Maintaining your ice machine isn’t just about keeping it running; there is more to it. Ensuring your ice machine not only operates smoothly but also produces pristine ice and has a prolonged service life can significantly cut down on repair costs. For this purpose, we have written down a detailed guide about the ice machine cleaning schedule.

In this article, we’ll dive into a maintenance checklist that covers everything from water systems to key components like the condenser coil.

Plus, we’ll talk about schedules. Mastering the timing of cleanliness is just as vital as grasping the methods.

Last up, we answer common questions head-on. Slow ice production? Mold issues? Get ready; answers are coming your way.

Table of contents

Importance of Ice Maker Maintenance

Let’s break down why your ice maker needs regular cleaning and maintenance. In this section, we will take a look at how keeping up with maintenance can bring about a huge difference to your machine’s service life.

Optimizing Performance and Efficiency

A well-maintained ice machine works smoothly, churning out ice very fast. Regular cleaning prevents mineral build-up, which can slow down production and lead to higher energy bills. Keeping components in tip-top shape means your machine doesn’t have to work as hard, saving you money on utilities over time.

Crystal Clear Ice

No one likes their lemonade or morning coffee served with cloudy ice. Proper maintenance ensures each cube is clear and pure, thanks to regular filter changes and sanitization processes that remove impurities from the water before it freezes. This attention to detail makes every drink look and taste better. Thus, if you want fresh ice each time, ensure you change the ice filter regularly.

Extending Lifespan

Treating your ice machine right can mean fewer breakdowns and a longer life expectancy. Keeping your ice maker clean and well-maintained can make a huge difference in extending its life span. All the regular checking, cleaning, and timely repairs can extend its service life.

Minimizing Downtime

A scheduled cleaning might take an hour, but finding parts for repair could disrupt the functioning of your ice maker for days or even weeks during peak season. Regular maintenance is a small price to pay for keeping operations uninterrupted and avoiding the hassle of sudden breakdowns.

Minimal Repair Costs

Lastly, reducing wear and tear through consistent upkeep helps avoid costly repair emergencies down the line. Because, let’s face it, no one wants to drop big bucks fixing something that could’ve been prevented in the first place.

Ice Maker Maintenance Checklist

Caring for your ice machine goes beyond mere operation; it’s about guaranteeing the ice produced is clean, free of contaminants, and wholesome for drinking. Diving into this guide will ensure your ice maker remains pristine and operational. Below, we have listed down a checklist that can help you keep ahead of your maintenance schedule.

Water System/Supply Line/Inlet Valve

The heart of any ice machine is its water system. Start by checking the supply line and inlet valve for any signs of leak or damage. A compromised supply line can introduce contaminants into your ice, so replacing any faulty parts promptly is crucial.

A clean water filter not only ensures tasty, odor-free ice but also protects the internal components from scaling and clogging.

Key Components: Condenser Coil, Thermostat, Evaporator Plate

Your condenser coil works hard to dissipate heat. Keeping it dust-free boosts efficiency and prolongs lifespan. The thermostat controls temperature, which is vital for perfect cube formation, while the evaporator plate directly impacts ice quality. All these components should be checked regularly so there are no sudden breakdowns of the machine.

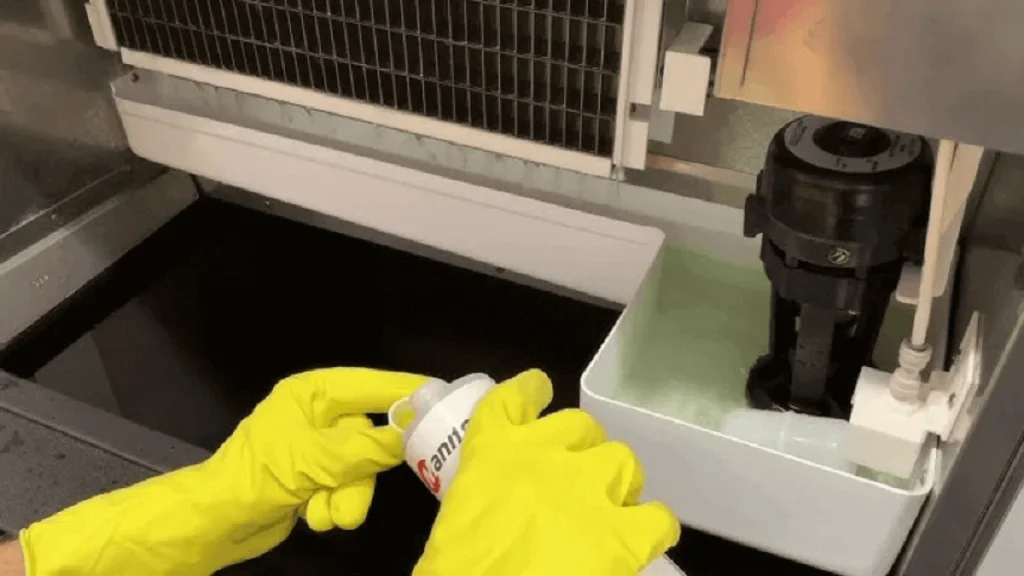

Cleaning & Sanitizing

Icy build-up inside? That’s a no-go. Regular cleaning prevents mold growth, which could leave a bad impression on your customers. Also, don’t forget sanitization because it’s like giving your machine an immunity boost against germs.

