Are you in the market for a refrigerant recovery tank, and the choices seem to be many? Fret Not; we got you!

Refrigerant recovery tanks are a crucial tool for anyone working with HVAC systems. These tanks are designed to recover and store refrigerant gases safely and efficiently. However, with so many different models, materials, and sizes on the market, it can be overwhelming to choose the right one for your needs. A refrigerant recovery tank is a solution to your problem as it successfully recovers the refrigerants before repairing or cleaning the electrical appliances. In order to run coolers, refrigerators, and air conditioners efficiently, refrigerants are required.

Whether you’re a professional technician or a DIY enthusiast, having the right refrigerant recovery tank is crucial for maintaining your HVAC systems. So, let’s get started and find the perfect one for you!

Top 5 Refrigerant Recovery Tanks

In this article, we will discuss some of the best refrigerant recovery machines available today. Our “Buying Guide” also contains details such as major features and options that can help you differentiate between them. This will allow you to select the most suitable refrigerant recovery machine for your application.

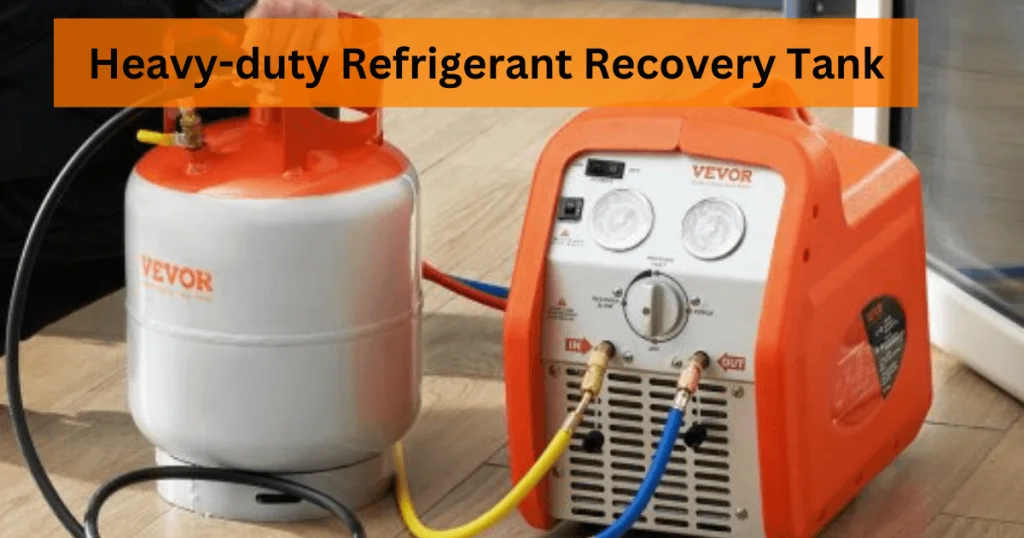

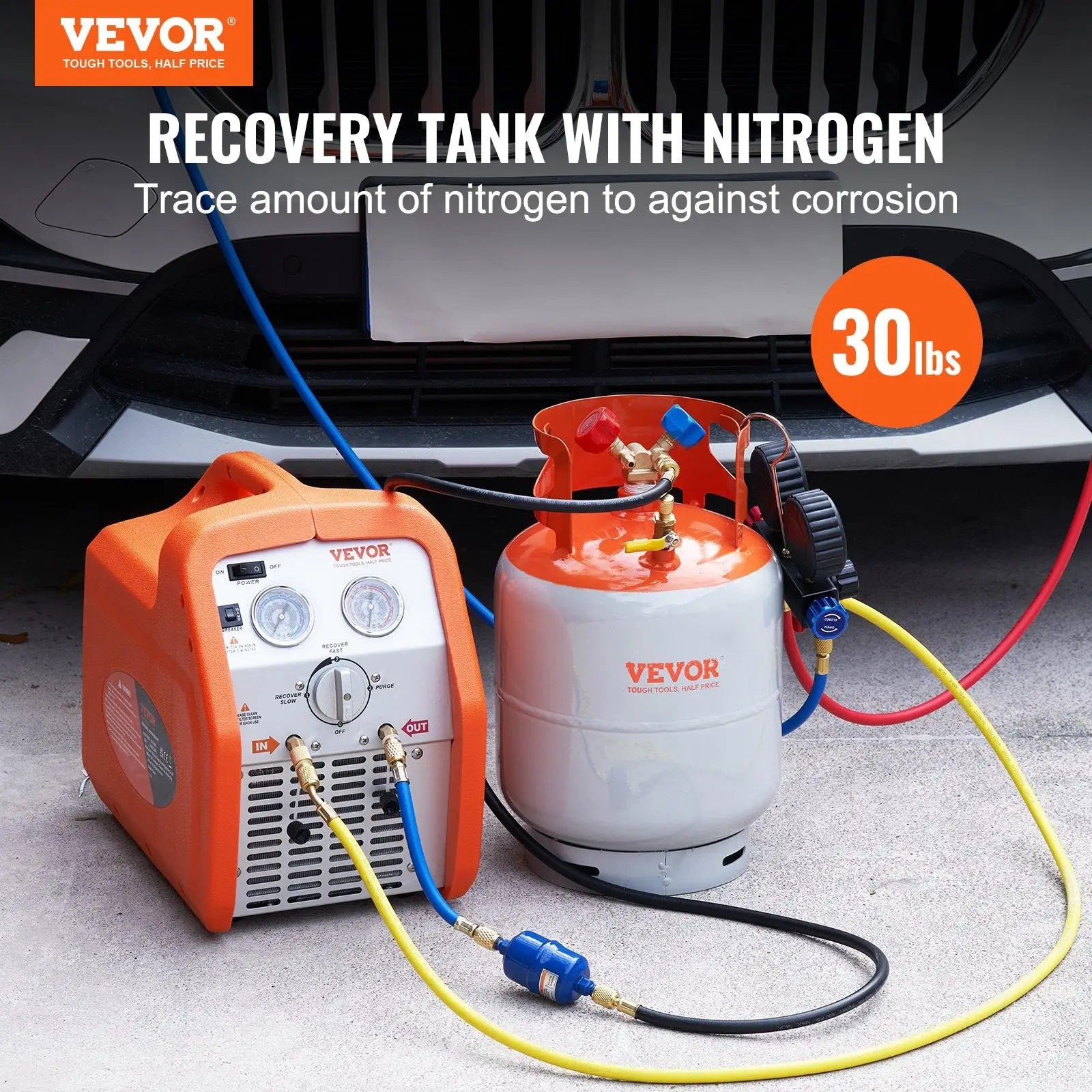

1- VEVOR Refrigerant30lb Cylinder Tank Recovery Reclaim Liquid Rated Y Valve 400 PSI

