Wire stripping machines used to efficiently remove the insulation or outer covering from the electric wires play an immense role in different industries, such as recycling, manufacturing plants, and electrical repair facilities. They ensure the efficient and safe handling of the wires, reducing the risks of injuries associated with manual wire stripping.

VEVOR wire stripping machine is a fully automated premium tough quality wire stripper with an incredibly low price and is delivered relatively quickly and securely with a 30-day free return option. The VEVOR wire stripping machine manual provides an in-depth guide about how to use this tool efficiently, as well as how to acquire the full potential from it. So, here’s the VEVOR wire stripping machine manual as the key to unlocking precision and efficiency.

Table of contents

An Overview of the VEVOR Wire Stripping Machine

Features and Specifications

The VEVOR wire stripping machine manual highlights the advanced features and specifications that contribute to its effective handling. The VEVOR wire stripping machine (21 x 14 x 10 inch / 53.34 x 35.56 x 25.4 cm dimension and 65.4 lbs / 29.68 kg weight) is made up of heavy-duty aluminum alloy, thus able to withstand tough environments.

It is equipped with a professional LCD panel and a microcomputer panel. It comes with a powerful 200W motor, which allows easy wire stripping at 60 ft/min 1400 RPM, cutting large numbers of wires (3000-8000 pcs per hour).

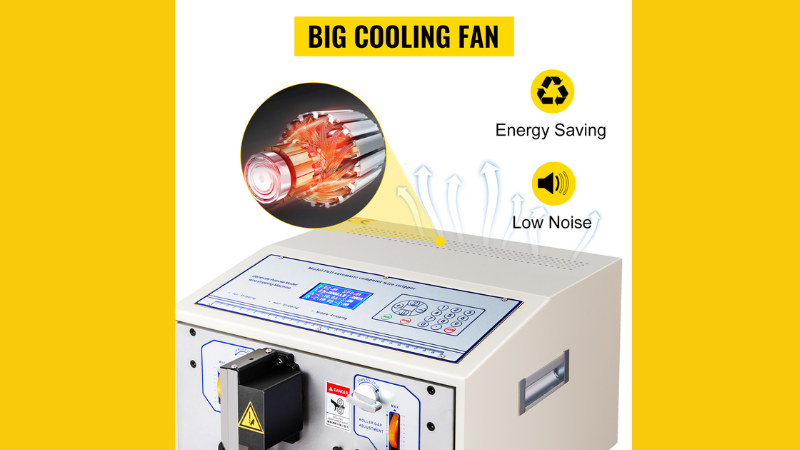

1-9999 mm of wires can be cut with this tool. Wire stripping can be hazardous even if operated with wire stripper tools. Thus the shell and screw nuts of the VEVOR wire strippers are designed with high stiffness and hardness, protecting the tool’s blades. The heat generated from the wire stripping is dissipated fast with a powerful big cooling fan to save energy and increase the tool’s performance.

Starting with the display, the LCD interface of model SWT508-SD is easy to understand in English. The machine requires a power supply of 110V and 60Hz, generating a 200 W power. Its English LCD interface displays a cutting length of 1-9999 mm with 0.2 ± 0.002 x L mm cutting tolerance and stripped length of Thread 0-35mm, Line End 0-15mm.

The VEVO wire stripper features 11 department stripping for intermediate cuts, accommodating wire core cross-sections of 0.1 to 4.5 mm ². This wire stripping tool with hard tungsten steel blades is suitable for PVC, Teflon, silicon, and glass fiber wires. It would help if you turned on the machine and manually set up the device for the particular wire to be stripped using the controls on the LCD.

Advantages of Using the VEVOR Wire Striping Machines

The usage of the VEVOR wire stripping machine proves to be cost-effective since it comes with incredibly low prices. From its VEVOR Manual Wire Stripping Machine to its VEVOR Wire Stripping Machine DA, VEVOR offers a wide price range.

Stripping 3000-8000 pieces of wires per hour reduced much of the time, and the LCD, with an easy-to-understand operation, helped prove this tool to be labor efficient.

Moreover, the tool works at great precision, i.e., the stripped length for threads and line ends are specified with the precision of thread 0-35 mm and line end 0-15 mm. The ability of this tool to amend cut errors enhances precision, making it a reliable and efficient wire stripper tool.

