Exploring the world of home improvement and tools- unravel the fascination of water chillers. They may seem unassuming devices at first glance, but their intricate working compatibility significantly impacts the longevity and performance of your favorite tools and equipment. But how does a chilled water cooling system work?

Performing a delicate ballet while maintaining the optimum temperature for smooth 3D printing, combining precision with technology. Without water chillers, your tool succumbs to wear and tear, which can end your journey as a craftsman. Furthermore, while keeping your project stand the test of time, this water chiller system enhances lifespan and cools down your tools. Let’s take a look at how a water chiller works without affecting the quality.

Table of contents

The Refrigeration Cycle Unveiled

The refrigeration cycle in water chillers is essential in removing heat from a particular substance. In contribution to how a water chiller works, here’s a step-by-step process guide of a refrigeration cycle:

- Compression

- Condensation

- Expansion

- Evaporation

- Return to Compressor

The water chiller maintains a cooling effect through these cyclic processes. By continuously repeating the condensation, compression, expansion, and evaporation process, they efficiently remove the heat from the desired substance and space while ensuring a comfy environment.

Key Components in Action

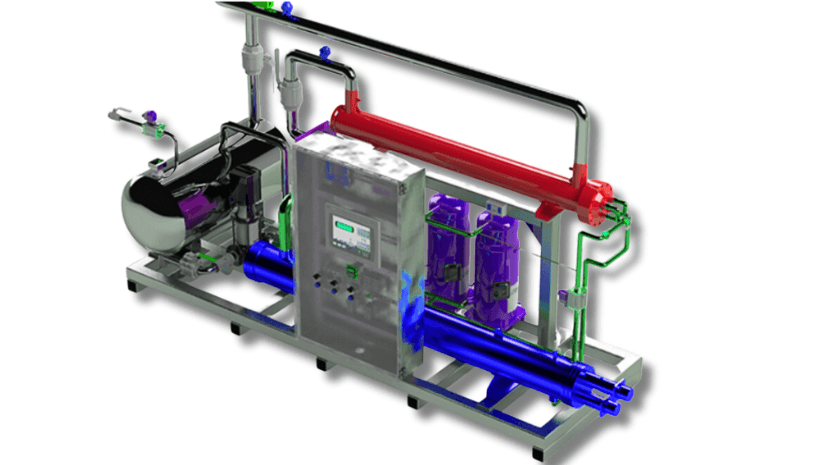

How does a water chiller work? Several major components work together to achieve the maximum result. For those who don’t know how a water chiller works, this article turns out to be a great detailed guide. So, let’s explore each of the components that are involved in the water chiller working process.

Compressor

A crucial component through which the refrigeration cycle is initiated. Increasing the temperature and pressure compresses the refrigerant vapor and low pressure. So, it allows the refrigerant to release heat during the condensation phase.

Condenser

During the compression phase, the condenser releases the heat, which the refrigerant absorbs. This process helps the refrigerator go from high vapor to high liquid pressure. To the external environment, heat is expelled, and the refrigerant turns from a gaseous state to a liquid state.

Expansion

An expansion flow controls the high-pressure liquid into the evaporator. Due to this, it causes a sudden drop in pressure and temperature. As a result of this expansion, the refrigerant becomes a liquid mixture and vapor and prepares it for evaporation.

Evaporator

However, the evaporator then absorbs the heat from the surroundings, causing it to evaporate. Due to this process, cooling takes place. The refrigerant transforms a liquid into a vapor by absorbing heat from space. By this endothermic process, a cooling effect is created.

Refrigerant

The refrigerant passes through phase changes during the refrigeration cycle. Additionally, it absorbs and releases heat alternately. It transfers heat through the main components like condensers, compression, evaporators, and expansion valves.

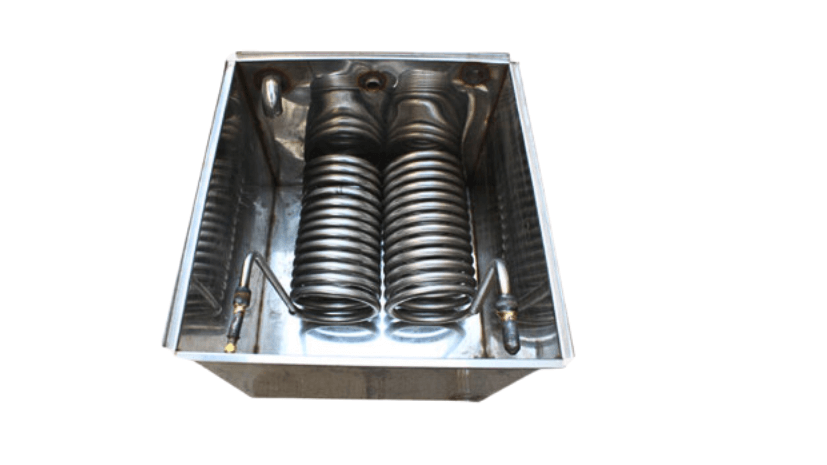

Coil Condenser

A condenser coil is the heat exchanger in the condenser unit. Heat is transferred from the high-pressure refrigerant to the surrounding air or water. In a condenser coil, heat dissipation allows the refrigerant to undergo a changing phase and release the heat.