With unparalleled durability and compatibility, VEVOR refrigerant recovery tank can handle a wide range of refrigerants, making it a versatile option for household vehicles and beyond. Equipped with a strong sealing Y-valve and a pressure relief valve, it ensures a safe and secure refrigerant recovery experience, even under high pressure.

The tank body is crafted from durable HP295 steel with a high gloss powder coating and reinforced steel seal, making it resistant to wear even after extended use. And with its reusable design, it’s a cost-effective option for all your refrigerant recovery needs.

Performance and Features

● VEVOR refrigerant recovery tank withstands high pressure up to 400 psi.

● The tank is pre-filled with nitrogen to prevent corrosion and has undergone rigorous pressure tests.

● 1/4″ SAE interface valve with 2 1/4″ SAE to 1/2″ ACME brass adapters for strong compatibility.

● Integral forming brass Y-valve with strong sealing capabilities prevents leakage and efficiently recovers and discharges liquid and steam.

● Includes pressure relief valve for added safety in case of high pressure.

● 30 lb capacity suitable for household vehicles and can handle a range of refrigerants.

● Tank body crafted from durable HP295 steel with a 0.1-inch wall thickness and high gloss powder coating.

● Reinforced steel seal makes it resistant to wear even after extended use.

● Reusable and versatile for a variety of refrigerant recovery needs.

Pros

● Reusable for multiple refrigerant recoverytank needs, making it a cost-effective option in the long run.

