Most woodworkers’ and contractors’ garages have a table saw to work on. It’s the most powerful tool that seems simple, but table saw parts can confuse you. Understanding table saw parts is essential for safety and efficiency in woodworking projects. They’re commonly used in many woodworking shops, e.g., furniture shops. But if not used correctly, it can be dangerous. Woodworkers can safely minimize their productivity and achieve their desired results after learning table saw components and how they function.

Which brand table saw parts and functions are up to work? The table saw market is diversified; not all brands, like VEVOR table saw, provide top-notch features. With VEVOR table saw parts, you get high security as this is designed with a security shield. A table saw blade prevents the machine from slipping out if it gets heated, and overload protection prevents damage. Learn more details about table saw parts to save yourself from any inconvenience.

Table of contents

Different Types of Table Saws

According to different features and specifications, there are various types of table saws available:

- Contractor

- Benchtop

- Portable

- Hybrid

- Cabinet:

Let’s start up with a contractor table saw…

Contractor Table Saw

Contract table saws are larger and heavier than benchtop saws but more mobile. Professionals and home workshops use them. They provide stability and power and are suitable for large hardwood projects.

Benchtop Table Saw

With an enthusiastic mind, benchtops are designed. They’re affordable and lightweight. Hobbyists and DIYers prioritize this tool. They make the perfect fit if you’re a beginner and don’t know how to use a table saw. Get a benchtop table saw to make your first spice rack or bookshelves. They’re tailored to your needs and comprise lightweight materials containing multiple composites. These models don’t come with a stand to move them around.

Furthermore, 50 Lbs is not something to worry about for an average person. They’re equipped with direct-drive motors but not very durable. But they provide good power according to their size.

Portable Table Saw

The portable table saw design makes them easily transported, usually with folding wheels and stands. They’re popular among professionals, enthusiasts, and hobbyists due to their lightweight and easy-to-transport features. However, they may lack power and durability compared to larger models, they provide convenience and flexibility.

Hybrid Table Saw

A hybrid table saw has the combined features of a cabinet and contractor table saw. They offer power balance, affordability, and excellent performance. Usually, they have a compact design and lighter construction than cabinet saws. Hybrid saws are an outstanding choice for woodworkers who seek cabinet saw-like performance without a high price tag.

Cabinet Table Saw

A cabinet saw is the dream of every woodworker. You can find them in high-level workshops and factories. Hobbyists like to have them, but it’s a single-phase model. Enthusiasts don’t run the three-phase machine. They offer solid construction and are known best according to the built-in structure.

A cabinet table saw is a durable device of steel and cast iron. Suitable to perform high-duty cycles as they build up to last. They don’t vibrate while working, and it’s a common issue with cheap models. Moreover, they improve accuracy when making a compound cut or standard ripping.

VEVOR offers a wide range of table saws like benchtops, contractor saws, portable saw, etc. Due to these saws, contractors, professionals, and enthusiasts enjoy performance, convenience, and efficiency. Featuring portability, construction, safety, and quality, the VEVOR table saw was built to meet the needs and is valuable for money.

The Heart of the Machine: The Table Saw Blade

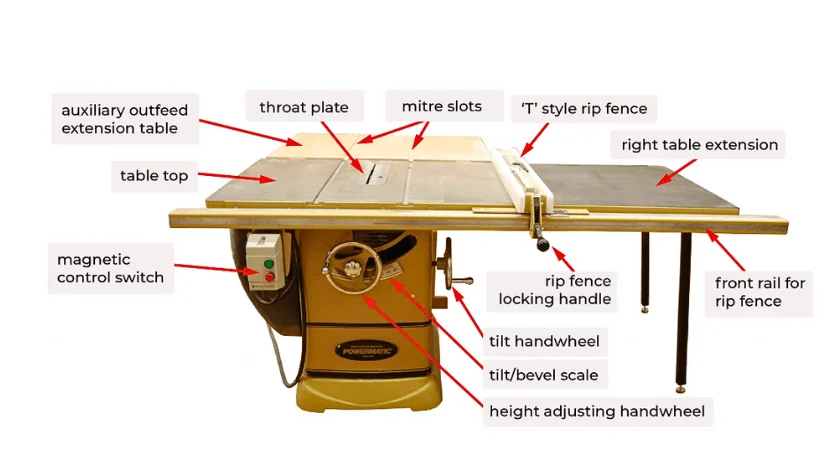

The table saw blade comes in different types and sizes and cuts the workpiece as per your choice. It’s essential to use the table saw blade with the right size to prevent yourself from any injury or damaging the machine. After gathering the right table saw blade, evaluate the teeth number, blade material, and teeth geometry to use. Take a look at the table saw part diagram:

You can select the table saw blade of your choice according to the type:

Crosscut Blade: These blades are ideal for cutting wood grain, and their multiple teeth provide smooth and splinter-free cuts.

