The plasma cutter is one of the most interesting and powerful tools developed in the 20th century. Power plasma cutters are excellent options for home DIY jobs and light-duty small business projects.

What is Plasma Cutting?

Plasma is the utilization of electricity to expend an ionized gas through space to create heat. Now, plasma cutting is utilizing this heat_plasma (the fourth stage of matter)-to come up to a temperature that will cut directly through metals.

What Can You Do With a Plasma Cutter?

A plasma cutter is an effective way to cut metal quickly and efficiently. It is the preferred method for automotive repair, structural steel fabrication, and construction companies, widely used in large-scale projects to cut and fabricate huge beams or metal-sheet goods.

Apart from regular scenarios, plasma cutters have other unique uses. For example,

locksmiths use plasma cutters to bore into safes and vaults when customers have been locked out. Plasma’s ability to cut any conductive material allows scrap yards and recycling services to process metal. Artists and metal workers use handheld cutters to create unique works of art that would never be possible with conventional metal-working tools. This single tool gives users the ability to bevel cuts, bore precise holes, and cut in just about any way they can conceive. The plasma cutter performs with distinct advantages.

VEVOR, as a professional tools and equipment retailer, is experienced in the field of welding products. VEVOR plasma cutter is an all-in-one machine, dust-proof and water-resistant. It features precisely measured fan for effective heat dissipation (30%@40°C). No misleading labeling, with an ideal clean cut of 1/2″ (12.7 mm) and a maximum cutting thickness of 5/8″ (16 mm) to meet most daily needs. Safer and more convenient for home DIY or beginners.

What Can a Plasma Cutter Cut Through?

Plasma cutting works best with conductive materials, perfect for cutting cast iron along with steel, copper, and other conductive metal.

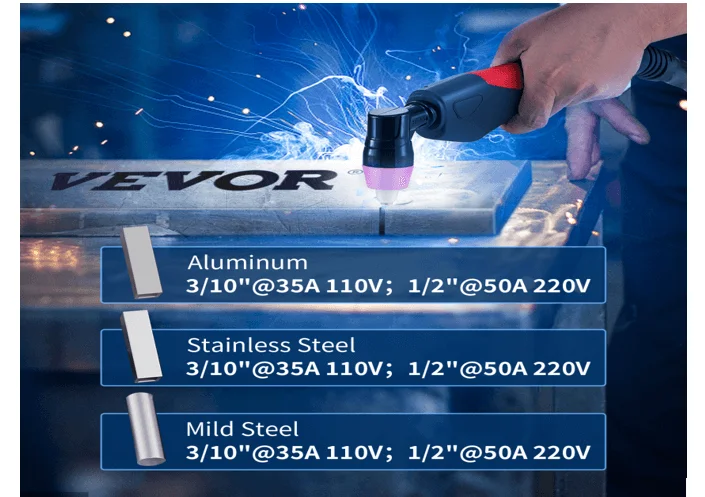

VEVOR specifically designed cutting parameters for different metal materials, e.g., Aluminum: 3/10 “@35A 110V; 1/2 “@50A 220V. You can easily store your cables and accessories with two cable racks. Light weight and a comfortable handle make it easy to carry. Added USB (output: 5V/1A) interface can power connected USB devices like desk fans and USB lights.

This multifunctional plasma cutting machine is perfect for industrial/construction work and home/hobby use. It can also be used to create artistic patterns on metals. VEVOR, a professional tools and equipment retailer, is trustworthy with quality service.

How do plasma cutting systems work with gas?

Plasma systems work by utilizing compressed air or compressed gases, such as nitrogen, to ionize to create plasma. Typically these gases are fed through the back of the machine, go into the systems, and then when they make contact with electrode, they ionize and create more pressure. As soon as they build pressure and ionize, they push out a stream, or column, of pure plasma. At its finest point, it is hot enough to cut directly through materials.

How does a plasma cutting torch work?

The torch holds the consumable electrodes housed inside the retention cup, where the gas ionizes and is heated to plasma. The cutting tip constricts the flow to create more pressure through its orifice for the plasma to pass through. As the arc passes through the cutting tip, it forms a focused column of superheated plasma that increases velocity of the arc. For more information about plasma cutting, check out the resource section at vevor.com.