Forks are tools used for moving things around on farms, construction sites and factories. They make your tractor bucket more useful by helping you lift items, with ease, such as pallets, hay bales and boxes. Moreover, they provide even weight distribution, making them secure to carry heavy loads.

You can conveniently load and unload materials and stack objects, facilitating material handling. Installing forks to a tractor bucket is a cost option since you won’t need to buy equipment. This makes them a smart investment, for farmers and companies looking to streamline their activities and increase efficiency.

However, you should know about the installation procedure to ensure the operations are safe. It also transforms your tractor bucket to accomplish transportation tasks more efficiently. In this blog post, you’ll explore how to install forks on your tractor bucket. You’ll also discover the kinds of attachments that can be added to tractor buckets and ways to address any problems. So let’s dive in.

Table of contents

Types of Forks for Tractor Buckets

Not all types of forks are suitable for installation on a tractor bucket. Here are the types of forks you can use to upgrade your tractor bucket:

Pallet Forks

Pallet forks consist of two prolonged sturdy metal bards or tubes. They are typically 36 to 48 inches long and can be attached to a tractor bucket or skid steer. They are designed to maneuver materials and heavy loads placed on pallets conveniently. Some materials can also be loaded directly on pallet forks.

This type of fork offers exceptional efficiency and helps boost productivity. Pallet forks make lifting and transportation hassle-free and secure. The variation in their sizes allows you to pick one according to your needs and budget. Moreover, you can customize these forks for multiple applications.

Bale Spears

Bale spears are long, pointed tines made of high-strength metals. They are useful agricultural attachments. It is meant to handle vast bales of straw or hay. These sturdy tools assist farmers in transporting bales with minimum labor. They are adaptable to various machinery setups, including tractor buckets, three-point hitch systems, and skid steers.

Grapple Forks

Grapple forks are another versatile tool for convenient transportation in agriculture, industry, forestry, and construction. Attaching them to a tractor bucket can help you lift logs, rocks, brush, and debris. Hydraulic cylinders power grapple forks. Their hydraulic system and unique design offer a secure grip for maneuvering irregularly shaped items.

Customized Forks for Specific Applications

Customized forks are a great innovation that caters to the unique requirements of various industries. You can modify the existing features or equip them with advanced tools to optimize their performance. For example, you can customize fork length, capacity, and spacing to make them suitable for lifting and lowering particular objects. Customized forks are more efficient as they are properly configured.

Choosing VEVOR Pallet Forks For Your Tractor Bucket

Choosing the right fork for your tractor bucket is necessary to maximize its efficiency and durability. Today, the market is saturated with various suppliers offering forks in different styles, sizes, and capacities for installation on your tractor bucket.

VEVOR is one of the best pallet fork suppliers. It offers a vast range of pallet forks to help you choose one that fits your needs.

2000 Lb VEVOR Pallet Fork

Upgrade your farm equipment to VEVOR pallet forks with a lifting capacity of 2000 lbs. Assembled from the tough squared steel tubing, these forks ensure durability, resisting bending and breaking. Reinforced bolts and grooved screws head designed to ensure durability. Very easily add them to your tractor, skid steer, or loader bucket for multi-function operation. It is easy to install – just slide the fork over the cutting edge of the bucket and tighten firmly. Great for moving logs, wood, firewood, and also fence posts, hay bales, and other debris clearing tasks. Dimensions: 43″ overall length, 30″ fork blade, 2″ height, 2.75″ width, and 2.95″ gap between the bucket lip and the blade. The package consists of 2 forks and 1 user manual. Now is the time to ramp up your farming!

4000 Lb VEVOR Pallet Fork

Upgrade your tractor with the VEVOR pallet fork, have a 4000 lbs capacity and durable. These are made out of square steel tubing that is difficult to bend and break. They are a durable choice for your daily assignments or projects. The combination of reinforced bolts and grooved screw heads ensures that performance will be long-lived. Adjust the stabilizer bar easily by switching it between 19.5″ and 36″ to secure heavy loads, thereby ensuring safety during farming and gardening activities. Installation is a piece of cake – just slide over the bucket cutting edge and clamp it down. Multipurpose and speedy, move logs, wood, hay bales, and more effortlessly. Package contains a fork, a stabilizer bar, and a user manual. Increase your productivity with this must-have attachment.

Furthermore, get insights on Top 4 Compact Tractor Pallet Forks for Efficient Heavy Lifting.

Besides pallet forks, VEVOR offers a huge range of several other tools. You can find all agricultural and forestry equipment at the best rates. All the tools VEVOR lists are premium-quality and affordable. So, get the tool you need from VEVOR and streamline your operations.

