Winches are mechanical tools used to pull a rope in, out, or alter its tension. They are designed to move big weights that are too heavy for most people to move on their own. Additionally, there are different types of winches made for diverse uses, such as hydraulic, manual, air, and worm. This guide will help you understand different winch kinds and their best industrial uses.

Table of contents

Exploring the Different Types of Winches

There are several ways to power winches, including electric and hydraulic power. Other winches can be hauled by manpower as well. Let’s explore types of winches and their uses.

Hydraulic Winches: Powerhouses for Heavy Duty

A hydraulic system provides power to a hydraulic winch. The winch needs a hydraulic pump to run. A hydraulic winch is more powerful and long-lasting than any other. A hydraulic winch has the strength and durability to tackle a large task.

It is essential for almost any other large task, as it provides strong durability and heavy-duty functionality. There is no way to quantify the increased strength and efficiency that come with installing a hydraulic winch, but it will require additional parts to operate. For example, a tow truck, would need a hydraulic winch and use an integrated hydraulic pump system to operate the heavy-duty winch.

How do they work?

A basic hydraulic winch needs fluid, usually oil. It makes use of fluid power by connecting the generator and the machine with a motor pump and hydraulic system. The pressure generated by the power steering pump transfers power through the pressure within the oil.

When a motor is insufficient to do a heavy task, a gearbox might finish the winch. Cables that support the load are connected to the winch via gearboxes. The motor of a winch typically has no speed settings. The gearbox lets you employ specific speeds for your job because you cannot alter the speed.

Common uses: Industrial applications and heavy-duty recovery

Pros:

- Immense power

- Precise control

- Long-lasting

- Continuous working capacity

Cons:

- Complex

- Expensive

- Requires hydraulic setup

Electric Winches: Versatile and User-Friendly

Electric winches use electric power to work. Compared to manual hoists, electric hoists can raise more weight, but they heat up more quickly when in use. You should select a winch model with a greater pulling capacity than what you want in order to prevent the winch from overheating.

These motorized winches provide solutions for basic jobs like opening doors and hatches or turning on chandeliers while doing maintenance.

How do they work?

Electric winches are mechanical tools that run on electricity. A wire rope length is wound in or out of the device via a drum. A stopper secures the wire rope at its end as it spools around the drum.

Electric motors are used in electric winches to drive or power the drum that works to wind wire. Usually, the motors may be adjusted to accommodate higher loads, and some even feature gears that allow them to haul up extremely heavy items. These electric winches have simple gears that function similarly to push bike gears.

Common uses: Hauling vehicles, boats, trailers, and DIY projects.

Pros:

- Easy to use

- Portable

- Multiple mounting options

Cons:

- Limited power compared to hydraulic

- Battery-dependent

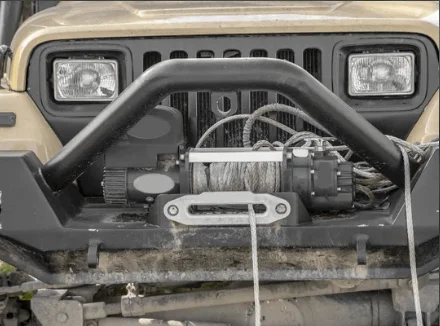

VEVOR Electric Winches: A Cut Above

When looking for a reliable electric winch, VEVOR’s Truck Winch stands out among the competition. The winch boasts a load capacity of 13,000 lbs and a 4.6 KW motor with a 265:1 gear ratio.

Its powerful motor is connected to a 3-stage planetary gear system that provides strong pulling power and faster speeds. This makes it suitable for cars, boats, trucks, jeeps, modified vehicles, and utility trailers.

The electric winch comes with an 80 ft long synthetic rope for quickly rescuing vehicles stuck in the mud. The winch includes a high-precision wireless remote control for easy operation in any terrain or weather and also features a one-handed controller.

The truck winch includes a precise wireless remote control and a one-handed controller for easy operation, unaffected by terrain or weather. It comes with an electric winch, hawse fairlead, wireless and wired remote controllers, a hook, and bolts. This winch is perfect for off-roading adventures, ATV recovery, rough terrain, loading boats, heavy lifting, fishing, and roadside assistance.

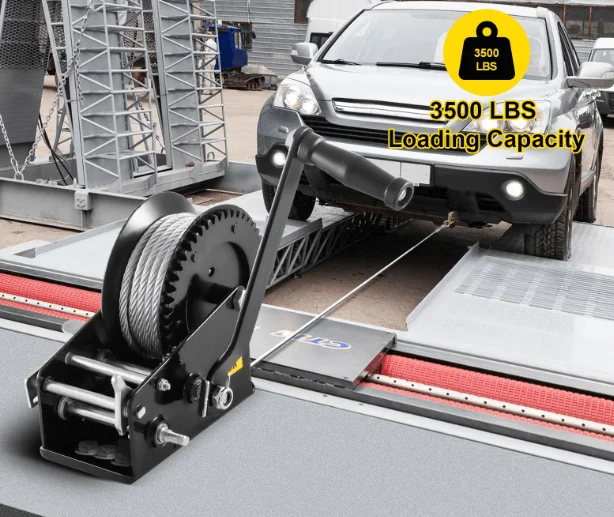

Manual Winches: Simple, Reliable, and Affordable

Manual winches require manpower, so their operation depends on human labor. Depending on the required action, the person in charge turns the handle to wind the cable in or out.

Since hand winches are frequently small and lightweight, they can be used in a variety of settings where a powered winch or other lifting apparatus may not be practical or available.

