When there was no technology, people believed in the paradoxical metalworking methods. Anvils have been the most popular tools for preparing metallic objects, shaping materials, and converting jewelry from one shape to another. Guess what? They are still reigning in the industry even after centuries due to their endless benefits, smooth work, and lower maintenance.

When thinking about the anvils, the first question is: how much does an anvil weigh? Is it reasonable to have a lightweight anvil or a heavyweight? The general rule is fifty times heavier anvil compared to the hammer. For instance, if you have 1kg of hammer, the anvil must be 50-60 kilogram. However, you still need to measure the goals and metalpiece aspects.

Different factors are game-changers for the anvil weight, size, and choice. Do you want to know them all? In this guide, we have illuminated all the anvil weight aspects with various tips on choosing the best anvil.

Table of contents

What is an Anvil?

Anvil is a unique metalworking tool with at least one flat surface. It is usually forged or cast steel. High inertia pushes the hammer back and rebounds the force, leading to efficient results for your metal shaping, shoeing, or smoothing.

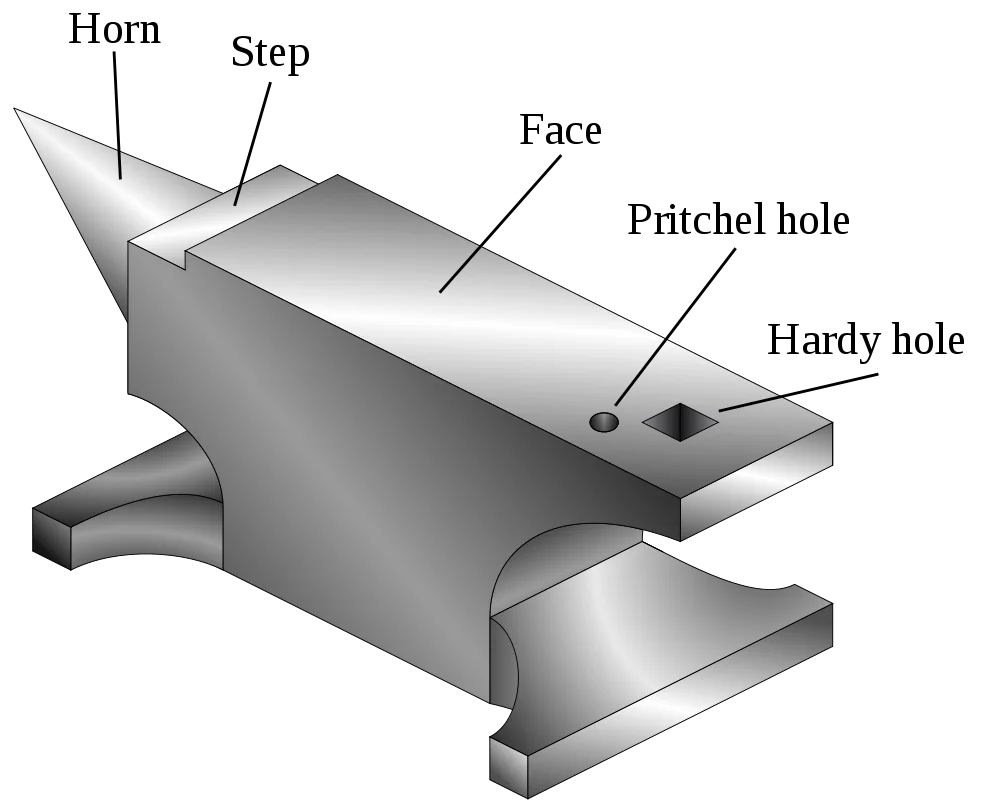

There are different parts of an anvil.

- Face

- Pritchel hole

- Hardie Hole

- Step

- Heel

- Body

- Waist

- Foot

Types of an anvil

Anvil weight and size depend on the purpose. Based on the shape, the anvil comes in three fundamental options.

- Anvil with horns

- Cutlers Anvil

- ASO or anvil-shaped objects

Uses of Anvil

Anvil turns out to be a gold in the right expert’s hand. It involves the following applications.

- It helps shape the metal into multiple structures based on the needs.

- You can smoothen the edges of different metals and enjoy a better view.

- It is suitable for forging purposes such as shrinking, bending, and forge welding.

- Sometimes, it is also a part of the jewelry industry to shape the gold and silver objects.

How Much Does an Anvil Weigh?

An anvil weight is in between 75 pounds to 500 pounds. Such a weight is useful for forging and metalworking applications.