How to Install Forks on Your Tractor Bucket

Learning how to install forks on your tractor bucket is not a difficult task. However, you can’t get the best results without knowing the ins and outs of each step. Here are the steps involved in installing forks on a tractor bucket:

Tools and Materials Required

Before you start the installation make sure you have all the tools and materials on hand. Having the tools and materials is just as crucial as the installation itself. This will help you save time and ensure an easy process. Here are the tools and materials you need to gather to install forks on your tractor bucket:

List of Tools Required for Installation

The following is a list of tools required for a smooth installation of pallet forks on a tractor bucket:

- Wrench set

- Nuts

- Screw rods

- Screws

- Socket set

Necessary Materials and Their Specifications

The following are the materials you should have to install forks properly:

- Get durable forks from a reputable supplier. The quality of forks is crucial to lifting heavy loads and rough usage. However, the forks you pick should be compatible with your tractor bucket. Consider the forks’ length, width, and load capacity to ensure they are compatible with your intended use.

- Stabilizer bars are placed between the two forks. They offer stability while lifting and lowering any load. Your stabilizers should be sturdy enough to support the forks while lifting heavy loads.

- You also need chains to wrap around the bucket. They improve the stability of the forks. They should also be solid to prevent the bending of forks during operation.

- Chain binders secure the chains, preventing chains from moving while lifting any object.

Installation Procedure

Proper installation of forks on a tractor bucket significantly impacts its functionality. Let’s understand how to install forks on your tractor bucket:

A. Gather all the required accessories

Before the installation of forks, collect all the required accessories. This includes, but not limited to, the forks, nuts, screw rods, connecting rods, and tools mentioned above necessary for assembling. It is essential to have everything available to easily and efficiently install it without any interruptions.

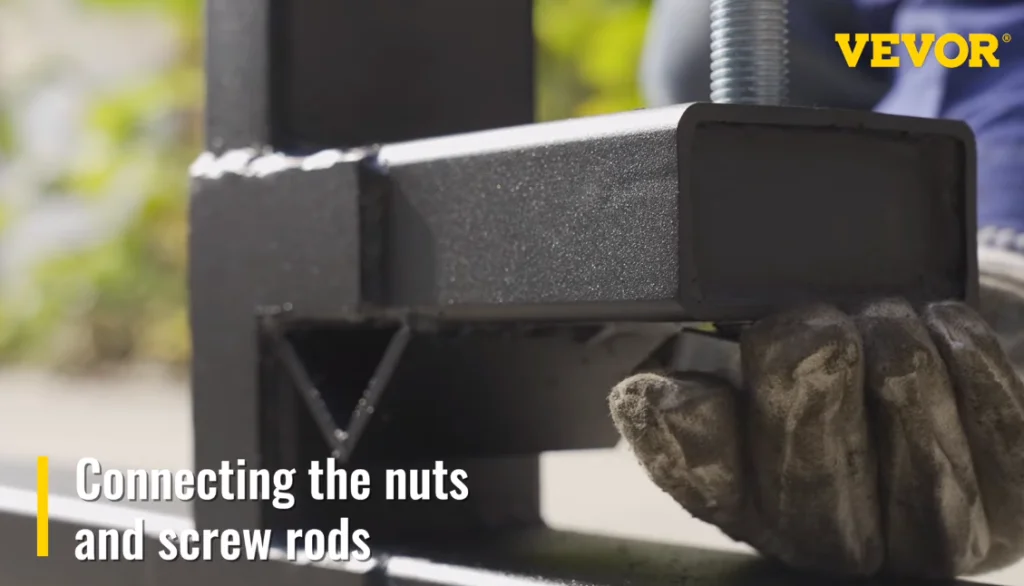

B. Pairing Nuts and Screw Rods

First, assemble the nuts and the screw rods. Place the forks holes with the screw rods holes so that they align. Put the screw rods through holes and finish tightening with the nuts. Make sure that the nuts are tightened tightly so they do not detach during use.

C. Attach the fork to the forklift

Then, fasten the forks to the forklift. Proceed by placing the forks below the carriage of the forklift, aligning them well. When the forks are in place, attach them to the carriage using the locking mechanism or bolts provided. This step is very critical in achieving stability and safety during operation.

D. Tighten the Screw Rod Clockwise

And now it’s going to adjust the position of the forks. With a wrench or another appropriate tool, turn the screw rods clockwise. This will either raise or lower the forks as required to the lifts the desired load. Adjust the two forks equally to keep the balance and stability.

