions. So, knowing it will help you select the right machine for your manufacturing unit. You can also consult an industry expert to learn more about it.

Finish: You should also consider the finish quality and total post-production cost while planning to invest in a punch press machine. Experts say that pneumatic and mechanical presses are known to offer the best results so far.

Are Press Punch Machines Worth It?

A punch press machine is a versatile tool that produces uniform, precise products efficiently and quickly. It is a great machine for both small and large production processes. It is usually combined with various metal working procedures like finishing, assembly, and machining to get the desired results.

You can perform functions like punching, blanking, embossing, casting, flanging, and bending. All these factors make press punch machines a must-have and worth investment for progressive industrial units.

FAQ About Press Punch Machine

Q. What is the purpose of a punch press machine?

This machine can alter the shape or size of a ferrous or non-ferrous metallic sheet by applying pressure to the die.

Q. Are press punch machines noise-free?

Yes. Branded punching machines like that of VEVOR’s are noise-free.

Q. How should you maintain a punch press machine?

You can do it by checking its lubrication, air pressure, inching stroke, clutch magnetic valve, and emergency button.