You use engraving machines to carve intricate patterns and shapes on different surfaces. So, with these machines, you can add information to a product, such as serial numbers or measurements, and you can also add personalized texts to surfaces that are sentimental or special to you. These machines are unique, and there are many types of engraving machines with differences in quality, strength, flexibility, and precision.

One of the best engraving machines you can find anywhere on the market is the VEVOR CNC 3018 engraving machine. This machine is not only precise, but it is one of the strongest you will come across. Therefore, this article goes into detail about every information you will need on how to use a VEVOR Engraving Machine. However, before we do that, let’s explore what you can do with a CNC Engraving Machine.

Table of contents

What Can You Do With a 3018 CNC Engraving Machine?

With a CNC engraving machine, you can create exquisite and intricate texts and patterns on different surfaces, ranging from wood to plastic. Therefore, with the machine, you can make personal engravings on furniture or even cutlery that means something to you. Besides, if you are a woodworker, CNC engraving machines help you create designs that customers may love or even specifically request. Apart from making designs and patterns, you should also note that you can use a VEVOR engraving machine to cut or engrave on different materials such as wood, plastic, and wax.

How Does the CNC Engraving Machine Work?

The CNC engraving machine uses computer-aided design (CAD) and computer-aided manufacturing (CAM) software to create intricate patterns on a workpiece. The entire process starts with the designer creating a visualization of the pattern in the CAD software. After the designer has done this, he uses CAM software to generate a process for the CNC engraving machine. With the CAM, he selects the necessary tools, tool path, and process pattern that the CNC engraving machine will follow. Finally, the CAM software will generate a G-code file written in syntax, which the CNC engraving machine can decode.

Next, the CNC engraving machine operator will set the workpiece, that is, the surface where the pattern is to be engraved, into the machine. Here, it is crucial that the workpiece is well-placed and leveled to avoid any errors. Lastly, the engraving process starts, and the machine automatically creates the pattern without interference.

Now that you know how the CNC engraving machine works, the following section helps you understand how much it will cost to get it.

How Much Is the VEVOR Engraving Machine?

The VEVOR CNC 3018 Engraving Machine costs $145 and specific additional shipping costs for locations outside the United States. Note, however, that you can get it at a cheaper price by becoming a VEVOR member. As a VEVOR member, you typically get the lowest prices on about 50% of VEVOR products, plus reward points for purchases from VEVOR. These reward points can be used on future purchases, and the higher your level as a member, the more points you earn.

Product Review: VEVOR CNC 3018 Engraving Machine

The VEVOR CNC 3018 engraving machine is one of the best engraving machines you can find. It has a range of amazing features that should make it your go to device. Some of these features are:

- It can be used to engrave a wide range of materials, including plastics, soft aluminum, PVC, PCB, acrylics, and many more

- The VEVOR engraving machine is equipped with three stepper motors that guarantee precision, and it supports almost every software you may use to import files in G-code format for engraving. Examples? Windows 7, Windows 8, Linux, and MacOS, amongst others.

- The VEVOR engraving machine has a frame that js largely made from bakelite materials and aluminum alloy, which makes it strong and durable.

- It has an upgraded control board that allows offline access. In case you are wondering, some of the effects of offline access are that you can use the VEVOR engraving machine without a computer and can randomly select offline files for engraving. You don’t have to wait to be online to use the machine.

- Last but definitely not least, the rating for the VEVOR engaging machine is between 4.7 and 4.8, ranging across price, quality, and features. This means that users consider the VEVOR CNC 3018 engraving machine worth the cost.

The implication of all these is that with this machine you don’t need to worry about precision, durability or limited accessibility. Its excellent motors, aluminum frame and upgraded control board make it dependable for all your engraving.

Now that we have discussed everything else, it is time to go through the step-by-step process of using the VEVOR engraving machine.

Steps On How To Use VEVOR CNC 3018 Engraving Machine

To use the VEVOR engraving machine, there are five simple steps to follow, and we highlight each of them below:

Step 1: Assembly

After purchasing your VEVOR CNC 3018 engraving machine, the first thing to do is assemble it according to the instructions. You will find these instructions in the user manual and installation video that accompany your VEVOR engraving machine. Do not worry; the instructions are simple and easy to follow.

Step 2: Software Installation

When you finish assembling your device, the next thing is to install your preferred CAD and CAM software. To do this, get your software and follow the instructions that come along with installing it. Also, note that there is one general principle for installation – after getting the software on your CNC router, just keep clicking“next” until you get the notification that says your installation was successful.

Step 3: Materials to work with (plastic, wood, soft aluminum, etc)

Here, what you do is place your workpiece into the CNC engraving machine. At this point, it is important to note what material the VEVOR engraving machine can work on. These materials include soft aluminum, plastic, wood, and PVC.

Check the user manual accompanying your VEVOR engraving machine for a complete list of materials.

Step 4: Test Run

As soon as you place your workpiece correctly into the engraving machine, your next point of duty is to test-run your VEVOR CNC 3018 engraving machine to see if it works well. At this point, take note of the pattern you expected and your final result. Also, be sure to check that you placed your workpiece correctly if you notice any errors.