Moreover, anvil weight and size calculation is quite crucial. You can estimate the weight in the following ways.

For example:

- CWT system that is often popular in the UK

- Pounds of the weight

- The standard SI unit of weight is the kilogram.

Let’s evaluate anvil weight parameters one by one.

Weight assessment via markings

Some anvils have specific markings on their body areas. These are pretty matchable with the total anvil weight and size. American anvils have the weight marked in the pounds. Some European brands also cause the pound weight markings.

If you still can’t guess the right weight, do the simple thing. Weigh it and compare your guess with the correct size. You’ll get the idea of weight in pounds or kilograms.

Weight assessment with Hundreds Weight system

The Hundredweight system is a good idea for some anvil weight assessment. This is the system that helps define the weight.

The first figure shows the 100-pound count in the US hundredweight system and the 112-pound in the UK hundredweight system.

The second figure shows 28 pounds. And the third one is the actual pounds to be added.

For instance:

1.1.2 = 1 x 100 + 1 x 28 + 2= 130 pounds in the US hundredweight system is the anvil weight

1.1.2= 1 x 112 + 1x 28 + 2= 142 pounds in the UK hundredweight system

A dot separates every single digit.

Weight in kilograms and pounds

Most users remain confused between pounds and kilograms. A pound is a customarily used jnit globally in the major countries. On the other hand, the kilogram is an SI unit.

1 kilogram = 2.205 pounds

Let’s make a rough calculation by converting the kilogram into the pounds. A 60-kilogram anvil will have an average weight of 132 pounds. You can calculate the opposite by dividing the pounds by 2.205 and getting the weight in kilograms.

Selecting an Anvil: Which Is Right for You?

A right choice with the right anvil weight and size can be your partner for life. We have evaluated the following factors to know for your anvil.

Anvil weight calculator: choose the size

How much does an anvil weigh? That pops out at the first glance.

The first thing about selecting the VEVOR anvil is its size. It also defines the robustness of the anvil. Since it is used for metal bending and shaping, predict the use of heavyweight anvils.

Typically, for 1 kilogram of hammer size, you need 50 times more weight to occupy the anvil. For example, if your hammer size is 2 kilograms, purchase an anvil weighing at least 120 kilograms.

But it depends on the type of applications and purposes. The table shows the different purposes with their required anvil weights.

| Type by Weight Range – Min. – Max. | ||

| Pounds | Type | Kilos |

| 75 – 500 | Forging | 35 – 230 |

| 50 – 150 | Farrier | 23 – 70 |

| 5 – 100 | Stake | 2.3 – 45 |

| 5 – 50 | Bench | 2.3 – 23 |

| 0.3 – 5 | Jewelers | 0.14 – 2.3 |

If you are using the anvil for the forging, consider the higher weight. 75 pounds is the lower limit. You can go up as long as you are following the rule of hammer size to the anvil weight ratio.

Based on your needs, you can modify the anvil weight and find a compatible anvil.

New or used?

In the next step, you must ponder the new and used.

New anvil

It is a brand-new anvil that offers a long life and several uses. There are no scratch marks or other issues compared to the used anvils. However, there is one problem with it— high costs. If you are a pro blacksmith, this can be the right choice with a long-lasting strength.

Used anvil

Used anvils are second-hand pieces with scratch marks and signs of wear and tear. It has various advantages regarding lower costs, suitability, and ultimate strength. Plus, it can be an excellent piece to try if you have started your career as a blacksmith.

Which one to choose?

It can be an easy choice if you have plans on a more durable option and have a decent budget: go for the new anvils. If you are trying metalworking for the first time, used ones can be a good partner.

Material

Anvils are made up of different materials. These include:

- Cast iron. It is an inexpensive yet durable metal. But you can’t expect a long life compared to steel materials.

- Steel. Steel anvils have good strength and wear and tear resistance compared to cast iron. They are more expensive than cast iron and offer extended support without deformation in shapes.

- Tool steel. They are one step better than steel material in strength, hardness, and durability. Even the price is higher.

- Cast Steel. These are the most popular and expensive anvils, famous for their durability. Strong wear and tear resistance offers you a good lifespan.

- Hardened steel. In actuality, it is a low-carbon steel material. Due to its extended durability, it is pretty popular.

- Wrought iron. Such anvils have a robust structure and exceptional hardness, leading to a longer life.

If you want a good quality anvil with a long life, steel is a good option. For meager budgets, think about the iron. For higher budgets, stand with the cast steel and enjoy years of non-stop metalwork.

