Today’s digital world is very fast-paced. Therefore, reliable & efficient fiber optic connections are more important than ever. It doesn’t matter if you’re setting up a new network or maintaining an existing one. The quality of your tools really makes a big difference. That’s where our VEVOR Optical Fiber Fusion Splicer JW4108 comes in. This advanced tool is designed to make fiber optic splicing easier, faster & more accurate. It ensures excellent connectivity for all your projects.

Table of contents

6 Benefits of VEVOR Optical Fiber Fusion Splicer

Our Fiber Fusion Splicer JW4108 is the best tool in the market due to its amazing benefits. Here are six essential selling points that make this splicer a must-have for professionals like you:

1. High Precision Splicing

The JW4108 is made to provide highly accurate fiber alignment. It results in low splice loss. This precision is also important for maintaining the strength of fiber optic networks.

2. Fast Splicing Time

It has an average splicing time of just 8-10 seconds. So, this splicer helps you complete projects quickly without compromising on quality. The speed is essential for large-scale installations & urgent repairs.

3. User-Friendly Interface

The splicer tool also has a 5-inch high-resolution color LCD screen. This makes it easy to see through settings. You will easily monitor the splicing process. The amazing interface reduces the learning curve. That means beginners can also use this tool effectively.

4. Durable & Portable

It is built to withstand tough working conditions. The JW4108 is compact & lightweight. This makes it easy to transport to various job sites. Its powerful construction ensures long-term reliability & performance.

5. Automatic Operations

The splicer has automatic splicing & heating functions. So, the splicing process becomes super-easy. Also, the manual intervention is reduced to a great extent. This automation increases efficiency & consistency.

6. Versatile Compatibility

Our instrument supports a wide range of fiber types including single-mode & multi-mode. Hence, it is a versatile choice for different projects.

Recommended For Your Project

Steps to Use Our Optical Fiber Fusion Splicer

Step 1: Prepare

You should begin by stripping the fiber coating & cleaning the bare fibers. Do it with alcohol to remove any contaminants. Also, use the precision cleaver to cut the fiber at a perfect 90-degree angle. This step is important for achieving a low-loss splice.

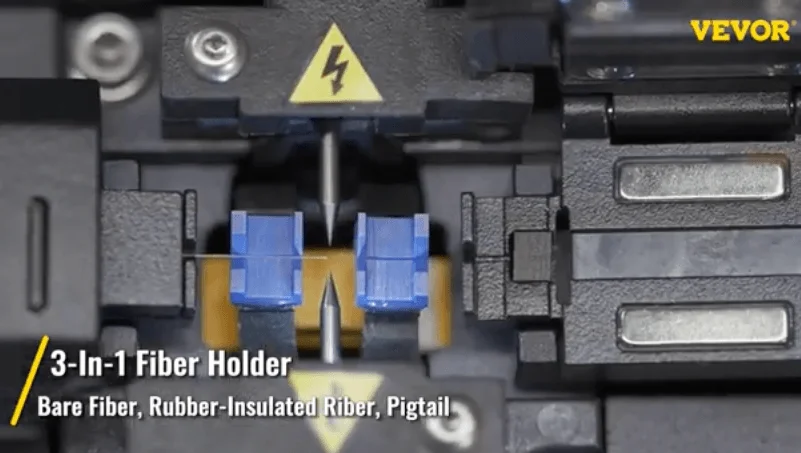

Step 2: Set Up the Splicer

Now, turn on the splicer & wait for it to initialize. The place the cleaved fiber ends into the splicer’s holders. Our device automatically aligns the fibers for best splicing.

Step 3: Splice

Then, initiate the splicing process by pressing the splicing button. The device will fuse the fiber ends together using an electric arc. Splicer has the ability to inspect the splice for quality. If the splice loss is within acceptable limits, the process will continue.

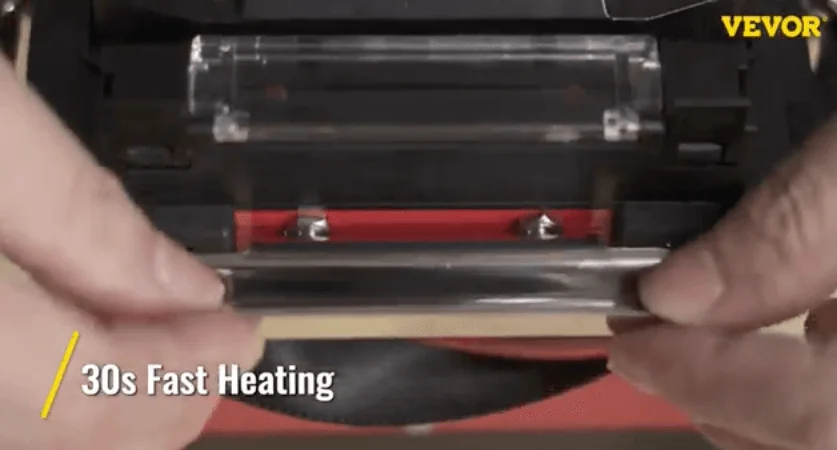

Step 4: Heat & Protect

Finally, transfer the spliced fiber to the heating oven. It will shrink the protective sleeve around the splice. After this, the splice is protected from environmental factors. You should also cool down the splice before handling it further.

Step 5: Final Inspection

At last, you can perform a final inspection, It makes sure the splice is secure & meets the necessary standards. Use a visual fault locator or an OTDR for a detailed analysis.

Frequently Asked Questions

Can the JW4108 splice different types of fibers?

Yes, of course. This JW4108 is compatible with:

- Single-mode fibers

- Multi-mode fibers

- & specialty fibers

How long does the battery last?

Our splicer tool has a high-capacity battery. It provides up to 200 splices per charge. So, you can handle extensive fieldwork without frequent recharging.

What is the typical splice loss with the JW4108?

The average splice loss is normally around 0.02 dB for single-mode fibers. Hence, minimal signal degradation is ensured.

Is training required to use the JW4108?

No doubt, our device is highly user-friendly. However, some basic training with fiber splicing can help you utilize the splicer more effectively.

What maintenance does the splicer require?

Regular maintenance includes:

- Clean the V-grooves & electrodes.

- Also clean fiber holders.

- Do some periodic calibration to maintain accuracy.

Conclusion

So, our Optical Fiber Fusion Splicer JW4108 is the best tool for you. You can easily work with fiber optics. It has high accuracy, fast operation & user-friendly features. These things make it ideal for both beginners & experienced professionals. You will finally ensure reliable fiber optic splicing for all your projects.Therefore, you should not wait any longer. Visit our VEVOR website today to learn more & make your purchase.