Attaching a socket to a drill increases its capacity for many applications. Usage of sockets in drill is common in many different types of DIY projects, from professional building work to recreational usage such as installation of shelves. Since this attachment can enhance and improve your projects, it’s essential to have the technical know-how of how to properly attach a socket to your drill.

It’s also important to mention that the quality of your socket set has a huge role to play in the success of your various projects. For professionals, DIY experts and home decor enthusiasts who are in the market for a quality socket set, we recommend the VEVOR impact socket set. The VEVOR multipurpose impact socket is made from superior Cr-V impact-grade alloy steel which qualifies it for a broad spectrum of operating conditions. The sockets’ design lowers wear and prevents bolts from peeling and rounding. And these high-quality sockets conveniently come in a metal toolbox that is lightweight and portable.

Keep reading to understand the basics of drills and sockets so you can learn how to properly attach your socket to a drill.

Table of contents

Understanding the Basics of Drills and Sockets

There is a wide range of drills and sockets each specifically tailored for different materials and purposes. For instance, many drills are specifically designed for softwoods, while some sockets are made for tight spaces. Let’s get into them.

What is a Drill and How Does it Work?

Drills are mechanical instruments that use a cutting or drilling tool that spins on a fulcrum to bore holes into wood, metal, plastic and other materials. You can use these holes to attach studs, screws, nails, and other hardware to a wide variety of surfaces.

Drills often come in different types such as:

- Cordless drills: Rechargeable drills that operate wirelessly.

- Impact driver: For driving screws and other fasteners.

- Corded drills: Electrically linked with wires.

What is a Socket and Its Uses?

A socket is an adaptable and practical tool that, when used properly, allows its user to work with fasteners of many sizes and kinds, most often nuts and bolts. Typically, it is packaged in a set of sockets in one convenient container, box, or bag. The primary function of a socket is to tighten or loosen fasteners. The following are the types of sockets:

- Impact socket (For power tools such as electric and pneumatic air wrenches).

- Imperial socket (For fasteners with heads measured in inches and fractions of inches)

- Deep socket (For hard-to-reach places and tight spaces)

- Hex socket (6-point socket)

- 12-point socket ( Bi-hex socket)

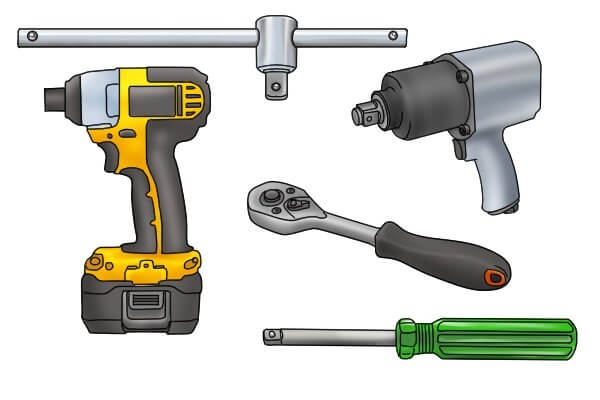

Tools Needed to Attach a Socket to a Drill

As you prepare to learn how to attach socket to drill, this section uncovers essential tools required to attach a socket to a drill for efficient and versatile use in various tasks. Meanwhile, we recommend the VEVOR impact socket for a durable and effective usage.

Essential Tools and Equipments

- Drill: Provides power to drive the socket.

- Socket Adapter: Connects the socket to the drill, converting the drill’s chuck to fit the socket.

- Socket Set: Contains various sizes to fit different bolts and nuts.

- Screwdriver: For tightening or loosening screws

- Safety Gear: Includes gloves and safety glasses to protect hands and eyes

Introducing the VEVOR Impact Socket Set

The VEVOR impact socket sets are made from premium Cr-V impact-grade alloy steel, which greatly improves its resistance to and absorption of impacts. It is an excellent choice for many operating settings. The impact driver socket set is produced with carefully laser-etched and rolled size indications to make it easy to identify socket sizes, especially in low light.

Apart from the high-quality materials used in manufacturing the tool, the following are other features and benefits of VEVOR impact socket that make it a preferred option for DIYers, auto mechanics, and other handymen:

- It is versatile, a quality that makes it work well in a wide variety of operational contexts.

- The hexagonal drive’s design makes the socket set ideal for reducing impact pressure on fasteners.

- The design of the sockets prevents bolts from rounding and peeling and reduces wear. It also distinguishes it from conventional designs without rounded corners.

- Unlike standard one-piece storage, the split-strengthened case is sturdy and won’t break easily. It is also portable due to its lightweight and compact design.

Recommended For Your Project

Step-by-Step Guide on How to Attach a Socket to a Drill

Follow our step-by-step guide on how to put socket on drill, using a drill, socket adapter, socket set, screwdriver, and safety gear for a secure and efficient setup.

Preparing Your Drill and Socket

- Get the correct socket adapter while getting the drill ready. The drill and the socket set you want to use must be compatible for the adapter to be used.

- Make sure the adapter’s dimensions and form are a good match for your drill’s chuck.

- The next thing to do is check the drill chuck for dirt and debris so you can clean it.