Rip Blades: They are used for cutting wood and have fewer teeth with enormous gullets to move materials quickly.

Combination Blades: These blades are versatile; they handle both cross and rip cuts efficiently. They provide a balance between finishing quality and speed.

Diameter: Table saw blade standard sizes in blades range from 8-12 inches. The blade size affects the capacity and depth of cutting of a saw.

Arbor Size: The blade arbor size matches your table saw arbor size. The common arbor sizes are from 5/8 to 1 inch.

Width: The cut width created by blades, known as kerf, depends upon blade design and type. Using thin-kerf blades minimizes waste during durability and strength.

The VEVOR table saw blades are dedicated to providing woodworkers with precise, versatile, and trustworthy cutting tools. Whether a DIY enthusiast or a professional craftsman, VEVOR table saw blades provide the efficiency and precision you need.

The Throat Plate: A Closer Look

The table saw throat plate supports the workpiece, maintains blade clearance, and ensures safe and accurate cutting. For high-quality cuts in woodworking projects, thorough adjustment and maintenance are required.

High-quality material and precision engineering VEVOR throat plate design make it durable, and precision engineering provides reliable performance and accuracy.

A throat plate covers a table saw blade opening in a table saw. It is used for all cutting operations and is usually made of aluminum and phenolic resin. When aluminum touches the carbide teeth of the saw blade, it will not damage them.

The Arbor: Holding It All Together

An arbor is a shaft on a table saw that holds blades and specifies the blade size you need to use. Many arbors are adjustable in size, but not all of them. A belt or gear work is directly connected to the arbor. The most common arbor sizes are from 1/4 to 1 in diameter, with 5/8 and 1. VEVOR table saw’s sturdy arbor design offers woodworkers the stability, accuracy, and efficiency needed to tackle various cutting tasks easily and confidently.

Elevation and Tilt Handles/Wheels

With tilt handles and blades, you can raise or lower the blade and easily tilt it. Blade tilting offers you bavel cuts, but this means you can’t use narrow plates while doing this. Larger table saws have wheels, while smaller table saw models use handles.

However, with a well-designed table saw handles and wheels, VEVOR provides comfort to its user while operating it. You get an enjoyable process whether using it at a workshop or home.

Safety First: Blade Guard and Riving Knife

The table saw blade guard protects the operator from getting injured while doing the work. Furthermore, it shields the smallest particles and sawdust from the worker’s face. The table saw consists of two blade guards. The first one is attached to a table saw trunnion. This blade guard component is made up of a splitter, guard, and receiving knife and offers anti-kickback fingers sometimes. This type of guard is included with a machine.

The second is an armed guard that usually attaches to a table saw extension. You can buy this guard from the market if the original one needs to be included. They’re easy to adjust according to different cut heights and consist of dust collection. But they don’t compromise anti-kickback fingers or splitters, so you can install them to overprotect the arm guard.

Keeping It Clean: Dust Collection System

While doing a job, any feature that removes dust from the table saw is part of the dust collector usually, blade guards are equipped with this feature. You can attach a voc hose to the port present at the top of the blade guard, enabling you to suck out dust while cutting. This is an incredible dust collection feature of table saw parts whose efficiency depends upon the flow rate and the vac power.

However, VEVOR’s high-performance dust collection features are essential for any workshop, enhancing cleanliness, air quality, safety, and productivity. Investing in a VEVOR table saw dust collection tool improves your productivity.

Additional Essential Components

The other essential components of the VEVOR table saw also increased productivity, which is as follows:

Rip Fence: A vital table saw accessory is a rip fence, but nowadays, many models come with a single one. It allows you to feed the pieces straight into the blade. It’s made of metal, handles the pressure cut, and is sometimes painted with anti-stick paint to facilitate sliding.

Miter Guage: A miter guage has a similar function to a fence but looks different. These miter gauges consist of metal and plastic and change the straight edge degrees to get straight and precise cuts.

Push Stick: Push sticks allow you to insert the workpiece into the blade without worrying about your fingers. These are used for creating inner rip cuts and ensuring control over the smaller objects without touching the blade with your fingers.

Bevel Angle Guage: A measurement tool determines the bevel angle cut on woodworking devices such as table, circular, and miter saws. This device looks like a ruler with a degree scale.

Table Saw Stand: It’s a support structure designed to support a table saw for an efficient job. Table saw stands come in various sizes and designs, including folding, cabinet-style, etc. With a table saw tabletop, workers perform their tasks comfortably.

Summing Up

Now, the confusing topic is straightforward after breaking down parts of table saw into various parts and features. Only a few concepts are available about the table saw, which has been cleaned now. Visit the VEVOR website to explore different ranges of table saws available and take advantage of special offers and promotions. With VEVOR experience, woodworking is at its best- the performance you expect.