How do they work?

A manual winch is a mechanical device that is physically driven and used to lift, pull, and carry heavy loads or items. It is made up of a handle, a gear mechanism, and a drum or spool. The gear mechanism interacts with the drum when the user rotates the handle to wind or unwind a cable. Depending on the application, this motion enables the hand winch to either raise a cargo or draw it closer or farther away.

Common uses: Light-duty tasks, emergencies, and load handling in limited spaces.

Pros:

- Inexpensive

- No external power needed

- Easy to maintain

Cons:

- Slow

- Limited power

- Physically demanding for heavy loads

Air Winches (or Pneumatic Winches): Compressed Air Power

Compressed air is the power source for air winches. They are less popular than electric winches, but they offer some unique benefits that make them perfect for specific applications. Being able to use air winches in explosive conditions is one of their biggest benefits.

Electric winches are not a good option for environments where sparks or electrical failures could be problematic. However, because they are pneumatic, air winches remove this risk and are frequently utilized in sectors of the economy where worker safety is of the utmost importance.

How do they work?

Compressed air power is used to spin a drum; winding or unwinding the rope or cable. The fan motor delivers compressed air to drive the mechanical components of the winch. The drum either raises or lowers the weight, depending on which way the drum is rotating.

Common uses: Industrial settings where sparks are a concern.

Pros:

- Spark-free operation

- Safe in hazardous environments

- Precise load control

- Compact and lightweight

Cons:

- Requires an air compressor

- Less common than other types

Worm Gear Winches: Self-Locking Security

The Worm gear winch can be the best choice if you’re searching for a portable winch that can assist you with heavy lifting. A mechanical winch device is employed to haul large weights.

This robust device features a drum attached to a worn shaft and worm gear. The entire mechanism is supported by a ball and thrust bearing for smooth operation. Hand winch devices are lightweight and can be mounted both on the wall and on foot.

How do they work?

The main controls for this equipment are usually in the form of a three-way joystick that can allow the operator to (de)snub the rope in or out while maintaining precise control over the other operations.

Pulling the joystick handle back also draws more rope up thus enabling the object to be lifted away as it is being pulled up. You can push the handle forward to lower the object. It is specially designed for heavy loads with an anti-slip designed for load stability.

Common uses: Lifting, lowering, and holding heavy loads.

Pros:

- High holding power

- Ideal for safety-critical applications

Cons:

- Slower line speed

- Not designed for high-speed pulling

Choosing Your Ideal Winch: Key Considerations

When selecting the ideal winch for your needs, several key considerations can help ensure you make the right choice.

Line Pull Capacity (How much weight do you need to move?)

Firstly, you need to determine the line pull capacity, which refers to the maximum weight that the winch can effectively move. You can calculate this by considering the weight of the load you may expect to move.

It’s crucial to choose a winch with a line pull capacity that exceeds the weight of your heaviest anticipated load to ensure safe and efficient operation.

Line Speed (How quickly do you need to move the load?)

Line speed is another important factor to consider. This refers to how quickly the winch can pull the load. There is often a trade-off between speed and power, as higher speeds may sacrifice pulling power and vice versa.

You must consider your specific needs and whether speed or power is more important for your applications.

Power Source (Electricity, hydraulics, manual, or air?)

Lastly, you must consider the power source that drives the winch. Winches can be powered by electricity, hydraulics, manual operation, or air. You need to choose a power source that matches your application and available resources.

Electric winches are common and suitable for most applications, while hydraulic winches offer high pulling power but require hydraulic systems in the vehicle. Manual winches are portable but require physical effort to operate, while air winches are suitable for industrial applications but require compressed air sources. So, it’s up to you which one you’ll need for your task.

FAQs About Types of Winch

What’s the difference between electric and hydraulic winches?

Winches that are electric or hydraulic each have advantages as well as disadvantages. The way they are powered is the primary difference between the two despite the fact that they both operate on the same concept.

Electric winches are the most preferred option among do-it-yourselfers and off-road enthusiasts. They’re a great addition to cars without an integrated hydraulic system because they run on electricity. However, an excellent addition to any kind of off-road vehicle is a hydraulic winch. It can make any kind of pulling work much safer and easier to perform because it is strong and dependable.

Which type of winch is best for off-roading?

There are a few things to take into account while selecting a winch for your off-road travels. The kind of rope that is utilized is one crucial element. Steel cable is heavier and more difficult to handle than synthetic rope, although synthetic rope might not be as strong. The winch’s pulling force should also be taken into account. Make sure the winch you select has adequate pulling force for the weight of your car.

Are electric winches safe to use?

Although an electric winch is a really helpful tool, there are a few important considerations to make sure you’re operating it safely. It is crucial that these electrical hoists are operated properly and that everyone on the site is knowledgeable about what they are doing as they lift such large loads.

What should I look for when buying a winch?

You must think about the weight capacity of the winch. It establishes the highest load that the winch can securely support. Compute the combined weight of the cargo, vehicle, or equipment you plan to tow in order to determine the proper weight capacity. To provide yourself a safety buffer, it is recommended that you select a winch whose capacity is greater than this weight.

Conclusion

It could be challenging to sort through the various winch options and choose the one that would be most useful to you. You may make your decision-making process easier by learning how to distinguish between the various kinds of winches with the help of this blog. You are also welcome to do your own research before choosing the right winch for your needs. If you still can’t make a choice, we have the best one for you: VEVOR’s heavy-duty winch. You can find its features on the VEVOR website.