The invention of hydraulic floor jacks has played a key role in various industries as an efficient and safe way to lift heavy loads. However, over time these tools may begin to lose steam due to wear and tear. This is why regular maintenance is required to ensure they continue to provide optimal performance.

In cases where maintenance is neglected, minor to major issues such as corrosion, leaks, and failure to lift might happen. These scenarios can be costlier than adhering to actual maintenance routines, and in some cases, they might even lead to injury and accidents. So, it’s best to nip the issues in the bud before they become serious.

It is also important to mention that the choice of jack you buy will determine lifting efficiency, durability, and optimal performance. For the best outcome, we recommend the VEVOR hydraulic floor jack. This jack is designed to be sturdy and long-lasting. Also, VEVOR ensures that customer support is readily available to users of their products, so customers can get quick tips and support for maintaining their jack.

In this guide, we provide tips on hydraulic floor jack repair and how to maintain the tool properly. We also provide a step-by-step guide on how to troubleshoot common issues with your hydraulic floor jack.

Table of contents

- Understanding Your Hydraulic Floor Jack

- Tools and Materials Needed for Hydraulic Floor Jack Repair

- Step-by-Step Guide to Fixing Common Hydraulic Jack Issues

- Repairing a Leaking Hydraulic Floor Jack

- Solving Incomplete Lifts

- Preventive Maintenance Tips for Hydraulic Floor Jacks

- When to Seek Professional Help

- Why Choose VEVOR for Your Hydraulic Floor Jack Needs

- Frequently Asked Questions About Hydraulic Jack Repair

- Conclusion

Understanding Your Hydraulic Floor Jack

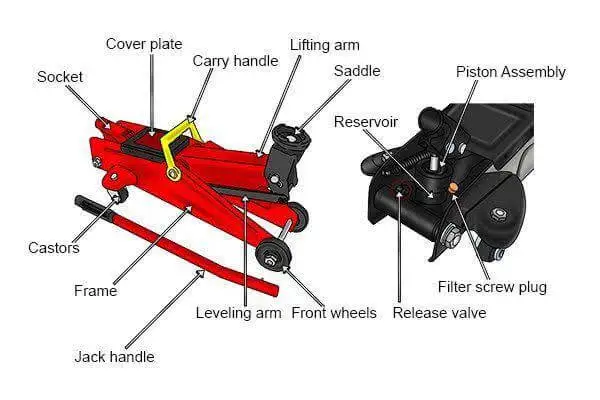

To better understand your hydraulic floor jack, it is essential you understand how it works and the common issues that may affect it. This can help with enhancing your maintenance culture and fixing minor issues that might arise.

How Does a Hydraulic Floor Jack Work?

The working of the hydraulic floor jack is quite simple, as the whole process is undertaken when hydraulic fluid is pumped into the cylinder. The fluids which are transmitted by a system of valves and hoses control the hydraulic fluid’s flow.

Once this happens, the piston is forced to move upward thereby causing the lift arm or pad to respond to the upward pull. Since most hydraulic floor jacks use a pressurized pump, which can be electrical or manual, lifting the load becomes easier. For jacks like the VEVOR hydraulic floor jack, the process is even easier and more efficient, as very little human effort is required.

Once the load has been lifted to the desired level, the valves would close up and prompt the piston to be locked in place. To lower the lifted load, the same process ensues, as the valves open up and the hydraulic fluid flows back into the reservoir to cause a downward movement for the piston.

Common Issues with Hydraulic Floor Jacks

Common issues that you might encounter with a faulty hydraulic floor jack include:

- Incomplete lift

- Leaking floor jack

- Piston damage

- Overheating

- Corrosion

Tools and Materials Needed for Hydraulic Floor Jack Repair

If you are confused about how to repair a hydraulic jack, then you should know that the process is not much of a hassle as long as it’s a minor issue. However, it is essential to mention that there are some necessary tools that would be required to repair a hydraulic floor jack. So, having them beforehand can make the process much more seamless and efficient.

