What is A Meat Band Saw Blade?

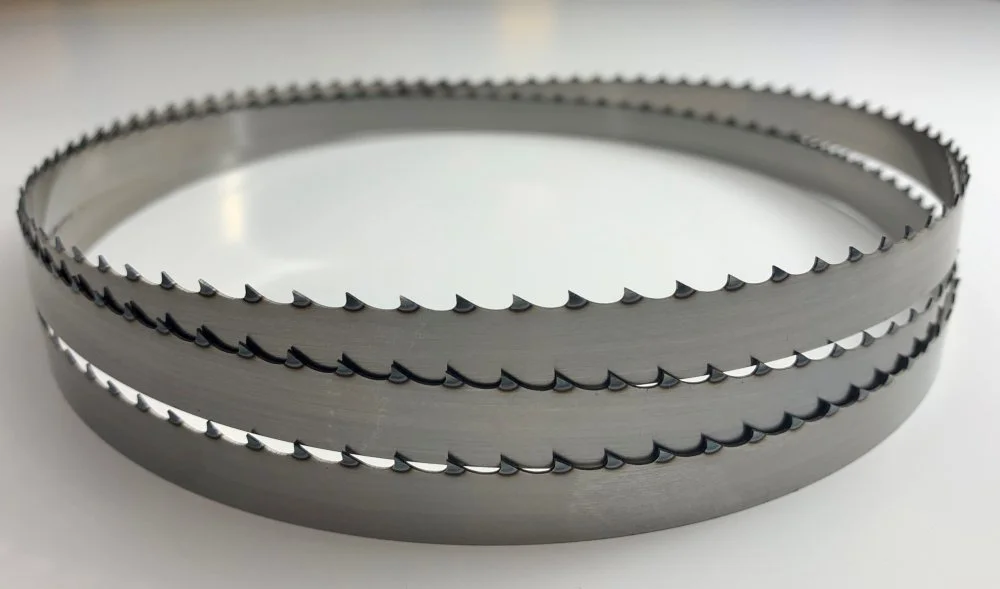

A meat band saw blade is a type of blade that is used in commercial or industrial meat processing equipment to cut through various types of meat. The blade is a long, narrow band of steel with teeth on one edge, and it is typically made from high-carbon steel, which is durable and resistant to wear and tear.

The blade is mounted onto a motorized saw and can be adjusted to different angles and heights to make different types of cuts, such as crosscuts, rip cuts, and thin slices. Meat band saw blades are available in a range of sizes and tooth configurations, depending on the type of meat being cut and the desired cut quality.

It’s important to note that meat band saw blades must be properly cleaned and sanitized after each use to prevent contamination and ensure food safety. They should also be regularly inspected for damage and replaced as needed to maintain their effectiveness and prevent injury to workers.

What Are the Benefits of the Meat Band Saw Blade?

A meat band saw blade is a specialized tool used in the meat processing industry to cut large cuts of meat into smaller, more manageable portions. Here are some of the benefits of using a meat band saw blade:

1. Improved cutting accuracy: A meat band saw blade is designed to make clean, precise cuts through meat, which improves cutting accuracy and consistency.

2. Increased productivity: Meat band saw blades can cut through large quantities of meat quickly, increasing productivity in the meat processing industry.

3. Reduced waste: The precise cutting ability of a meat band saw blade means less waste from uneven cuts or damaged meat, which can help save money for meat processing companies.

4. Improved safety: Meat band saw blades are designed with safety features to protect workers from injuries, such as blade guards and automatic shut-off mechanisms.

5. Versatility: Meat band saw blades can be used to cut a wide range of meat types, including beef, pork, poultry, and fish, making them versatile tools in the meat processing industry.