Other factors to consider

Budget

Don’t buy an expensive anvil. Measure the budget and hunt down the best quality anvil yet at the affordable costs.

Usage frequency

Typically, an anvil lasts 25 uses. A more durable anvil offers more uses and ensures a long life. Based on usage frequency, you can get the best anvil for work.

Usage scenarios

For forging, you should get a more robust material such as cast steel. Think about different other factors too for better results.

Portability

The shape of the anvil should be compact and easy to transport from one place to another. Also, consider the weight to reduce the shipping expenses.

VEVOR Anvil: Durable and Robust Metalworking Tool

VEVOR anvils have been popular for their quality and cost. Pocket the best anvil yet at an affordable. It is a profitable deal. Even VEVOR anvil reviews can guide you better about its use and metalworking processes.

So, you get all the features in one place. Let’s talk about the VEVOR anvil features and their pros.

- High-grade steel material. VEVOR uses the drop-forged high-grade steel of 50 HRC that adds strength to its products.

- Round and flat horn. Get dual horns for practical forging, shaping, and bending of materials.

- Polishing treatment. VEVOR offers the polishing treatment for protection against corrosion.

- Versatility. Handle all the applications of riveting, flattening, forging, and forming metal.

Pros of VEVOR anvils include:

- Sturdy Design. Enjoy the next-level forging experience with the sturdy base of your VEVOR anvils. These offer more stability during work and ensure the highest efficiency.

- Durability. VEVOR anvils are not going anywhere soon, thanks to its cast steel construction that allows a long life. Plus, quality control during manufacturing bestows a longer lifespan.

- Reduced Costs. There is no need to empty up your pockets when VEVOR is here. Get the anvils at affordable costs and enjoy the best work efficiency.

- Numerous features. From a long life to multiple uses, VEVOR anvils have high inertia and provide many supporting features for your metalwork.

Maintaining and Caring for Anvils

Undoubtedly, anvils are robust tools with high durability. But it is still necessary to prolong their lives.

How will you do that? Simple. Manage them in the following ways.

Keep It Clean

Cleaning and maintenance are essential. Detect the dust and debris. Eliminate it on time to avoid future issues. Use the cloth to remove the micro pieces of the workpiece with the fabric.

Prevent Rust

Cast steel is not very prone to rust. Moreover, the polishing of the anvil keeps the rust miles away. Think about every possible way to prevent rusting.

Check for Cracks

Are there any cracks visible? If yes, repair it immediately. Manage over time and go for the microcracks inspection. Keep it preserved when not in use.

Store Properly

Always follow the manufacturer’s instructions for the storage. Usually, a room temperature is a good idea. Avoid keeping it at extremes of temperature, whether warm or cold.

FAQs about Anvil Weigh

How big is a 100 lb anvil?

Anvil size is quite crucial when making a purchase. Usually, a 100-pound anvil has a size Face (12-5/8″ x 4″) with a Base (9″ x 8-3/4″) and an Overall Length is 23-3/4″. If you want to know the weight of a 100 lb anvil in kilograms, it is 45 kilograms.

Why are anvils so heavy?

Anvils are pretty heavy due to their construction of cast iron or steel. Moreover, the goal is forging the metal, so it is customary to use heavy anvils for high work efficiency.

How do you tell the weight of an anvil?

A few methods can help you know the exact weight of your anvil.

- Markings on the anvil.

- Hundredweight system

- Manufacturer’s product detail guide

- Manual measurement of weight

You can also ask the manufacturer regarding the weight of your anvil.

What is an anvil worth?

Finding an anvil cost is sometimes significant when you have a limited budget. Therefore, a new anvil can cost $6-$9 per pound, while used ones are available at $3-$6 per pound—a 50-pound anvil costs anywhere between $300-$450. However, VEVOR offers a 66-pound anvil at just $146.

How can you tell a good anvil?

A good anvil means the right size and quality constructions. 50kg anvil size with cast steel construction is the best size you can purchase at the next stop.

Conclusion

Right anvil weight is necessary. For example, a 30 pound is of no use for the forging. While a 30-pound anvil is more than required for the jewelers. The right choice with the accurate anvil weight must be your first choice. Also, keep an eye on the excellent quality anvil.

One of the top anvil brands is VEVOR, the perfect spot for quality at affordable prices. Why do you even wander when you have all the anvil solutions in one place? Enjoy the right tool with a diversity of weight options. Check out the best VEVOR anvils right away!