Introduction

Do you find it difficult to choose between a hand tamper vs plate compactor for your construction project? Compaction is very important in constructing the proper foundations and solid buildings. Correct compaction on construction projects leads to reduced settling and increased stability. But which tool will it be? This comparison aims to help you make a well-informed decision. Hand tampers are beneficial when precision is needed in tight spaces but are more tiring. Moreover, plate compactors cover larger areas quickly, thus saving labor and time. This article aims to guide you in choosing the best tool for your situation by unveiling every difference. Let’s uncover!

Table of contents

Hand Tamper

A hand tamper is a manual device for earthworks like compacting soil, gravel, or asphalt during road building. Usually, it is a flat metal plate fastened on a handle. This action involves pressing the plate on the material’s surface to compact it.

Working Mechanism

You start by placing the steel plate over the area to be compacted. Then, you swing the hammer repeatedly using the handle. The repeated striking of the material underneath causes it to compact and build a steady base.

Pros

Notable advantages of the hand tamper are as follows:

Versatility: Hand tampers are installed for different purposes that include soil, gravel or asphalt compaction.

Low Cost: Unlike plate compactors which are relatively expensive, hand tampers are affordable to buy or rent for home projects and occasional site use.

Portability: Hand Tampers are lightweight and easy to move across different places of your fieldwork on the project site.

Control: With the hand tamper you hold tight charge of the entire compaction process and thus target on priority those areas that are in greater need.

Environmentally Friendly: Manual tampers do not require the use of fuel or electricity, hence they support the environment, as well as help to reduce site emissions.

Ideal for Small Projects: Hand tampers often come in handy for small-scale jobs or where space is limited and larger equipment cannot be maneuvered.

Low Maintenance: Hand tamper vs plate compactor, the hand tamper has the least number of moving parts and the minimum maintenance needed that cut downtime and repair costs.

Cons

Insights on the key cons of the hand tamper vs plate compactor are:

Labor Intensive: You need to lift and drop the tool every time you use the hand tamper thus wasting a lot of energy and time.

Time-Consuming: Wielding a tamper by hand takes more time than automatic machines like plate compactors do for the same purpose.

Limited Compaction Force: Hand tampers generate less contact force than plate compactors, so there is a chance that they may provide unsatisfactory results for concrete and similar materials of high density and thickness.

Inconsistent Results: The inside of the hand tamper often has a homogeneous pattern, which may prove difficult to compact evenly. This could cause an uneven surface and even structural problems.

Fatigue and Injury Risk: Frequent tamping with the hand tamper increases the risk of being tired and of developing repetitive strain injuries in the back and arms.

Unsuitability for Large Projects: Small-size hand tampers can only do small project compaction; the vibration is not strong enough and the work operation is slow. Tampers by hand cannot deal with the vastness of large places.

Plate Compactor

It is a device comprising of a steel or cast iron plate that compacts the asphalt, soil or gravel, etc. Plate compactor achieves this operation with the help of an engine or motor, resulting in continuous vibrations. When the plate is pressed onto the surface, it vibrates intensely to generate force and pressure then pushes the material below.

B. Working Mechanism:

The plate vibrates and moves rapidly on top of the surface to be compacted. This vibration action helps to compact and settle the material, eliminating air voids and increasing density. The machine may be powered by either a gasoline engine or an electric motor, being the source of the forces to attain desirable compaction.

C. Pros:

Notable advantages of the plate compactor are as follows:

- Efficiency: Plate compactors are powerfully productive. They can compact massive areas in a short time.

- Time-saving: Compactors make your construction projects faster with their rapid compaction speeds.

- Greater Compaction Force: The vibratory action produces maximal compaction force and creates a well-compacted material.

- Versatility: Plate compactors can be used on different surfaces and materials; hence, they are useful for various construction works.

- Reduced Physical Strain: Employing a plate compactor removes the physical labor brought by hand tamping, the traditional process.

- Uniform Compaction: The machine applies consistent and uniform compaction to the entire surface, creating a solid foundation.

- Terrains Adaptability: The plate compactors can be used for various projects thanks to their good performance on uneven or rough ground.

- Expenditures: Compared to the initial expenses, the plate compactors are the best solution to the problem of productivity improvement and labor cost reduction.

D. Drawbacks:

Insights on the key cons of the plate compactor vs hand tamper are:

- Higher Cost: Purchasing or renting plate compactors can be expensive, particularly for larger, more powerful models.

- Operator Skill: An operation on a plate compactor requires you to have some skills and training to ensure proper compaction and safety.

- Noise and Vibration: The use of this equipment often results in a lot of noise and vibrations which may be disturbing for residents or if put for a long time.