- A little lubricating oil could help loosen a tight drill chuck and make it easier to spin.

- Properly tighten the socket adapter after inserting it into the drill’s chuck.

- Tighten the chuck using a screwdriver or your hand. Be careful to hold the adaptor securely in place.

Attaching the Socket to the Drill

- Before attaching socket to drill, make sure your drill is off and disconnected.

- Be cautious not to injure yourself by not firmly fastening the socket to the drill once you’ve chosen the right socket size for your drill.

- Locate the drill’s chuck. The drill’s chuck is where the socket is stored.

- Quickly attach the socket to the chuck while ensuring it is the correct alignment.

- Tighten the chuck position to keep it in place. You may do this by hand-turning the chuck clockwise or, if your drill is equipped with one, by using a chuck key.

- To ensure the socket is firmly fastened after locking in the chuck, gently pull on it. It shouldn’t be easy to remove.

Testing the Attachment

- After you attach socket to drill, verify the socket’s alignment with the drill and the tightness and security of the connection.

- Inspect the link for indications of wear and tear that might weaken it.

- Take a tight hold of the drill and the socket that comes with it. To loosen or turn the socket, gently push down on it. A socket that is securely fastened shouldn’t budge or fall off.

- Start the drill and set it to a low speed to check the connection further. Listen for strange noises, sensations, or motions. If none, the connection is solid.

- Last but not least, inspect the drill for any safety features or systems. Verify that all safety switches and guards are in good working order.

Common Uses for a Socket Attached to a Drill

We explore the common uses for a socket attached to a drill in this section. This includes automotive repairs, furniture assembly, and various DIY projects, for increased efficiency and convenience.

Practical Applications in DIY Projects

Sockets on a drill can be used for several home improvement projects such as constructing custom furniture, tables, garden beds, and other DIY projects with ease. It also speeds up the process of assembling furniture from manufacturers and can be used to quickly disassemble furniture for moving or storage. Not only that, you can use the drill to securely fasten heavy-duty shelves to walls.

Professional Applications

Professionals use sockets attached to drill for automotive applications such as removing and replacing lug nuts on car tires. They can be used to fasten or loosen bolts in hard-to-reach areas of the engine compartment and easily remove and install car parts during routine maintenance.

Not just that, professionals use them to drive large fasteners and bolts in construction projects, such as framing and scaffolding. They are also used to secure electrical panels and conduit with appropriate fasteners. They are also effective for tightening large electrical connectors and terminals.

Tips and Tricks for Efficient Use

Drills are multipurpose tools that have many uses, from drilling holes in wood to assembling furniture. Hence, it is important to use drills properly since they can be dangerous if handled carelessly. Check out these safety tips for using your drills efficiently.

Best Practices for Using Sockets with Drills

- Keep your drill and socket in a dry, clean place at all times. Make sure to shield them from direct sunshine, very hot temperatures, and dampness.

- To keep the socket and drill in pristine condition, wipe them off with a damp cloth or brush after each use.

- Maintain a well-oiled tool set to keep them in top condition for much longer.

- Check the socket and drill for damage, wear, and loose components on a regular basis.

- Tighten any screws or bolts that are loose for efficiency.

Safety Tips to Keep in Mind

- Before using a drill, use a protective eyewear

- You risk hurting yourself or someone else if you grip the drill too firmly. Make sure you hold the drill firmly yet softly with both hands instead. It’s a great way to practice relaxing.

- Check the socket for chips, cracks, or other damage before you connect it to the drill.

- Always switch off and unplug the drill before adding or removing a socket.

- Always use a drill in a well-ventilated environment to avoid breathing in dust or fumes.

FAQs About Attaching Sockets to Drills

Find answers to repeatedly asked questions about attaching sockets to drills, including those related to compatibility, tools required, common uses, and safety tips for efficient and safe operation.

Can a socket be attached to any drill?

No! Not all drills are compatible with sockets. A square drive on the drill must correspond to a square drive on the socket. So, before you try to connect the socket and drill, make sure their square drives are compatible.

How to determine the appropriate correct size?

If you want to use the correct socket size for a bolt or nut, measure it beforehand. Pick a socket that is almost a perfect fit for the nut or bolt diameter. To prevent denting or defacing the fastener, it is best to err on the side of caution and go somewhat bigger rather than smaller.

What can I do if the socket does not fit into the drill?

To fix a socket that won’t click into the drill, check that the square drives of the two tools are lined up correctly. If the square drive on the drill is broken or worn, you should probably get a new one or have it fixed.

Conclusion

Mastering how to connect a socket to a drill opens up a world of possibilities for DIY projects, automotive applications, and more. However, do not forget to heed attentively to the safety tips when using sockets on drills so you can get the job done safely, efficiently, and flawlessly.

We are also aware it is difficult to narrow down the options to choose a socket set that would best suit your needs when there is such a wide variety of sizes and models available. Out of the many available options, we recommend the VEVOR impact socket set. You should visit the VEVOR store to buy this effective socket set, and you can go ahead to follow our tips on “how to put socket on impact wrench” to enhance the productivity of your various projects.