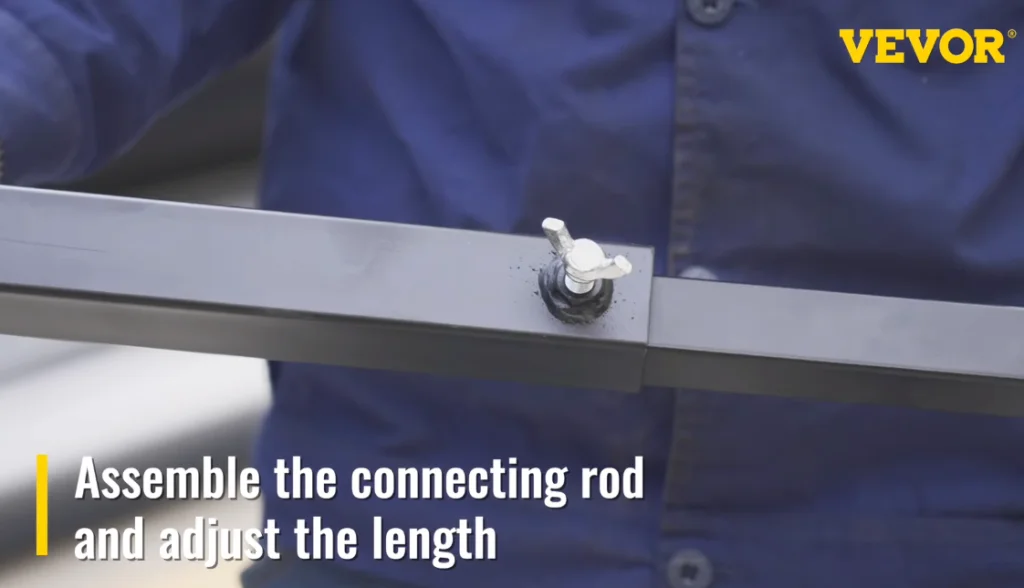

E. Assemble Connecting Rod and Check the Length.

Now bolt the connecting rod. Adjust the length of the connecting rod to match the width of the load that you will be lifting. Such things are usually achieved by loosening the adjustable sections of the connecting rod and then moving them to the desirable positions. After that, tighten the sections and fix them in a way to lock the connecting rod.

F. Add the connecting rod (Tighten the screws)

It’s now time to put the connecting rod whose length has been adjusted to the appropriate value on the forks. Place the connecting rod in between the two forks, checking the centrality and position of the rod. Fasten the connecting rod with the screws provided. Make sure that you have the screws tightly in place to prevent any movement or slippage during the use.

G. Installation Finished

Congrats, you have successfully installed the forks! Take a pause to check all the connections and that everything is securely tightened. This will minimize the chances of any misfortunes or faults during operation. Once the forks are installed correctly, you are now set to lift and shift loads using your forklift.

H. Put Big Stuff On Forktail

After the installation is done and you are ready to use the forklift, leave the heavy things on the forktail. Place the load evenly on the forks ensuring it is stable and secure. Make sure not to exceed the rated load for the forks to avoid damages or accidents. With appropriate load techniques, you will be able to safely lift heavy objects using your forklift.

Troubleshooting Common Issues

The following are some common issues that arise when installing forks on your tractor bucket and their solutions:

- Fork misalignment is a significant concern during installation. Misalignment of forks with the mounting bracket leads to uneven weight distribution. It might occur due to improper attachment or placing your tractor on uneven surfaces while attaching the forks. Ensure both forks are parallel to each other to align them accurately. Use alignment tools to get better results.

- Different loads require different adjustments to ensure stability during transportation. Ignoring the adjustment can lead to instability. Adjust the spacing between forks to achieve stability. You need to increase the spacing between the forks to lift heavier items. It will evenly distribute the weight and offer stability. In contrast, if you are dealing with small items, narrow the gap between the forks. It will provide better support.

- Wearing and loosening threaten the structural integrity of the machine and can lead to accidents while working. Regular maintenance can significantly lower these risks. Check for any signs of wear or loosening to eliminate damage risks. Tighten any loose bolts. Replace damaged or cracked components.

- Attaching and detaching forks with a tractor bucket is time-consuming. Difficulty in attachment and detachment can slow down operations. If you experience any issues while attaching or detaching your forks, inspect the attachment mechanism to determine the problem. Proper fork alignment and lubricant usage can facilitate smooth attachment and detachment. Moreover, following the manufacturer’s instructions can also streamline these procedures.

- Another common issue is unstable load handling. Lifting loads that are heavier than the forks’ maximum load capacity can damage the machine. It can also break your forks. You need to know the load capacity of your forks to smoothly carry the load.

Conclusion

Finally you acquired essential information on the fork installation on a farm tractor bucket. The right fork for your tractor bucket is crucial not only for efficiency but also for safety. Be aware that picking the right fork can help you to achieve maximum productivity and reduce the risk of an accident. Take action now by looking VEVOR line of Palette Forks products, which provide forks of different kinds for tractor buckets. Whether you’re dealing with farm work or industrial operations, picking the best fork is a necessity to get the best result. Don’t wait, take action and make your tractor bucket effective and useful for different purposes.