Hydraulic jacks are essential tools that help in lifting heavy objects. They utilize the power of hydraulic fluid or oil in lifting the heavy load. Their practicality and functionality give them widespread application across various fields, from agriculture to industries/construction sites to DIYers’ homes and roadsides for emergency auto fixes.

However, regardless of their type or unique specifications, hydraulic jacks have a common mechanism and contain the same fundamental components (cylinder, pump, reservoir for hydraulic fluid/oil, and valve). Consequently, mastering your car’s hydraulic jack needs is straightforward once you grasp the concepts of its significant components—regardless of the type of jack or your vehicle’s model. Additionally, understanding how the parts of hydraulic jacks work and interconnect with one another helps ensure that your unit affords you years of safe and efficient use.

Are you ready to explore the fundamental basics of hydraulic jacks and boost your DIY/professional experience with your automobile hydraulic jacks? You’re going to learn everything you need to know in this straight-to-the-point guide.

Table of contents

Overview of Hydraulic Jacks

What’s the concept of a hydraulic jack really about? Here’s an overview of hydraulic jacks, what they are, how they work, their significant parts, plus other common challenges users could find with the parts in question.

What Are Hydraulic Jacks?

A jack is a mechanical device used to lift heavy objects by applying force via a hydraulic mechanism. While there are other types of hydraulic jacks, hydraulic jacks use fluid/oil to generate the necessary force. Hydraulic fluids help these jacks lift heavier loads more efficiently and capably.

The main components of a hydraulic jack include a pump, a cylinder, and a piston. Once someone operates the pump, pressure mounts within the cylinder and causes the piston to move. Movements in the piston exert force on the object in focus, raising it from the ground.

Hydraulic jacks come in various categories, depending on your vehicle’s range and, of course, your preferences. Popular types of hydraulic car jacks include floor jacks, bottle jacks, scissor jacks, hi-lift jacks, transmission jacks, car stands, and trolley jacks.

How Do Hydraulic Jacks Work?

Let’s run through the basic process hydraulic jacks take in lifting heavy objects. All hydraulic jacks include a hydraulic fluid-filled chamber that contains a hydraulic fluid. A plunger or piston that moves up and down within the chamber (a closed system). Hydraulic jacks exert pressure on the fluid contained in the closed system. Based on Pascal’s principle, the pressure gets transmitted in all directions, magnifying the force to lift the object.

That said, have you ever had to look up a new meal’s ingredients to have a clue about why it tastes the way it does, its nutritional requirements, or how you could reproduce the meal from your kitchen? Maybe the idea isn’t far-fetched from the concept of a hydraulic jack diagram. Just like your favorite dish’s ingredients, a hydraulic jack diagram helps you grasp the device’s entire mechanism.

The typical diagram of a hydraulic jack outlines its key parts, while clearly describing the operating mechanism of a hydraulic jack in a way that almost anyone can understand. Talking about key parts of hydraulic jacks, the next section describes the main parts of all hydraulic jacks, their roles, and typical challenges.

Key Parts for Hydraulic Jacks

Thanks to VEVOR’s series of excellent auto equipment, users can rest assured of high-quality parts in a hydraulic jack when they order one of the brand’s hydraulic jacks. All parts in VEVOR’s hydraulic jacks are made from durable materials that ensure the best usage terms – all to make a stellar hydraulic jack at highly competitive rates. That said, let’s run through the key parts of a hydraulic jack, their roles, and other details worth noting about these significant components.

Hydraulic Cylinder

Hydraulic jack manufacturers like VEVOR build hydraulic cylinders with durable and tough materials to withstand pressure build-up due to the movement of fluid within the piston. Should the cylinder develop any structural fault, the hydraulic jack could collapse and fail to lift, lower, or hold heavy objects.

Common maintenance tips to keep your hydraulic jack cylinder always in shape include regular cleaning/inspection, alongside using the right fluid to avoid quick degradation.

Pump

Hydraulic pumps help to drive hydraulic fluid around the closed system (piston/cylinder) to initiate the necessary mechanical advantage for the desired action. Hydraulic pumps generally operate using the same principle. However, their operation occurs in two basic forms: gear pumps and piston pumps.

Piston pumps further divide into axial and radial pumps, with axial pumps producing linear motion against radial pumps’ rotary motion. On the other side of the coin are gear pumps, subdivided into internal and external gear pumps.

