With the modern age and use of ice machines, who likes to harvest the ice from mountains and frozen ponds by covering up the miles of distance? Nowadays, it’s easier to do this by pressing a button, and you’ll have tons of perfect ice cubes. But have you ever thought about how ice machines work? Using these commercial ice makers makes our lives easier and becomes an incredible part of hospitality, food services, health and fitness, education, health and horticulture, manufacturing, etc.

In commercial freezers, they’re widely used. Today, to sparkle the magic of ice makers, this article will help you to break down the process.

Exploring the Mechanism: Ice Machine Parts Diagram

Do you want to know how a commercial ice maker works? Commercial ice makers work with any refrigeration system, water supply, and way to collect ice.

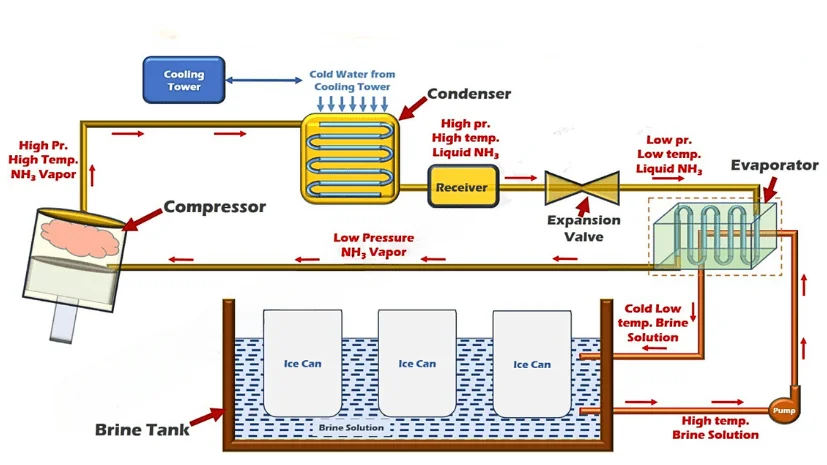

The below ice machine parts diagram and steps illustrate how portable ice makers work and give clear ice.

Compressor

Ice machines use compressors to press refrigerant to higher pressures than atmospheric pressure. Condensation happens when the refrigerant loses heat to ambient air as it travels through the coil condenser. Getting the refrigerant ready for massive expansion is important.

Cooling and Heating Ducts of Ice Makers

You can find these on the back of your refrigerator, where metal ice trays are connected with a heat-exchange pipe. During the continuous condensation-expansion cycle, a compressor circulates refrigerant fluid. A refrigerant is compressed in a narrow tube and discharged in an evaporator.

Reservoir

A chamber or container within the ice machine holds the water. It’s called a reservoir. The ice-making process relies on this source of water. As water passes over the tray during cooling, ice cubes form. After a certain period, the ice-maker activates a solenoid valve that is linked to the heat coil exchange. Refrigerant flow gets altered to turn this valve off or on. For pushing out the hot gas, the tiny condenser of the compressor is replaced with an enormous bypass tube.

Expansion Valve

Compressed liquids evaporate and expand through expansion valves, becoming gaseous. During evaporation, heat gets absorbed by the metal pipes. After this, thermal expansion quickly expands to release pressure in the refrigerant. Rapid cooling occurs when a highly pressured substance expands rapidly. Due to this, tubes and metal ice trays get cool.

The Ice-Making Process Unveiled

How long does an icemaker take to make ice? To produce a large quantity of cubes at a time, a high-quality refrigerator may take 90 minutes. However, it all depends on the features and specifications of the commercial ice makers. Most of them work on the same principle, but the following is how commercial ice-makers work.

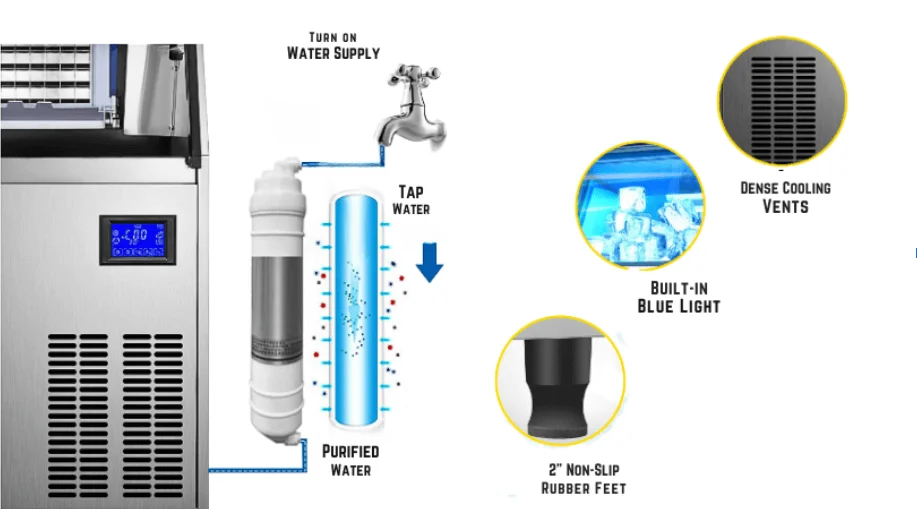

Filtration Process

The ice-making cycle automatically begins once you are on the ice-maker and connect the water source to it. Firstly, all the dust particles and impurities get removed when water goes through a filtration process. That’s how you get clean, clear, fresh ice cubes at the end of the process. Filters in ice machines need constant maintenance to work efficiently.