Essential Tools for Repairing a Hydraulic Jack

Here are some of the essential tools needed when fixing a hydraulic floor jack:

- Adjustable and fixed wrenches

- Pliers

- Socket sets

- Flatheads and Philips Screwdrivers

- Flashlight

- Replacement parts such as seals, pistons, O-rings.

Safety Gear and Precautions

Before you start working on hydraulic car jack repairs, it is best to know the necessary precautions to take and make safety a priority. This is because hydraulic fluids can be hazardous if not handled properly. Also, the parts of the jack might be heavy and difficult to handle. So always make sure you follow these safety precautions on how to repair a hydraulic floor jack:

- Wear safety goggles

- Ensure your workspace is adequately ventilated

- Wear protective gloves

- Avoid getting close to open flames or sparks

Step-by-Step Guide to Fixing Common Hydraulic Jack Issues

Most hydraulic floor jacks are designed to be sturdy and reliable, however as stated earlier, they might encounter some issues along the line due to several factors. It should be noted that most floor jack repairs are doable with the right knowledge. In this section, we will walk you through a step-by-step guide and common DIY tips on how to fix hydraulic jack issues.

How to Fix a Hydraulic Jack Not Working

Here are practical DIY steps on how to fix hydraulic jack not working, or those that wouldn’t lift or lower.

Inspecting for Air Bubbles

The first thing to do when you notice a failure to lift or lower is to inspect the hydraulic system for possible cases of air bubbles. Yes, this happens and can disrupt the proper function of your floor jack. So, what you want to do is check the pump, valve, and hose connections for any signs of fluid droplets or barely discernible hissing sounds.

Bleeding the Hydraulic System

The next thing to do is bleed the hydraulic system by loosening the bleed screw, so the air in there can escape. Once you notice that the hydraulic fluid is flowing out, then tighten the bleed screw. You also want to collect the fluid and check for possible signs of contamination.

Refilling Hydraulic Fluid

If there is any sign of contamination in the fluid then it’s best to replace the fluid with one that is compatible with the jack. Do that and ensure it is filled to the recommended level.

Repairing a Leaking Hydraulic Floor Jack

For cases where the jack is leaking fluids, here are actionable tips to take in fixing it:

Identifying the Leak Source

The first step to take is to inspect the jack’s component and look out for any suspicious leak spots. The culprits are usually the hose connections, valve stems, O-rings, or seals.

Replacing O-Rings and Seals

If you find out that the O-rings and seals are damaged, then it’s best you replace them. Try to ensure that you properly install and tighten them, but also you need to avoid over-tightening. You should also apply a bit of hydraulic fluid to the new seals and O-rings, as this helps with easy installation and improved sealability.

Solving Incomplete Lifts

If your hydraulic jack won’t lift to the maximum height, then you can try out these tips to fix it:

Checking the Release Valve

Most times, the issue is with the release valve, as it might not be fully closed. So check if it’s stuck and if there’s an issue, you can either clean or replace it. You should also check the valve stem for possible corrosion and lubricate it if there is any need for it.

Inspecting the Pump Piston

You should also check the pump piston and cylinder for possible corrosion. If necessary, they should be replaced, as neglect could further damage the jack.

Preventive Maintenance Tips for Hydraulic Floor Jacks

Preventive measures are an excellent way to ensure your floor jack is durable and safe to use. With these tips, you would be able to ensure that your priced floor jack lasts long, and cuts out the possibility of your floor jack not working abruptly.

Regular Inspection and Lubrication

Whether you use your hydraulic floor jack regularly or periodically, there are two things you need to take into consideration – regular inspections and lubrication. These are the backbone of achieving longevity for this tool, and these routines need to be done judiciously. When doing these checks, these are a few things to do:

- Checking for signs of damage or leakage.

- Checking the hydraulic hose for damages.

- Lubricating the moving parts.

- Inspecting the fluid levels and conditions.

- Topping up the thin layer of fluid on the seals and O-rings.