Step 5: Working Offline

Last but not least, note that you can work offline with the VEVOR engraving machine. This is made possible by the upgraded control board, which allows offline control and access. Some of the benefits of this offline controller include the fact that you will not need to connect to a computer everytime you want to work and that you can manually adjust the X, Y, and Z axes’ position as starting points for engraving. Furthermore, offline control ensures you can randomly select any offline file for engraving.

Key Takeaways

- The VEVOR CNC 318 engraving machine gives you the best any CNC engraving machine offers. You can expect precision and strength when engraving, and you can engrave patterns and unique texts on various surfaces, ranging from plastic and wood to soft aluminum and PVC.

- To use the machine, you first assemble it according to the instructions in the manual. After this, you will install the software and visualize your pattern. Then, the next thing is to load your workpiece into your engraving machine before finally test-running it. Note also that you can use your VEVOR engraving machine offline.

The VEVOR CNC 3018 engraving machine is an effective tool you can quickly learn to use. You should purchase it for all your engraving needs today. What’s more about this tool? Check some of our frequently asked questions below.

FAQS About VEVOR Engraving Machine

1. What is the difference between a CNC machine and an engraver?

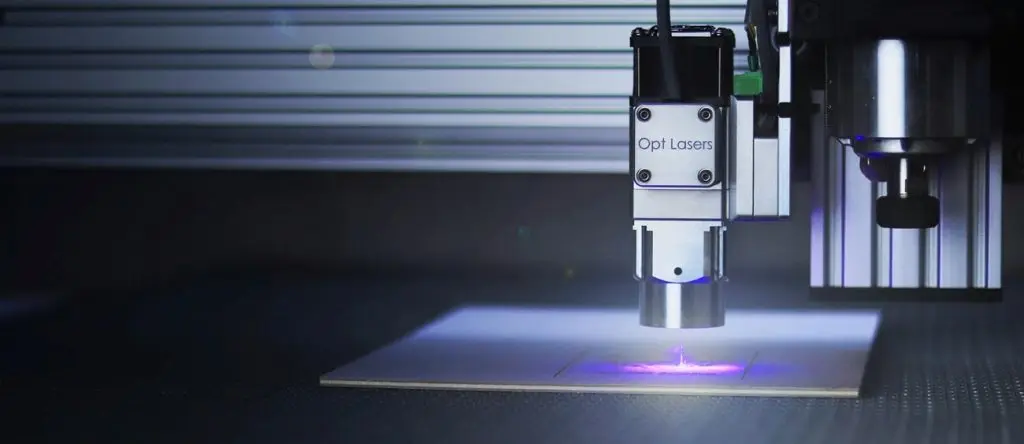

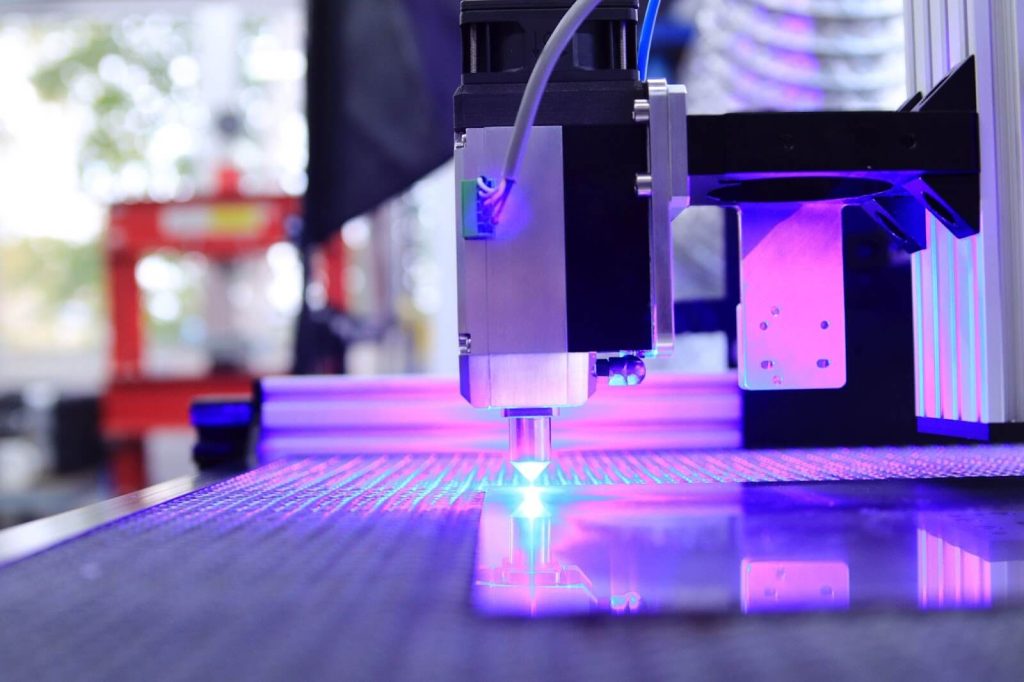

Two significant differences exist between a CNC engraving machine and a laser engraver. The first is that a CNC tool makes use of a cutter head to engrave and make patterns in materials. On the other hand, the laser engraver uses the high energy of a laser to engrave and cut a material. The second difference is that you typically use the CNC engraving machine for thicker materials than the laser engraver.

2. Can you engrave with a CNC machine?

Yes, you can engrave with a CNC tool. In fact, it is one of the most precise ways to etch a pattern or text on surfaces.