- Limited Maneuverability: The bigger the plate compactor, the harder it will be to navigate it in small confined areas like narrow spaces.

- Maintenance Requirements: The working machine is subject to periodic maintenance that takes time and money to keep it in the best possible condition.

- Weight and Transportation: Compactors can be heavy and bulky; therefore, transportation is not easy, especially for small ones.

- Environmental Impact: Gas-powered plate compactors emit exhaust gases, which form air pollution, and electric models still consume energy, although cleaner.

Comparison of Hand Tamper Vs Plate Compactor

The selection between a hand tamper vs plate compactor in your construction site depends on various factors. Let’s dive in and explore a complete analysis to help you choose the better option.

A. Performance

- Compaction Efficiency: Hand tampers produce high precision and are thus suitable for compaction in small or tight areas where plate compactors cannot be accessed. On the other hand, plate compactors are extremely effective in large open areas and can provide a more even compaction thanks to their vibrating plate. Plate compactors enable faster compaction compared to hand tampers, particularly when time is of the essence in larger projects.

- Time Required for Compaction: In hand tamper vs plate compactor comparison the hand tamper needs manual effort and thus more time for compaction, which is particularly true for large areas. Thanks to the driving motion of plate compactors, they can cover a greater area rapidly, which means faster compaction. Plate compactors are mostly used for time-critical projects where they are preferred to other choices.

B. Cost

- Initial Investment: The initial price of hand tampers is usually lower than plate compactors, which are preferred for use in small projects or occasionally. Plate compactors are endowed with motorized components; hence, they come with a higher installation cost.

- Operating Costs: Comparing the cost of hand tamper vs plate compactor. The Hand tampers’ low operational costs stem from relying solely on manual labor. However, plate compactors run on electricity or fuel, contributing to ongoing expenses. On the other hand, this efficiency saves time and labor in the longer term and can balance these costs on bigger projects.

C. Versatility

- Types of Projects: The hand tampers are for precision work on small projects, including landscape works. Due to the larger surface area, they can cover quickly. Plate compactors are appropriate for wider paving, roadworks, and foundation building.

- Terrain Adaptability: Hand tampers allow the workforce to navigate uneven areas or tight spaces where plate compactors have difficulty accessing. On the contrary, plate compactors with adjustable settings and varying plate sizes can work on different landscapes like soil, gravel, and asphalt.

D. Labor Requirement

- Skill Level: A hand tamper can be used by almost anyone and is handy because it requires only some basic skills and physical strength. Plate compactors, which are quite easy to use, certainly need some training to be managed safely and efficiently, especially if you are working with larger models.

- Manpower Needed: A hand tamp is a device that has one person working it, whereas a plate compactor may require several people for steering and refueling, mostly in bigger projects. On the contrary, the labor intensity of plate compactors can balance the extra work involved.

E. Suitable for Project Scale

- Small-scale Projects: Hand tampers distinguish themselves in smaller projects where precision and control are the main factors. They are affordable, and minimal effort is required for installation; thus, they suit small-scale DIY enthusiasts and construction teams.

- Large-scale Projects: Plate compactors are best utilized in larger projects where speed and efficiency are paramount. Their operation with motors and the ability to quickly cover large areas make them needed for commercial paving, road construction or large-scale landscaping projects.

F. Environmental Impact

Concerning hand tamper vs plate compactor for environmental impact. The Hand tampers are nearly harmless to nature as they work without fuel or electricity. Plate compactors, in turn, make noise and discharge fumes, causing air and noise pollution. Switching to electric plate compactors or responsible maintenance are ways of reducing their impact on the environment.

G. Level of Vibration/Noise

Comparing hand tamper vs plate compactor in terms of noise. The Hand tampers are quiet and not too vibrating, so they can be used in residential areas and noise-sensitive environments. Plate compactors are particularly noisy, especially gasoline-powered ones, so proper measures and attention to those living nearby must be considered.

Hand Tamper vs. Plate Compactor Products For Top Productivity

Know the top variants for hand tamper vs plate compactor in the market in the following section:

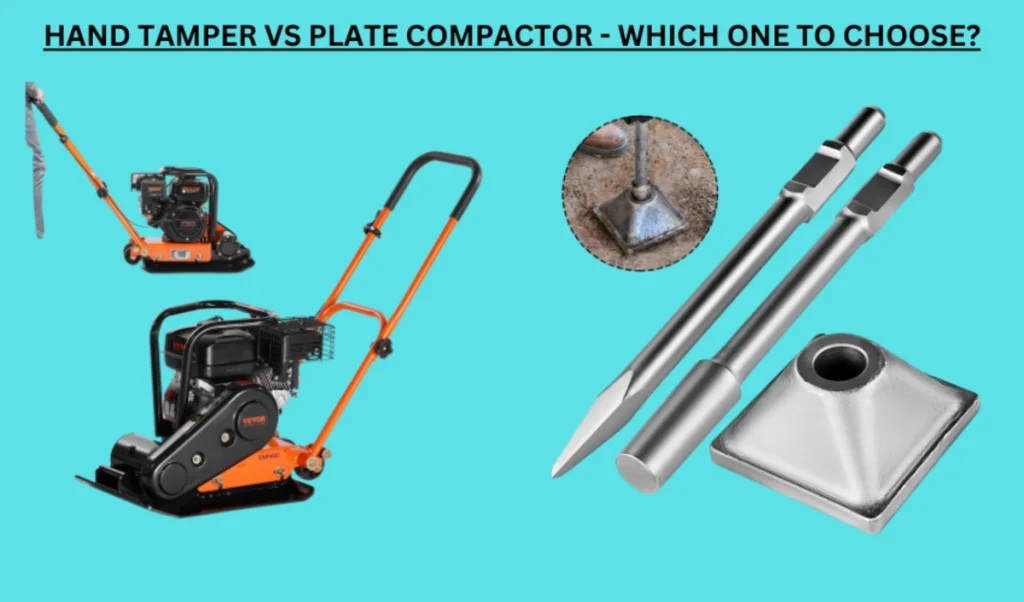

Hand Tamper

Introducing the VEVOR Jack Hammer 1-1/8″ Tamper Shank with Dirt Tamper 6×6″ Compactor Plate, equipped with Electric Chisel and Demolition Jackhammer Bits. Designed to fit all hammers with a 1-1/8″ hex shank locking system, it includes two chisels, including an extra point chisel for tackling stubborn materials. Crafted from reinforced steel, this jackhammer bit offers superior strength and wear resistance. Its solid structure ensures tight connections between the tamper shank and plate, guaranteeing stable operation. An extra-long handle measuring 16.3 inches provides enhanced comfort and ease of use. Perfect for foundation compaction and various construction tasks, this versatile tool is a must-have for your projects.

Plate Compactor

Bring your projects to life with the VEVOR Vibratory Compaction Tamper, powered by a powerful 6.5 HP, 196CC gas engine delivering 5,600 VPM and 4,200 lbs force. Its 22.1 × 15.9-inch plate guarantees efficient walkways, asphalt, and paver landscaping compactions. Our compactors come with a spacious 351 in² stamped plate and 12-inch compaction depth, which enable you to maximize productivity by covering up to 7300 ft²/h. Manoeuvre effortlessly with wide, wear-proof wheels and a sturdy 146.6 lbs design. Manage speed easily through the synergistic effects of linear throttle and choke, which amplifies performance on any terrain. Rely on this versatile compactor for a great outcome in any work, from private to municipal.

FAQs

Uncover the key and frequently asked FAQs about the “hand tamper vs plate compactor”:

Is it possible to replace a plate compactor with a tamper?

Instead of using a plate compactor, tampering is an option, but it depends on the size of your project. Hand tampers are handy in small spaces and confined areas where the plate compactor doesn’t fit. However, The plate compactor is preferable for larger projects or compaction of cohesive soils to save time and effort.

Why does the Hand Tamper/tamping rammer exist?

The main objective of a hand tamper sometimes called a tamping rammer, is to consolidate soil or gravel by hand. It is widely used for small-scale projects or difficult-to-reach areas where mechanical compactors cannot penetrate. Hand tampers offer accurate compaction in small spaces, resulting in a solid platform for construction.

What is the other name for the plate compactor?

You can also call a plate compactor a wacker, vibratory plate, compaction plate, or vibratory plate compactor. These tools use vibration to force soil or other materials to be compact and solid.

What is the purpose of the tamper?

We use tampers to compress soil, gravel, or other materials to make it firm, which is the foundation for construction. Compactors are designed to eliminate air pockets and provide dense material packing. This prevents settling in the structure, thereby ensuring structural integrity.

Which of the two is better: a hand tamper or a plate vibrator?

It depends on the particular needs of your project. Hand tampers provide high precision and great control when working in narrow areas, making them the perfect instrument for small spaces. Also, vibrating plates can eliminate more considerable regions at one time and exert less energy, thereby applying to more comprehensive projects and cohesive soils. Pick the tool that fits well into your project’s scale and conditions.

Conclusion

Finally, plate compactors will give you maximum results compared to hand tampers. Its speed and efficiency overwhelmingly outweigh hand tamper. Choose a qualitative hand tamper vs plate compactor from VEVOR and create quality projects. Boost your productivity and get better results from these handy tools. The time is now. Walk through VEVOR’s catalog to find the appropriate product for your needs. Always choose more when the best equipment is available.