The compressor starts pushing refrigerant through the ice-making machine once the water goes through filtration. Heats and pressurizes gas to prepare it for rapid expansion then passes it to the condenser on the ice machine.

Ice-Machine Condenser

Copper tubes make up the condenser. These coils condense the refrigerant from vapor into liquid when it reaches the condenser. Different types of ice makers in refrigerators use different condensing units. A sequence of operations is followed by an ice machine:

- Air Cooled: By a fan, vapor is cooled into a liquid. For efficient ice-making, this type of condensation unit requires ample space.

- Remote Cooled: The condenser gets separated from the ice-maker in this type of condenser. This type of condenser operates silently but needs more maintenance.

- Water Cooled: This one has a built-in condenser, unlike other ice makers.

Pass-Through the Evaporator Processor

In the expansion valve, refrigerant undergoes rapid expansion and becomes a super-low temperature, low-pressure gas. After this, the cold refrigerant passes into the evaporator. Heat gets absorbed by the refrigerant as water flows into the tray. It lowers the temperature, and the water starts to turn into ice.

Ice Is Ready Now

The freezing point of ice makes it stick to surfaces tightly. After the ice cubes form, the compressor stops pumping refrigerant into the condenser to prevent the ice from getting stuck.

So, into the evaporator compressor, the compressor heats gas there instead of heating the tray and doesn’t lose the ice cubes. Depending on your ice machine, you can scoop out the ice manually, or your machine can dispense it in an ice bin. Until you scoop the ice, the bin keeps it cool.

Efficiency Factors in Commercial Ice Makers

How does a commercial ice maker work? For optimal performance, efficiency in commercial ice makers is crucial. Commercial ice machines are efficient due to the following factors:

Rate of Ice-Production

A high-demand environment makes ice production more efficient based on the rate per unit.

Water Efficiency

Water-saving designs, such as efficient water inlet valves, help reduce costs and energy usage.

Energy Efficiency

Modern commercial ice makers use less energy and reduce operational costs.

Cooling and Insulation Technology

Improved insulation and advanced cooling technologies reduce the number of ice production cycles, reducing energy consumption.

Water Filtration System

Integrated water filtration systems prolong the machine’s life and ensure optimum performance by preventing mineral buildup.

Self-Cleaning System

It ensures consistent performance without interruption and provides production with no downtime.

User-Friendly Design

It reduces the errors and ensures the machine performs at high efficiency.

Maintaining Peak Performance: How-To Guide

It looks like a simple process, but it’s hard to maintain your ice maker as your commercial ice machine runs this continuous process daily. So, maintenance is critical while keeping your ice machine at its high performance. Here are some tips to maintain your commercial ice-making machine.

Clean Your Ice Machine Oftenly

Ice from a dirty ice machine smells. Besides that, it’s a perfect place for bacteria and mold to grow. It’s important to clean your ice maker regularly. As well as preserving ice’s quality, it enhances your machine’s performance. Steps to clean your ice-maker through:

- Remove the ice bin after turning off the machine

- Mix 1/2 cup vinegar and water

- Soak the sponge in it and clean your bin

- Remove the vinegar smell by rinsing

- Dry the ice bin and insert it back into the machine

Replacement of Water Filter

When a water filter is dirty or clogged, it cannot function effectively. It can sometimes even cause the ice maker motor to overheat because it restricts water flow. Clean your water filter regularly, and every six months, replace them.

Examine Water Supply

Low water flow leads to low ice volume when the water supply line gets clogged. If you don’t do anything about malformed ice cubes, you will eventually experience ice maker freeze-ups. Preventive maintenance or regular inspection of the water supply line can prevent this problem.

Removing of Ice Crust

Additionally, ice makers can freeze if water continues to flow over crusted or stuck ice. Be sure to remove any crusted ice right away if you see it. Ice picks or a warm sponge can melt it away.

VEVOR Commercial Ice Makers: A Closer Look

With VEVOR one cycle, you get 132 Lbs of ice cubes. Build up with a premium water filter with crystal-clear ice cubes. Ice cubes won’t melt thanks to the six-sided cyclopentane foam layer. VEVOR offers an exceptional product that differs from other ice-makers; its heavy-duty stainless steel contributes to sturdiness, longevity, and durability. A high-end water pump ensures smooth water pumping, so the machine runs smoothly. You can now clean trays and pipes with a button, ensuring the ice cubes are odorless.

Even with this VEVOR commercial ice machine, you can adjust the ice thickness according to your needs, whether thin or thick. A widely used application allows you to use this ice-maker machine anywhere, whether in a coffee shop, hotel, bar, school, restaurant, or hospital.

But how do you use the VEVOR ice maker? Can you believe the multi-functional LCD panel allows you to operate it in various ways? Displays temperature, ice-making time, deicing test, and error messages.

FAQs about Commercial Ice Makers

Which components make up an ice machine?

The evaporator, compressor, condenser, and throttle valve are the four key components of refrigeration equipment.

When it comes to proper ice machine maintenance, what is most important?

Of course, cleaning and sanitizing contribute to the quality of ice. Neglected ice machines will develop mold, algae, and crust, which can contaminate it.

How many types of ice makers are in refrigerators?

There are two types of ice-makers in refrigerators: batch and continuous type ice-makers.

Conclusion

Within a few minutes, you get a ton of ice cubes from the commercial ice maker. Hotels and restaurants commonly use VEVOR ice maker because it produces uniform ice cubes.

VEVOR commercial ice makers are designed to deliver reliable performance while optimizing ice production and enhancing energy efficiency. While promoting sustainability and ease of use, these machines cater to the diverse needs of businesses.