The VEVOR Propane Gas Forge is a strong and flexible tool made for people who love working with metal. It heats up quickly and stays hot, which is great for making knives, shaping metal, and other metal work tasks. Whether you’re a beginner or a professional, this forge can handle whatever you throw at it.

Why is this forge so great for your business? It’s built to last and gives you consistent heat every time you use it. This means you can rely on it for all your metalworking projects. You can use it for lots of different things. These include heating metal to make it easier to work with, or even crafting jewelry.

In this guide, we’ll discuss all the features that make this forge stand out. We’ll also give you a quick overview of how it works and what you can expect when you start using it. Let’s explore this amazing product further!

Table of contents

7 Best Features of VEVOR Propane Gas Forge

1. High-Temperature Capacity

This Gas Forge has a high-temperature capacity. It reaches up to 2450°F (1343°C). This feature makes it perfect for handling a lot of metalworking projects. If you want to shape, bend, or heat the metal, this tool will get the job done effectively.

2. Triple Burner Design

Our product boasts a triple burner design, which distributes heat more evenly throughout the forge. This ensures consistent and efficient heating of your workpiece.

With three burners, you can quickly achieve higher temperatures. It also provides better control over the heat, allowing you to customize the temperature.

3. Precise Temperature Control

With this gas forge, you get precise temperature control at your fingertips. It comes with a user-friendly regulator valve that lets you adjust the heat exactly the way you need it. No matter if it’s a delicate or heavy metal piece, you can easily adjust the temperature to suit your needs.

4. Forced Air System

This tool comes with a forced air system. This feature distributes the heat evenly throughout the forge that gives consistent temperature to your workpiece.

5. Durable Steel Construction

The propane gas forge is made of stainless steel. It ensures long-lasting durability. The strong construction can easily bear heavy use, providing reliability over the years to come. You can use it for long-term without any need of constant repairs and replacements.

6. Wide Applications

This equipment is suitable for a wide range of applications, like the following.

- Knife Making

- Blacksmithing

- Heat Forging

- Welding

- Annealing

- Tempering Metal

7. Easy to Use

This gas forge tool is designed in a user-friendly manner. It’s easy for both beginners and experts to operate. You can set it up easily without any complicated process.

Guide To Use Propane Gas Forge

Assembly

- Attaching the Burner Assembly: First of all, connect the burner assembly to the forge body. This ensures proper alignment and secure attachment.

- Installing the Gas Line: Attach the gas hose to the regulator and burner to ensure proper connections and leak-free operation.

- Positioning the Fire Bricks: Next, place the fire bricks inside the forge chamber. This creates the optimal heat distribution environment.

Ignition and Temperature Control

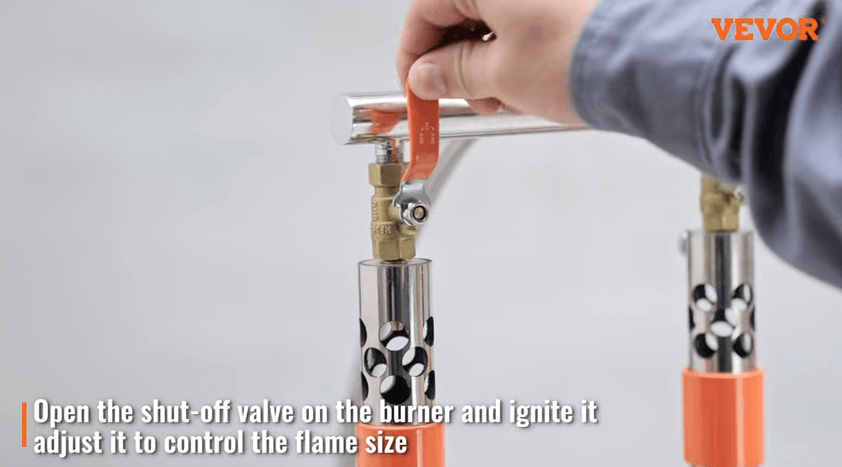

- Lighting the Forge: Now, safely light the forge using the igniter or a separate ignition source.

- Adjusting the Regulator Valve: Use the regulator valve to control the gas flow and achieve the desired temperature settings.

- Monitoring Temperature: Monitor the forge temperature using a pyrometer or other temperature measurement tools.

Metalworking Applications

- Knife Making: The video demonstrates the process of heating and shaping knife blades within the forge, showing the main techniques and considerations.

- Blacksmithing: It showcases the forging process for different blacksmithing projects, like heating, hammering, and shaping various metal elements.

- Heat Treating: The video also shows the heat-treating process for different metals, explaining the importance of controlled heating and cooling cycles.

Frequently Asked Questions

What safety precautions should I take when using the forge?

Always wear safety gear, including gloves, eye protection, and heat-resistant clothing. You have to ensure proper ventilation and never leave the forge unattended while in operation.

What type of propane gas is recommended?

You should use commercially available propane gas (LP gas) that meets industry standards.

How long does it take to reach the desired temperature?

The heating time varies depending on the initial temperature and desired setting. Normally, it takes around 10-15 minutes to reach maximum temperature.

What maintenance is required for the forge?

You should regularly clean the forge chamber and burner assembly to remove debris and ensure optimal performance. Inspect the gas lines and connections for leaks periodically.

Summary

So, the VEVOR Gas Forge is fantastic equipment for people who love working with metal. It’s super strong, heats up well, and lets you control the temperature exactly how you want it.

If you’ve been making things out of metal for a long time or just getting started, it is perfect for helping you make cool stuff. When you use the VEVOR Propane Gas Forge, you’ll feel like a pro in your projects. So, why wait? Get yours now and start making awesome metal creations!