Factors To Consider When Choosing A Meat Band Saw Blade

When choosing a meat band saw blade, there are several important factors to consider:

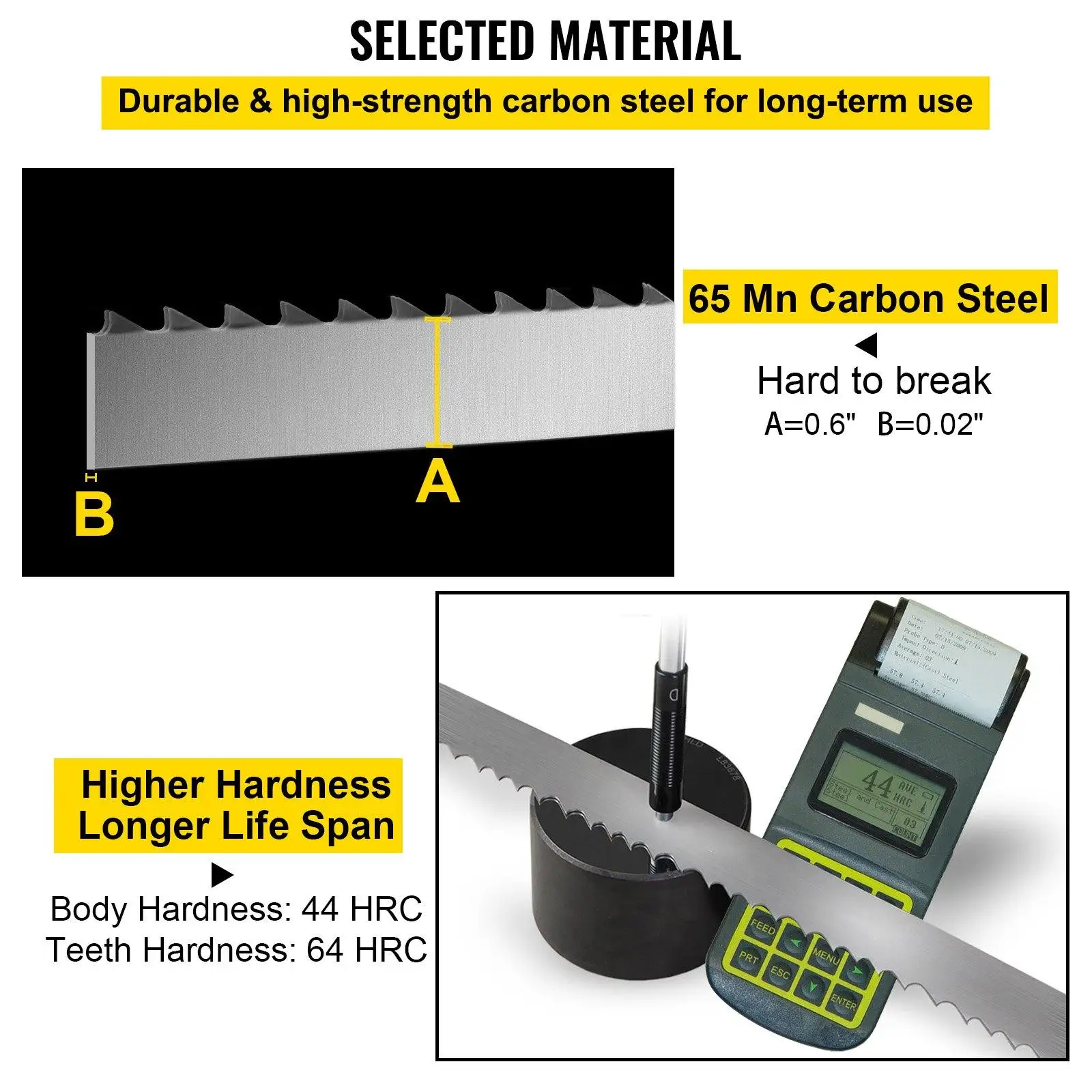

1. Blade Material: The material used to make the blade is an important consideration. Blades made of high-carbon steel, stainless steel, or bimetal are commonly used for meat cutting. High-carbon steel blades are ideal for cutting through bone, while stainless steel blades are rust-resistant and easier to clean. Bimetal blades are a combination of high-carbon steel and stainless steel, providing both durability and resistance to rust.