● It is a durable and reliable option.

● Brass Y-valve with strong sealing capabilities to prevent leakage.

● Economical.

2- MASTERCOOL 62010 Refrigerant recovery tank 30 lb

This is the ultimate solution for efficient and easy refrigerant recovery. With a compact and portable design, this refrigerant recovery tank machine is perfect for on-the-go use and storage. Equipped with a high-performance compressor and 1/4″ fittings, it can handle both liquid and vapor refrigerants for added versatility. The self-purging feature eliminates the need for manual maintenance, making it a hassle-free option for both beginners and professionals alike.

Performance and Features

● 30 LB DOT Tank

● Y valve for vapor and liquid.

● Compact and portable design for easy transportation and storage.

● It can handle both liquid and vapor refrigerants.

● Reusable.

● High-performance compressor for a speedy recovery.

● Self-purging feature for easy maintenance.

● 1/4″ fittings for connecting to most hoses.

Pros:

● Fast and efficient refrigerant recovery.

● Easy to use, even for beginners.

● Lightweight and compact, making it convenient for on-the-go use.

● No need for manual maintenance.

Cons

● Doesn’t hold a vacuum

3- Automoris Refrigerant recovery tank, 30 LBS Capacity,4 Gal 435 Psi Portable Cylinder

This recovery machine refrigerant tank is suitable for use in a variety of settings, including factories, laboratories, and commercial air conditioning and refrigerator manufacturing. Its thick steel design ensures long-lasting durability, and the -20~55℃ control allows for safe operation in various environments.

Performance and Features

● 1/4 Brass Y-Valve-Flexible Double Valve for easy linking and efficient operation.

● Durable-Thicken & Steel construction to withstand corrosion and deformation.

● Explosion-proof and brass blow-off valve for improved security and quality.

● 30 LBS Volume 4 Gal to securely store refrigerants away from contamination

● -20~55℃ Control for strict temperature limitations during operation.

● Application and Operation in factories, laboratories, homes, etc.

Pros

● Versatile recovery machine refrigerant suitable for multiple kinds of refrigerants.

● Durable welded steel construction ensures long-lasting durability.

● Explosion-proof and brass blow-off valves improve security and quality.

Cons

● Security valve works at a lower pressure

4- Robinair RG6 Recovery Machine Refrigerant

The Robinair RG6 recovery refrigerant unit is the RG3’s successor, with a few more features and quicker recovery rates. At roughly 28 lbs, the device is small and lightweight. It is a very useful and efficient piece of equipment for technicians at an affordable price. The large fan and condensers aid in achieving exceptional cooling swiftly. There is also a self-purge function on the device.

Performance and Features

● Compact and lightweight design for easy portability.

● Compatible with all common refrigerants, including R-410A.

● Recovers liquid as well as vapor.

● Features a cross-flow design.

● Equipped with a high-pressure safety shut-off switch to prevent accidents.

Pros

● Strong, well-built, and quick recovery rates.

● It is effective across both vapor and liquids

● Most common refrigerants are recovered.

Cons

● No oil separator

5- YSNR501 Flame King Refrigerant recovery cylinder Tank 50 Pound

The Flame King YSNR501 Refrigerant recovery cylinder is a top-of-the-line product designed to effectively and safely recover refrigerants. This high-quality tank is a must-have for anyone in the HVAC industry or for those who require refrigerant recovery services. With a durable construction and easy-to-use features, this product is sure to exceed your expectations.

Performance and Features

● The cylinder of the product is coated with powder to give a durable and high-gloss finish. It has a capacity of 50 pounds.

● It features a Y-valve that allows the handling of both liquid and vapor forms of refrigerants.

● It has a 3/4 inches NPT opening that accepts an 80 percent fill float switch shut-off device.

● The product is designed with a collar for easy handling.

● The product is reusable and meets the DOT-4BA-400 specifications and ARI guidelines.

Pros

● Lightweight and portable.

● Works with various refrigerants.

● High-speed recovery.

● Durable and corrosion-resistant construction.

● It can recover both liquid and vapor refrigerants.