Ventilation & Drainage

Adequate ventilation keeps things cool under pressure, while proper drainage ensures there are no standing pools of water where bacteria could accumulate. Thus, to keep your ice maker running smoothly, you need to check it has proper ventilation as well as a drainage system.

Ice Machine Cleaning Schedule

As discussed above, looking after your ice machine goes beyond functionality and appearance; it’s fundamentally about preventing your ice from mold build-up, bacterial accumulation, and contamination. So, let’s break down the cleaning schedule to keep your ice maker machine clean and clear.

Daily/Weekly/Monthly/Quarterly/Annually Schedules:

Daily tasks might sound overkill, but they are very important to keep your ice maker running. Every day, wipe down the exterior surfaces and check for any signs of scale build-up or unusual frost patterns. This quick once-over can prevent bigger issues down the line.

On a weekly basis, dive deeper by inspecting the storage bin and scoops for cleanliness because these areas are hotspots for germs if neglected. Monthly chores include descaling and sanitizing water system components, which is crucial in hard water areas to avoid mineral deposits clogging up your system.

When we talk about quarterly maintenance, think big picture: It’s time to check on air filters (if applicable), clean them out, or replace them to ensure proper airflow through the unit. Last up, annually – yes, only once a year – schedule professional servicing that includes checking refrigerant levels and deep-cleaning coils and other key parts.

This routine may seem daunting at first glance, but integrating these steps into regular maintenance will prolong your ice machine’s life span significantly while making sure every cube that pops out is safe to use for chilling your drinks.

VEVOR Ice Machine for Crystal Clear Ice and Easy Maintenance

When it comes to ease of cleaning an ice maker machine, nothing can beat VEVOR’s ice machines. As you already know, keeping your ice machine in prime condition isn’t merely for aesthetics; it’s crucial for its performance, effectiveness, and durability. A well-maintained ice machine ensures you get crystal-clear ice every time without fail.

A VEVOR’s ice machine comes with a premium water filter, which gives clean and clear ice each time. It also has a professional electric drainage pump, which helps to discharge the water of melted ice effectively. Thus, you don’t have to worry about cleaning the ice maker all the time.

Features like a powerful pump, six-sided cyclopentane foam layer, and stainless-steel exterior can significantly reduce energy consumption while boosting output, a win-win situation for any business or home user.

A routine check-up prevents mineral build-ups that often lead to cloudy or off-tasting ice. By following simple yet effective steps towards maintaining your unit regularly, expect nothing less than perfection with each use.

FAQs about Ice Machine Maintenance

Although by this point, you have learned everything about ice machine maintenance, there are still some pressing questions that you may want to know the answers to. So, let’s find out.

How Often Should I Clean My Commercial Ice Machine?

Cleaning your commercial ice machine isn’t just good practice; it’s essential for crystal clear, taste-free ice. Aim to deep clean it every six months. But high-usage machines in areas with hard water might need more frequent attention, say quarterly. Remember, you don’t have to wait to see the signs of mold or mineral build-up to clean your ice maker. Regular cleaning keeps efficiency up and energy costs down.

Why Is My Ice Machine Making Ice Slow?

A slow ice machine could be signaling anything from dirty filters to low water flow or even temperature issues. First things first: check if it’s gasping through clogged air filters or battling grimy water lines—both are common culprits that throttle production speed.

If those look good, check if it is heating up due to poor ventilation. Machines in hot spots work overtime, cooling down before they can even start making ice. Sometimes, moving your unit just a few feet can make all the difference.

Why Is There Mold in My Ice Maker?

Mold loves moisture and darkness, two things an under-maintained ice machine offers. If mold has started showing up in your ice maker, it means cleaning has been put off for longer than needed.

To get rid of these unwelcome guests for good, incorporate thorough sanitization into your maintenance schedule alongside regular cleanings.

Conclusion

Regular ice machine maintenance means more than just a quick clean. Ensuring your ice machine operates at peak performance involves not only regular maintenance but also optimizing its output for quality ice and extending its lifespan to avoid expensive repairs.

From checking water systems to scrutinizing key components like the condenser coil, you need to keep an eye on everything. And let’s not forget about setting up a cleaning schedule – timing is everything.

If you are facing slow production or mold, it means your machine needs more regular cleaning. Ice machine maintenance isn’t just necessary; it’s crucial for quality and reliability. Begin to put into practice the knowledge you’ve gained, starting now. Your ice machine will thank you tomorrow.