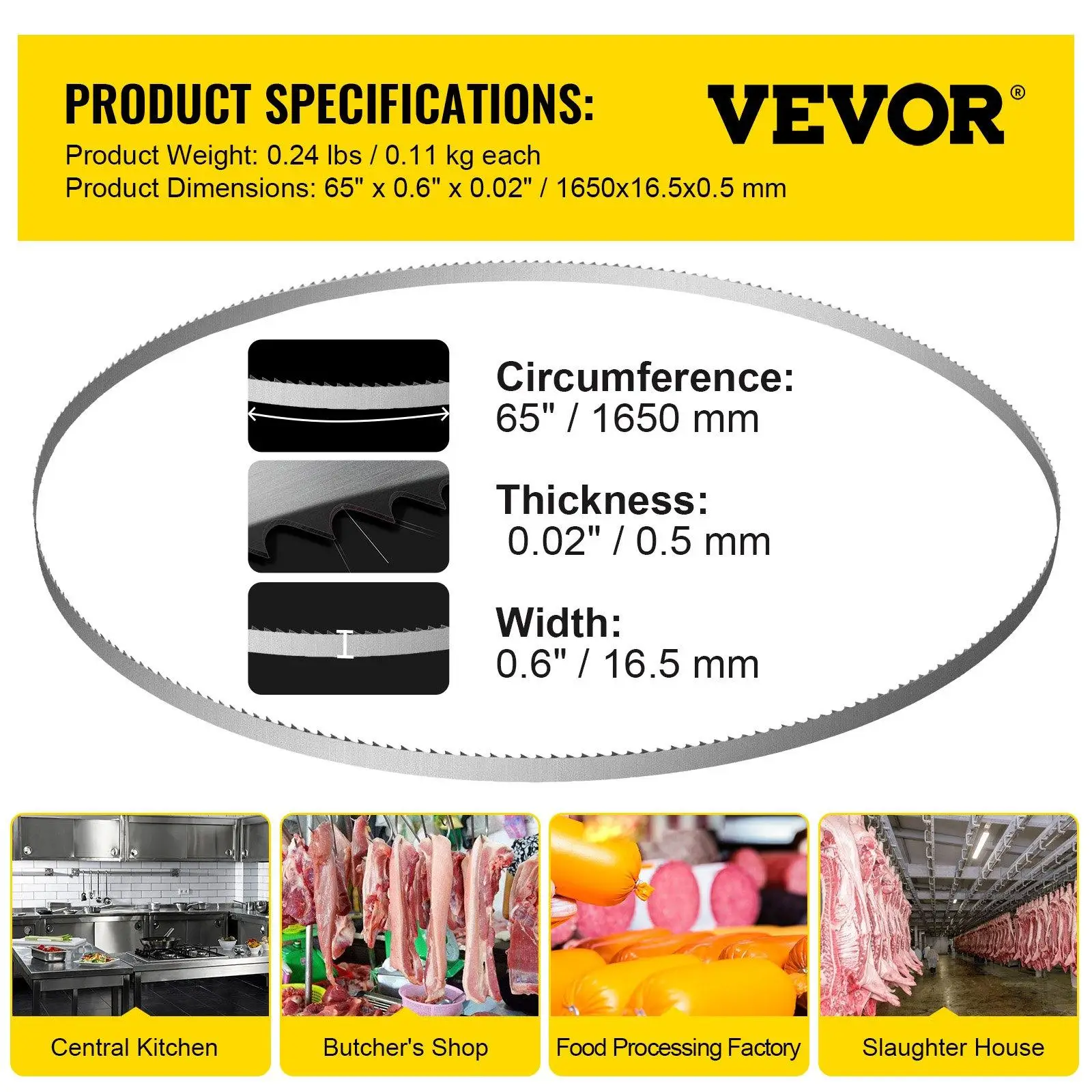

2. Blade Size: The size of the blade is also important. The length and width of the blade will determine the size of the cuts you can make. Choose a blade size that is appropriate for the type and quantity of meat you will be cutting.