Also, essential places to lubricate include:

- Moving parts

- Release valves

- Valve stems

- Ram and gland nut

- Pump cylinder

- O-rings and seals

Proper Storage and Handling

You should also ensure that your jack is stored and handled properly, as this can prevent accidental damage and prevent common issues. When storing your jack, here are a few things to consider:

- Always keep the jack in a standing position

- Avoid extreme temperatures

- Use a jack stand whenever necessary

Notable tips for handling the jack include:

- Using the right lifting techniques

- Avoiding sudden drops or impacts

- Avoiding the application of chemicals or corrosives to the jack

When to Seek Professional Help

With the tips we have provided in this content, you might feel that you have gained enough DIY skills to fix your floor jack issues. Well, you are right. However, there are some floor jack-related issues that might require a professional touch to help mitigate further damage. This section discusses the signs that will indicate you need professional help.

Identifying Complex Issues

If you are confused about when to get help, here are some pointers that should help. Seek help when you notice:

- Extensive damage or corrosion

- Complex hydraulics or electrical damage

- Loosening specialized screws

- Complicated repair process

Choosing a Professional Repair Service

Now that you are sure you require professional help in fixing your hydraulic floor jack, then it’s essential you look out for reputable repair businesses. Ensure that they have experience in hydraulic floor jack repairs and have a team of qualified technicians. Customer reviews can also be essential in making your choice, as most users would leave feedback based on their experience with such businesses.

Recommended For Your Project

Why Choose VEVOR for Your Hydraulic Floor Jack Needs

The power tool market is rife with various brands putting out products to rival each other on the basis of price point and quality. However, we are of the opinion that VEVOR has earned a reputation for high-quality hydraulic floor jacks which are designed for professionals and DIYers alike. The brand has a track record of reliability and quality performance when it comes to its tools. We further discuss why you should choose the VEVOR hydraulic floor jack below.

Quality and Reliability

With a commitment to ensuring their customers get quality products, we can say that VEVOR is quite reliable. Their hydraulic floor jack has undergone a series of tests for longevity and reliability under heavy loads. This is actually impressive, as we can count on them to provide us with these types of solid tools.

Customer Support and Warranty

For most customers on the lookout for a quality hydraulic floor jack, making the right choice is one of their biggest worries. This is one thing we know that VEVOR considers, as they have prioritized putting the customers first by providing them with a dedicated after-sales service.

The brand also provides customers with a warranty program that ensures some confidence in their product. Customers who purchase a VEVOR hydraulic floor jack, get a 12-month warranty that covers manufacturing defects and any other issues. There is also a team of customer support representatives who are readily available to provide prompt and insightful responses.

Frequently Asked Questions About Hydraulic Jack Repair

This section covers some of the frequently asked questions we get concerning hydraulic floor jack repairs and the answers from our top technicians.

How Often Should I Service My Hydraulic Floor Jack?

The choice of how often you should service your hydraulic floor jack is dependent on usage. It is advisable that you service your jack every 6–12 months. However, this is dependent on the product or manufacturer.

What Type of Hydraulic Fluid Should I Use?

The choice of hydraulic fluid to use is vital to the longevity of your tool. However, it is best that you consult the owner’s manual to find the recommended fluid type or viscosity. You can also reach out to a professional who would help with making a decision.

Can I Repair a Hydraulic Jack Myself?

The straightforward answer to that is YES. You can undertake your hydraulic floor jack repairs yourself. But there are cases where you might require more than DIY tips to fix your floor jack issues. This is when you would need to consult with a professional to help mitigate more damage. However, when it comes to minor issues, you can give it a try using the tips above.

Conclusion

Hydraulic floor jacks are valuable tools that require adequate maintenance and occasional repair so that they don’t get damaged. Once you understand these tenets, you can ultimately extend the longevity of the tools and enhance the value for your money. It’s also essential that disregard or utter neglect of your hydraulic floor jack can cost you a lot in repairs, accidents, damage, and downtime. So ensure you care for and maintain them appropriately.

If you are still on the fence concerning the best hydraulic floor jack to get, then we recommend that you go for the VEVOR models. Our brand has an assorted range of hydraulic jacks and accessories that would fit perfectly into your workshop or garage. Visit our website today to make a purchase!

Arabic

Arabic Danish

Danish Dutch

Dutch English

English Finnish

Finnish French

French German

German Hungarian

Hungarian Italian

Italian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Spanish

Spanish Swedish

Swedish