Additionally, all hydraulic pumps (piston and gear), come in either double-action or single-action modes. While single-action pumps only pull, push, or lift in one direction, double-action pumps can pull, push, or lift in multiple directions. The hydraulic pump is at the center of the hydraulic system and practically differentiates hydraulic jacks from other jack types.

To troubleshoot your hydraulic pump for sources of any hitches:

- Check your directional control setting

- Assess whether your pump is receiving fluid

- Assess whether your drive motor isn’t reversed

- Check the pump relief valve

- Check the hydraulic fluid levels

- Assess the pump for any mechanical damage

- Assess whether your drive motor is operating correctly

- Check whether your pump coupling is damaged

Regular maintenance tips for your hydraulic pump include:

- Keeping the suction strainer clean

- Regularly changing hydraulic filters

- Cleaning the pump’s exterior

- Visually inspecting the connections and hose

- Sticking to a regular maintenance routine.

Reservoir

The reservoir in a hydraulic pump stores the hydraulic fluid in the closed system towards moments of pressure change. These reservoirs could come in tough materials like steel to effectively withstand the pressure of fluid motion within the closed system.

Valves

Hydraulic car jack manufacturers use different types of valves in coupling the units like check valves, release valves, control valves, and high-pressure valves.

Check valves are one-way valves that only allow the flow of fluids in one direction as long as flow pressure remains constant while protecting the piping system against reverse flow. Ball, piston, and stop check valves are the three main types of check valves. Control valves help to control fluid flow by altering the size of the flow passage, based on the signaled directions from a controller, while the release valve uses a device (such as a screw) in managing the flow of air throughout the system.

Common problems users have with hydraulic valves include loose fitting or stuck valves. However, with regular inspection, lubrication, and the use of proper hydraulic fluid, users can extend the lifespan of their hydraulic car jack pump’s valve.

Understanding Hydraulic Jack Diagrams

Remember our earlier analogy about your favorite dish and its ingredients? Hydraulic jack parts diagrams are like the cookery book that beautifully describes each condiment, their usage, and how they contribute to the whole palatial delight you crave. Here’s exploring hydraulic jack diagrams and why they’re important in helping you understand your device’s vital parts.

Why Hydraulic Jack Diagrams Are Important

Every professionally crafted hydraulic system began as either a paper schematic or a CAD digital – some form of technical drawing. Such representations detail hydraulic flows, inputs, outputs, and moving parts, besides any other electromechanical components or motors.

Depending on the unique verbiage the architect/engineer employs, the diagram represents the hydraulic mechanism and parts using a fixed set of symbols, colored lines, and other designated elements to effectively communicate the idea.

Meanwhile, the main advantage of having a physical plan for your hydraulic system is that it makes it easier to troubleshoot, repair, or modify the different parts should any faults arise. That’s because locating any missing, broken, or malfunctioning items becomes easier once there’s a hydraulic diagram.

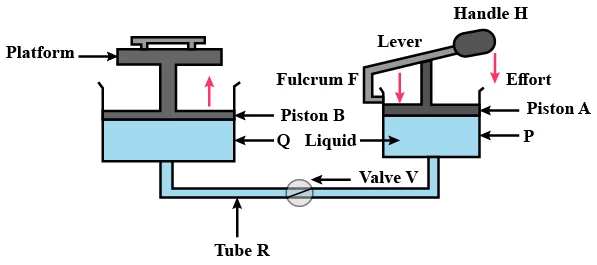

Diagram of a Hydraulic Jack: A Visual Guide

The above figure represents and labels key parts of a hydraulic jack. The actual expressions might differ from one model to another, but the principles are largely the same in all hydraulic car jacks.

Pressing handle H of the lever by applying an effort opens valve V, thanks to an increase in the pressure at cylinder P. Hydraulic fluid runs out from cylinder P to cylinder Q. Consequently, the piston B rises and raises the vehicle or car placed on the jack’s platform.

The operator stops pressing the handle H of the lever once the car reaches the desired height. That closes valve V (as the pressures on either side of the valve become equal) to prevent the liquid from running back from cylinder Q to cylinder P.

Common Issues Identified Through Diagrams

Thanks to hydraulic symbolism, operators, technicians, and engineers can modify and mark changes and faults quickly in a way that everyone else can easily understand. Without a hydraulic floor jack parts diagram, for instance, engineers may have to disassemble a floor jack to analyze its complex parts – which wastes time and money while risking potential contamination and human error over contact.