3. Teeth Per Inch (TPI): The number of teeth per inch on the blade is another important factor. A higher TPI will provide a smoother, cleaner cut, while a lower TPI will be better for cutting through thicker meat and bone.

4. Blade Thickness: The thickness of the blade also affects the quality of the cut. A thicker blade will be more durable and last longer but may not cut as smoothly as a thinner blade.

5. Blade Shape: The shape of the blade can also affect the quality of the cut. A straight blade is best for general-purpose cutting, while a scalloped blade is better for cutting through bone and frozen meat.

6. Blade Maintenance: Consider the ease of maintaining the blade. Look for a blade that is easy to clean and sharpen and one that will not require frequent replacements.

7. Brand and Quality: Choose a reputable brand that produces high-quality blades. A good blade will last longer and provide a better performance, ultimately saving you money in the long run.

VEVOR Band Saw Blade- The Best For 2023

VEVOR is a brand that offers a range of band saw blades that are designed for various cutting applications. The VEVOR band saw blades are made from high-quality materials, such as carbon steel, high-speed steel, and bi-metal, to provide excellent performance and long-lasting durability.

VEVOR band saw blades are available in various sizes and configurations to fit different types of band saws and cutting tasks. For example, there are blades with different tooth configurations, including regular, skip, and hook, which are designed to cut different types of materials, such as wood, metal, and plastic.

When choosing a VEVOR band saw blade, it is important to consider the material you will be cutting, the thickness of the material, and the type of band saw you have. It is also important to ensure that the blade is properly installed and tensioned to ensure safe and efficient cutting.

Features of the VEVOR Band Saw Blade

Some of the features that are commonly associated with VEVOR Band Saw Blades include:

1. High-quality material: VEVOR Band Saw Blades are typically made from high-quality materials, such as carbon steel or bi-metal, which makes them durable and long-lasting.

2. Versatility: These blades are designed to cut through a wide range of materials, including wood, metal, and plastic.

3. Precision cutting: VEVOR Band Saw Blades are typically designed to deliver precise, clean cuts, thanks to their sharp teeth and precise blade geometry.

4. Durability: These blades are designed to withstand heavy use and high-speed cutting, which makes them ideal for industrial settings.

5. Compatibility: VEVOR Band Saw Blades are compatible with a range of band saw models, so they can be used as replacement blades for many different machines.

6. Affordable: Despite their high quality, VEVOR Band Saw Blades are typically priced competitively, making them a cost-effective option for many users.

How to Use the VEVOR Band Saw Blade

Here are some general steps to follow when using a VEVOR band saw blade:

● Ensure safety: Wear protective gear like safety goggles, gloves, and earplugs to prevent any injuries.

● Install the blade: Install the VEVOR band saw blade according to the manufacturer’s instructions. Ensure that the blade is correctly aligned and properly tensioned.

● Adjust the speed: Adjust the speed of the band saw according to the material you are cutting. The blade’s speed should match the density of the material.

● Position the material: Position the material to be cut on the band saw’s table. Ensure that it is stable and secure.

● Start the band saw: Turn on the band saw and allow the blade to reach the desired speed before starting the cut.

● Begin the cut: Slowly lower the blade onto the material and guide it along the desired cutting line. Use even and steady pressure to ensure a smooth and clean cut.

● Monitor the blade: Watch the blade’s performance during the cut to ensure that it is cutting evenly and smoothly. If the blade begins to wander or cut unevenly, stop the cut, and adjust the blade.

● Complete the cut: Once the cut is complete, turn off the band saw, and remove the material from the table.

● Clean up: Clean the band saw, and store the blade in a safe place for future use.

Always remember to follow the manufacturer’s instructions and safety guidelines when using the VEVOR band saw blade.

FAQs about Band Saw Blade

1. How often Should I clean the meat band saw blade?

It is important to clean the meat band saw blade regularly to maintain its effectiveness and prevent contamination. The frequency of cleaning the blade depends on how often you use it and how much meat you cut.

2. How Do I Adjust the Speed of the meat band saw blade?

The speed of a meat band saw blade can usually be adjusted by changing the pulley settings on the saw’s motor.