Evaporator Coil

A heat exchanger is situated in the indoor unit or the space. A low-pressure refrigerant absorbs the heat from the surroundings. Heat is absorbed through the evaporator coil, allowing the refrigerant to evaporate and cool the air and surrounding area.

These components work together to transfer heat from the interior to the exterior while maintaining a controlled and comfy temperature. Additionally, the components such as a circulated pump, water-cooled condenser, and control system are installed to enhance the adaptability and efficiency of application needs.

Evaporators: Transforming Heat into Cold

In the refrigeration cycle, evaporators play a vital role by absorbing heat from the water or letting the substances cool. But how does a chilled water cooling system work? This process is achieved through water chillers. Here’s a detailed overview of how evaporators accomplish this task.

Design: The design of the evaporators facilitates the transfer of heat between the refrigerants and allows the substance to be cooled. These usually consist of tubes or coils through which refrigerant flows.

Contact with Substance: It gets cool due to the direct contact with water and substances. At the evaporator coil, heat transfer occurs, facilitates safer occurs, and facilitates thermal energy exchange between the water and refrigerant.

Endothermic Process: The process in the evaporator is known as endothermic and allows the heat to be absorbed from water. For various applications, this heat absorption is crucial for cooling, likely in industrial and air conditioning processes.

Water Cooling: The water temperature decreases when the refrigerant extracts heat. This cool water is then transferred to the desired location for industrial processes, air conditioning, or other cooling applications.

These processes contribute to the operation of water chillers and are necessary for maintaining temperature control in different applications.

Condensers: Releasing Heat to the Environment

Condensation is when the refrigerant releases the heat and goes through a phase change from vapor to liquid. That’s how the chilled water system works. Let’s take a look at the cooling process that takes place during the condensation stage:

High-Pressure Vapor: The refrigerant is in a high-pressure and temperature-vapor state after leaving the compressor. During the heat absorption, the evaporation stage releases the heat to the surroundings.

Condenser Coil: A high-pressure temperature flows into a condenser coil in the outdoor unit. Through these coils, heat exchange occurs with the ambient water or air.

Vapor to Liquid Phase: In the condenser, heat release means the refrigerant loses energy. As a result, it converts from a high-vapor pressure to a high-liquid pressure.

Heat Dissipation: Heat dissipation ensures the refrigerant undergoes the phase change from vapor to liquid, allowing the evaporator to expand and cool.

Liquid Exiting the Condenser: After releasing heat and condensing into a liquid state, the refrigerant exits the condenser and prepares for the expansion valve. For the next refrigeration cycle, it’s now a high-pressure and temperature liquid.

Compressors: Boosting Refrigerant Power

Compressors facilitate vital compression and heat transfer. Take a look at compressors’ significance in overall efficiency:

Initiate Refrigerate Cycle: Compressors are liable for low-pressure compressing, and from the evaporator, low temperature vaporizes, allowing heat to be absorbed, transferred, and released.

Increase Temperature and Pressure: The main function of the compressor is to raise the pressure and temperature of the refrigerant. While compressing vapor, the compressor increases the energy of the refrigerant and prepares it for condenser heat release.

Heat Exchange Efficiency: The compressor efficiency affects the whole refrigerant system. A great design and function promotes heat exchange and cooling in the condenser and evaporator.

Advancement In Technology: Technology advancement in compressors improved efficiency and contributed to the energy savings like screws, speed compressors, and variables. In multiple applications, these innovations boost the overall performance.

Types of Water Chillers

There are various types of water chillers, and each water chiller system is designed to meet specific needs. But it’s crucial to know how a water chiller works. They’re buying based on different factors such as environmental conditions, temperature requirements, and cooling load. The following are the different types of water chillers and their specific applications:

