| Difficulty Level | Estimated Cost | Duration |

|---|---|---|

| 6 out of 10 | $100-$300 | 1-2 days |

Tired of space-consuming and propane set up and waiting for good weather to brew outside? Of course, homemade beer is the best, but we know it can be a hassle if you have tried making it at home. It may be time-consuming, or sometimes the product is not primitive and user-friendly.

With VEVOR, all in one brewing system makes your work as simple as you think. You can make grain beer at home without spending a fortune. To make a hard cider, add yeast to apple cider, sanitize the conditions, and allow the yeast to convert sugar into alcohol. But there’s more to understanding this. No need to worry; this guide will eliminate all your questions and confusion when choosing the best electric brewing system.

This article explores how the VEVOR electric brewing system can change your life with its extensive commercial brewing capacity. So let’s dive into reviewing VEVOR electric brewing system.

Items required for this project

Before start making a beer, you need a few essential items for this project:

● German Wheat

● German Pilsner

● Chocolate Malt

● Sparge

● Yeast

● Hers

● Bucker

● Spat

● Holler

● Tile Blunt

● Hops

● Bucket

● Gravity Reading

● Goldings

● Trash Barrel

Unboxing the All-In-One Beer-Making Machine

Now it’s time to unbox our VEVOR beer-making machine. Let’s check out what you’ll get in this package upon buying a VEVOR beer-making machine:

● Inner Pot

● Circulating Arm

● Condensing Coil

● Filter Screen

● User Manual

● Circulating Pump

● Brewing Pot

Features

● Brew Beer In Just 7 Steps

● Circulating Water Pump

● LCD Display

● Efficacious Cooling Coil

● Saccharification in full

● A large brewing capacity

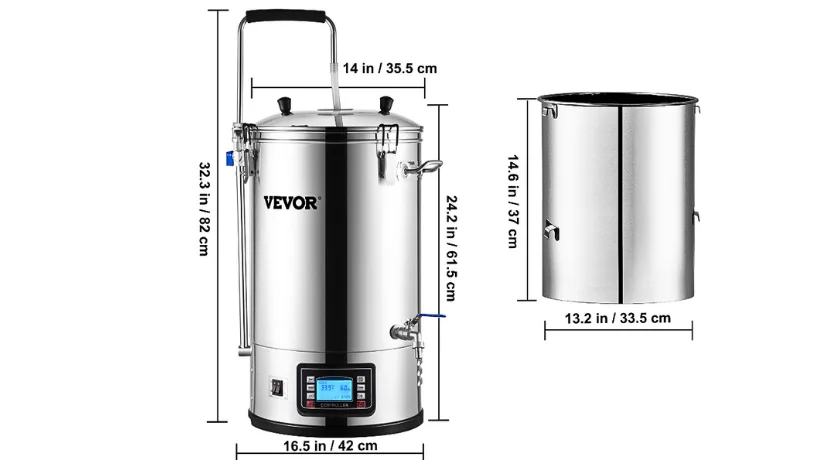

This VEVOR stainless steel is suitable for many purposes, like home and commercial usage. A condensing coil is 8.8 m in length and 48.5 cm in height. It’ll cool the wort upon boiling, so rapid cooling will be achieved this way. In addition to manual and automatic settings, this device is suitable for beginners and professionals.

With its lightweight design, it can easily be placed in your basement, kitchen, or patio. With this all-in-one brewing system, you can now enjoy your own homemade beer after a hard day’s work.

How to Make a Dunkel Wheat Beer With the Home Brewing Machine? Step-by-Step Guide

Let’s start making delicious beer as a perfectly happy man has beer in his mouth. Gather all the items in one place before starting the making process.

Step 1– Fill the brewing system with 6 and a half gallons of water, turn it on, start heating it, and get your grains ready.

Step 2– Add six pounds of German pilsner and wheat and 1/2 pound of chocolate malt and grind all of these things together after getting a 160-degree temperature.

Step 3– Add grains to the brewing system, cook it for an hour, and start stirring it well. After a few minutes, add a lid on the brewing system, turn on a circulating pump, and close it.

Step 4– When the water will circulate over the grain. You’ll notice circulating water over the grain after pulling from the bottom of the basket.

Step 5– Now, after an hour:

1. Take off the lid and sparge.

2. With the side hook, lift the whole thing up.

3. Start sparging to remove all the sugar, but it doesn’t rinse the grain off.

After this, pull this basket out and place it aside.

Step 6– The next step is to add ounces of bucker, hers, holler, spat, and tile blunt to the hot basket that is included with this electronic brewing machine. Add the hops packet to the mixture. For 90 minutes, boil it.

Step 7– After 90 minutes, remove the hot basket from the brewing system. Further, we will cool the grain mixture by placing the wart chiller in the brewing system and putting all its pipes in the trash barrel with some ice. Before doing this, ensure that all items are sanitized.

Step 8– You’ll need an adapter to run this little hose. To make your beer smell good, add some goldings and some hops and let it cool down.