Suppose a valve develops some fault, engineers can leverage the hydraulic jack diagram by knowing exactly where to tinker or manipulate to resolve the challenge. That said, technical drawings go beyond just aiding repairs to allow machine owners to create effective maintenance plans that highlight key areas of the hydraulic circuit with a reasonable probability of degrading or failing.

Maintenance Tips for Hydraulic Jacks

Your hydraulic jack needs regular maintenance over time to keep the various hydraulic components up and running for longer. This subsection details some daily, weekly, and annual maintenance routines to always keep your hydraulic car jack in shape. Consider checking the manufacturer’s manual or other standard maintenance manuals for further detailed guidance on sustaining your hydraulic car jack’s health.

Routine Maintenance for Longevity

Here are some routine maintenance tips to maintain your hydraulic jack’s health.

Daily/Weekly maintenance tasks

- Check the oil levels

- Check for temperature changes in the oil

- Check the system for water or dirt in the oil

- Check for leaks

- Check and tighten screws and pipe clamps

- Verify pressure gauge readings

- Empty all valve panel drip pans

- Monitor the running noise of lumps and electric motors to identify changes

- Check for possible leaks in the valve

- Keep all surfaces clean

- Check air filters

- Check the service book (when in organizations or workplaces) to see if operators recorded any problems

Monthly/Periodic Tasks (4-6 weeks, or more)

- Check air filters

- Check and clean the strainer in the cooling water pipe.

- Clean the hydraulic power unit and check for possible leaks

- Replace fittings that kept leaking after inspection and tightening

- Assess the condition of hydraulic hoses.

- Check the condition of all hydraulic cylinders, removing any dirt from the rod pivots.

- Tighten pipe clamps, if necessary

- Tighten bolts on pumps, valves, and electric motors

- Periodically send an oil sample

Annually, check the hydraulic jack to see if it requires servicing with the manufacturer or a certified engineer, or replacement. Meanwhile, using the right hydraulic fluid helps your jack to prevent the internal components from quickly degrading and prolonging the unit’s lifespan.

Troubleshooting Common Problems

Are you facing common hydraulic jack problems like leaking hydraulic fluids or seeing your jack failing to lift properly off the floor? You should find the next couple of paragraphs handy.

Leaking Hydraulic Fluid

Your car jack’s hydraulic oil can leak internally and externally due to various reasons like damaged seals, inappropriate fittings, or corroded metal parts. Visually assess the unit for any external leaks. Where necessary, replace the damaged seals/o-rings and the fittings by purchasing a hydraulic jack rebuild kit. Thankfully, the solution to a leaking jack could be as straightforward as tightening the bolt at one of the pistons to tighten the seal and correct your leak.

Jack Not Lifting Properly

Is your car’s hydraulic jack not lifting properly? Common reasons for such challenges include lubrication, overloading, or an unusually low/high hydraulic fluid level in the reservoir. First, ensure that you’re not placing a load on the hydraulic jack that’s higher than the specified lifting capacity.

Once you’ve resolved that the hydraulic jack isn’t being overloaded, follow the next steps in an attempt to revamp a hydraulic lift that won’t lift:

- Place the hydraulic jack on a stable and level surface

- Check the release valve for any signs of damage, corrosion, or blockage

- Assess the hydraulic oil level to see whether it’s too low (or possibly high)

- Adjust the hydraulic fluid to the right level based on the manufacturer’s information

If your car’s hydraulic jack’s level still won’t get off the ground after pulling the pulley, perhaps you need to consult with qualified personnel to help you fix it.

Conclusion

Hydraulic jacks are one of the most valuable tools for car owners and professional repairers. Car owners need them for DIY emergency repairs/routine checks, while professional repairers need them to carry out any of their numerous car repair duties. However, regardless of the hydraulic car jack model or specification you’re working with. Purchasing quality products from a brand like VEVOR, which offers affordable and high-quality parts for hydraulic jacks alongside outstanding customer service can help you to ensure your safety and efficiency.

Every item you purchase from VEVOR comes with a 12-month hassle-free warranty offer plus a return clause if the delivered product falls short of your expectations. Visit VEVOR today for the best hydraulic jack parts and accessories for a more convenient, efficient, and lasting experience with your lifting needs.