Absorption Chillers

- Combine heat and power system

- Recover waste heat from industrial process

- Facilitate cheap heat sources

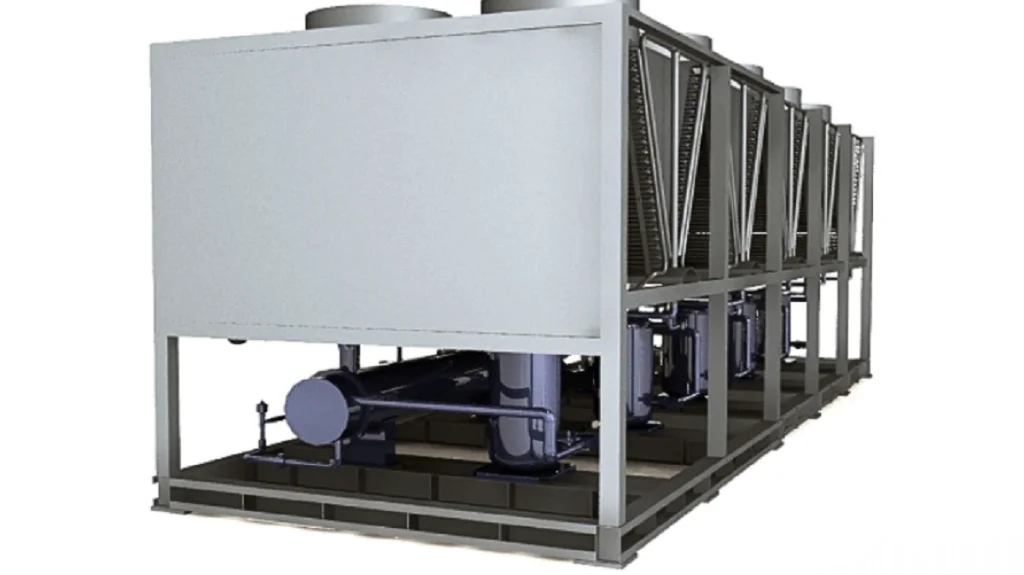

Air Cooled Chillers

- For commercial and residential HVAC system

- Water limited industries

- Outdoor cooling system

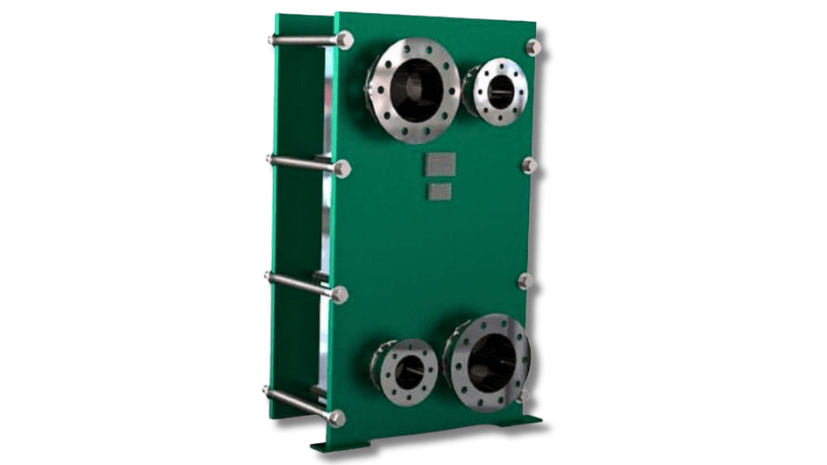

Water Cooled Chillers

- High cooling load industries

- Commercial buildings with large HVAC systems

- Water-friendly sources

Centrifugal Chillers

- High load buildings

- Facilitate the tough and demanding cooling industries

- Complex cooling applications

Scroll Chillers

- Use in laboratories

- Medium size commercial buildings

- For server rooms, air conditioners

Reciprocating Chillers

- For the cooling process in manufacturing

- Small commercial buildings

- Educational institutes

Screw Chillers

- Large industries

- District cooling system

- Large commercial buildings

Portable Chillers

- Cooling spots in manufacturing

- Equipment failure in cooling

- For events and projects

Condenser Type

According to condenser type, water-chillers come in two different types of air: cooled and water-cooled:

Water Cooled Water Chillers

How does the water chiller work, and where do you use it? Water chillers use water as the condensing medium. As their cooling medium, these chillers use water and consist of two water loops in the system. These chillers operate with a cooling tower. The cooling tower produces cooling by bringing air and water into contact instead of the conduction-convection type. This is done by supplying cooling water to the condenser unit, which helps cool the refrigerant. Water chillers are used in enormous industries where cooling water is available. High-efficiency cooling is provided compared to the air-cooled types.

Air Cooled Water Chillers

The air-cooled chillers exchange heat between the refrigerant and the air. As a condensing medium, they use air. So, following this process, that is how water chillers work. These chillers feature finned coils, increasing the condenser surface area to contact with air. Multiple fans can blow the air over the coil for further heat transfer. A condenser removes heat depending on the fast air flows over the coils and the warm air. The great advantage of using air-cooled water chillers is their lowest cost. Without requiring additional infrastructure, they can be installed easily.

Conclusion

This brief guide will be helpful if you don’t know how a water chiller works. All the chillers work similarly, but it depends on how they release heat in the environment. Compressors are bought based on their cooling and loading capacity. Due to their efficient operation, VEVOR water chillers stand out in the crowd. From basic daily needs to industrial ones, VEVOR has all that you need. You’re just one click away, so browse, buy, and get products at discounted rates.