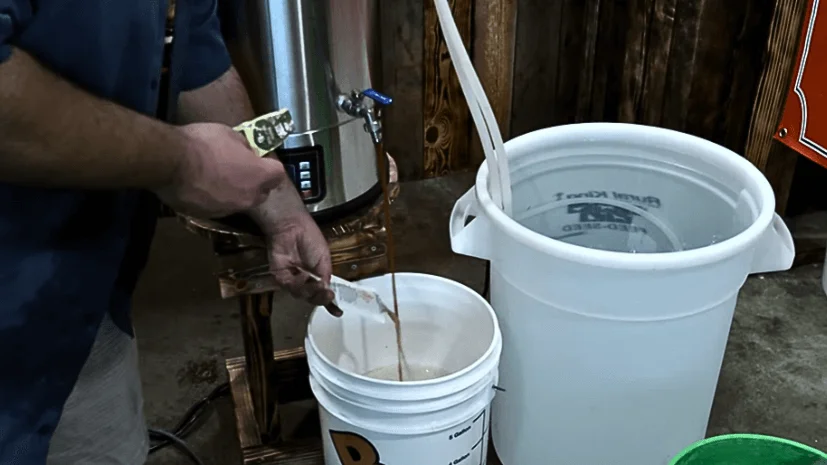

Step 9– Later on, when it gets cool down. Take a reading with a gravity reading tool; the measurement should be between 1.040 to 1.050 when you want a beer. Now let’s move your beer from the brewing machine to the bucket.

Step 10– While beer is getting transferred from the brewing system to the bucket, add German Ale Cole and white yeast into the bucket and start mixing up.

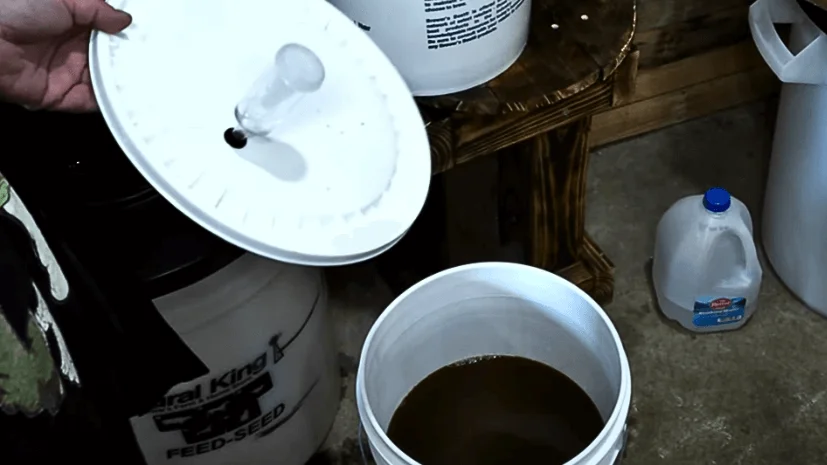

Step 11– When your beer’s gravity is over 1.050, add water to it so it goes down where you want it. Now put a lid and airlock on it and wait for a few weeks.

Step 12– Now, after waiting for a week, your beer is ready. Now transfer this mass of sludge and yeast into another bucket, but if you add both packs of yeast, as I showed you, it’ll get fermented in two days, as it moves from 1.050 to 1.0 per day.

Step 13- Now, put the lid on the bucket and let it sit for another week.

Step 14– Now it’s time to carbon your ready beer. You can do this in two ways; for a minute, add some dexto bottle or keg it. But kegging beer is clean. For this, you don’t need to yeast sediment in the bottom of the bottle-also you don’t have to wait for a couple of weeks. A VEVOR Keg is the best because it can be refrigerated to keep the beer cold. The carbon in the keg takes a day or two to carbonate the beer. But still, two days are better than a couple of weeks.

Step 15– So transfer some beer from the bucket and add it into a keg through the pipe.

Step 16– After transferring the beer into a keg, add some gas. Start rolling it and put it in the fridge as it’ll get aside and put beer in it for a day.

Brewing with this system is very simple. On the jet control, a button can be pressed to adjust the power. To determine when the beer is ready, use the timer, and you will hear a beep when the temperature reaches boiling.

FAQs About Making Dunkel With Brewing Machine

1- What is the process of making Dunkel?

The process of making Dunkel involves a series of steps, including mashing, boiling, fermenting, and bottling. Malted grains are mashed to extract sugars, then boiled with hops to add bitterness and aroma. After cooling, yeast is added for fermentation, and the beer is aged before bottling. For Dunkel, darker malts are used, resulting in its characteristic rich and malty flavor.

2- Is CO2 used in the production of beer?

Yes, CO2 is commonly used in the production of beer. During fermentation, yeast consumes sugars and produces alcohol and CO2. In closed systems, CO2 is trapped and naturally carbonates the beer. Additionally, CO2 is often used to carbonate and package beer, giving it the desired fizziness.

3- How does a brewing machine make Dunkel beer?

A brewing machine automates the process of making Dunkel beer. It starts with mashing, where grains are mixed with water at precise temperatures. After mashing, the machine automatically transfers the wort to the boiling phase, where hops are added for flavor. Following boiling, the wort is cooled, yeast is introduced, and fermentation begins. The brewing machine ensures temperature control and monitors fermentation. Once complete, the machine aids in bottling or kegging the finished Dunkel beer.

Conclusion

You will no longer have to worry about fermentation space being limited in carboys because the VEVOR electronic brewing system has an airlock with a blow of tube. It is too small to be placed anywhere; besides this, you can purchase this product for just a few dollars. Take advantage of VEVOR’s discount program and buy Brewing Machine without delay.