Cons

● Not recommended for professional use

What Are the Different Types of Refrigerant Recovery Tanks

Types of refrigerant recovery tanks are:

- DOT-Approved Steel Tanks:

These refrigerant recovery tanks are made from steel and are designed to meet the safety requirements set by the Department of Transportation (DOT). They are commonly used in the commercial and industrial HVAC industry and are available in various sizes. Steel tanks are durable and long-lasting, but they can be heavy and difficult to move around.

- Aluminum Tanks:

Aluminum recovery refrigerant tanks are lightweight and easy to transport, making them ideal for smaller HVAC systems. They are also resistant to corrosion, making them suitable for use with certain types of refrigerants. However, they may not be suitable for high-pressure refrigerants.

- Composite Tanks:

Composite tanks are made from a combination of materials, such as fiberglass and plastic, and are lightweight and durable. They are suitable for use with most refrigerants and are resistant to corrosion. However, they may not be DOT-approved and may not be suitable for high-pressure refrigerants.

- Refillable Tanks:

Refillable tanks are designed for repeated use and can be refilled as needed. They are commonly used in the commercial and industrial HVAC industry and are available in various sizes. Refillable tanks are cost-effective in the long run but require regular maintenance to ensure their safety and durability.

- Disposable Tanks:

Disposable tanks are designed for one-time use and are commonly used in residential HVAC systems. They are lightweight and easy to transport but not refillable and must be disposed of after use.

What Should You Look for When Buying a Refrigerant Recovery Tank

When buying a refrigerant recovery tank, consider these:

1. Size and Capacity:

Choose a recovery refrigerant tank with the right capacity for your needs. A larger tank may be needed for commercial applications, while a smaller tank may be sufficient for home use.

2. Material and Durability:

Look for a tank made of high-quality materials that can withstand the rigors of use, such as stainless steel or heavy-duty aluminum. You’ll also want to ensure that the tank is corrosion-resistant and able to withstand high-pressure environments.

3. Valve Type:

Choose a tank with the right valve type for your needs. A Y-valve is a popular choice for its ability to handle both liquid and vapor, while a ball valve may be easier to use and require less maintenance.

4. Portability:

Consider the weight and size of the refrigerant recovery tank, especially if you’ll be transporting it frequently. A lightweight tank with a convenient carrying handle can make it easier to move around.

5. Safety Features:

Look for tanks with safety features like pressure relief valves and automatic shut-off switches that can help prevent accidents and ensure safe operation.

6. Compliance:

Ensure that the refrigerant recovery tank is compliant with industry standards and regulations; the DOT and EPA establish regulations. Here’s how you avoid fines and penalties for non-compliance.

FAQ About Refrigerant Recovery Tank

1- How to recover refrigerant with a recovery machine?

Here are the steps:

1. Attach the hoses.

2. Purge the hoses.

3. Open valves.

4. Start the recovery machine.

5. Monitor the recovery.

6. Stop the recovery.

7. Store the refrigerant.

2- How many pounds of refrigerant can a recovery tank hold?

The capacity of a refrigerant recovery tank can vary depending on the size and type of the tank. Generally, recovery tanks can hold anywhere from 30 to 100 pounds of refrigerant, but there are larger tanks available that can hold up to 1000 pounds or more. It’s important to choose a tank with the appropriate capacity for the specific job to ensure safe and efficient refrigerant recovery.

3- How does a recovery machine refrigerant work?

A recovery machine refrigerant works by compressing the refrigerant in the HVAC system and moving it into the recovery tank. The machine uses a compressor, a condenser, and a filter to remove moisture, oil, and other impurities from the refrigerant before it is stored in the recovery tank. The recovered refrigerant can then be recycled or properly disposed of according to industry standards.

Conclusion

Selecting the finest refrigerant recovery tank might be difficult, but with the appropriate knowledge, you can make an informed choice. It is important to remember that adequate refrigerant recovery is both a legal necessity and an environmental duty. Invest in a high-quality recovery tank to comply with rules and conserve the environment for a brighter future. With the correct refrigerant recovery tank, you can be certain that you contribute to a safer and cleaner environment.