Applications and Industries The Use of The VEVOR Wire Stripping Machine

The VEVOR wire stripping machine applies to various industries due to its precision and efficiency features. VEVO wire stripping machines are required to manufacture electronic components, circuit boards, and wiring systems in the electronics and electric sectors.

They are also used to prepare wires for installations, ensuring reliable connections in building and infrastructure projects. One of the features of the VEVO wire stripper machine is that it can handle various sizes of wires and insulation types, making it important in the automotive industry and, thus, reliable wiring in vehicles.

In the recycling and waste management sectors, the VEVOR Wire Stripping Machine is an essential tool for recovering important and valuable metals from electrical and electronic devices that have been thrown away or discarded, such as helping to extract copper, aluminum, and other materials.

On the other hand, in the construction and manufacturing sector, the VEVO wire stripper can be helpful in the wire preparation processes, thus enhancing efficiency in the construction assembly lines.

How to Set up The VEVOR Wire Stripping Machine

Here are VEVOR wire stripping machine instructions for assembly, which you can follow for a smooth VEVOR wire stripper experience;

Assembly Instructions

- Power on and display the setup:

Connect the machine to a power supply (AC 110V 60Hz).

- Understand the control panel and functions:

The control panel comprises 23 keys and a 192×64 dot matrix LCD.

The functions for each of the keys are described in the manual

- Sett the parameters:

Set the parameters for stripping length, cutting Tolerance, stripped length, line core cross-section, maximum catheter diameter, stripping speed, drive mode, and cut error according to the wire to be stripped. For example;

Stripping Length: 0.04 – 393.7 inches / 1-9999 mm.

Cutting Tolerance: (0.2 ± 0.002 x L) mm.

Stripped Length: Thread 0-35 mm, Line End 0-15 mm.

Line Core Cross-Section: 0.1-4.5 mm² (AWG12 #-AWG32 #).

Max. Catheter Diameter: ¢ 7.

Stripping Speed: L = 100 mm/h, 3000-8000 pcs/h.

Drive Mode: Four-Wheel Drive.

Cut Error: Adjustable

- Adjust stripping settings:

Set the striping length, front half stripping, the total length of the wire, and rear half stripping values.

Adjust the knife value and retreat the value for precision.

Set the cutting, feeding, and stripping speed parameters and adjust the output settings for the total count.

Set parameters for twisting mode, wire twist speed, and twisting strength from the LCD.

- Setting up the program number and work mode switching:

Set the program number and enter the work mode settings on the display.

- Knife position adjustment:

Remember to ensure the knife position adjustment is correct for accurate cutting. Now, you can run the setup.

Safety Precautions

- Ensure the safe operation of the VEVO wire stripper machine by following the precautions and reading the VEVOR wire stripping machine instruction manual thoroughly and carefully.

- Familiarize yourself with the control control panel’s keys so the user can better stop the process when needed in an emergency.

- Moreover, adhering to the communication protocol for precise machine control is better.

- Adjusting the knife cutting positions is the most important thing and should be noted.

- However, the regular maintenance and proper training of the operating personnel is the most important factor contributing to a safer and more efficient working environment

VEVOR Wire Stripping Machine Manual: How to Operate It?

To operate the VEVOR wire stripping machine properly, look at the VEVOR wire stripping machine manual provided here;

- The system interface consists of a 192×64 dot matrix LCD and 23 keys where each key has a specific function.

- A short press on any key initiates a single-step action in standby mode. Hold the key for about 3 seconds to activate continuous operation.

- Press the ‘Start/Stop’ button to start or stop the machine’sthmachine’s operation.

- In the standby mode, the’ Reset Butt’n’ button resets the machine. During operation, it shuts down the machine and performs a reset action.

- There are various keys for setting up parameters related to wire stripping, twisting, speed, and more.

- Enter the stripping parameter setup state in standby mode by pressing the corresponding button.

- Adjust parameters such as front length, stripping length, total length, and knife values according to your requirements.

- Ensure the knife values are adjusted appropriately for the wire thickness to achieve the desired cutting depth.

- Press the corresponding button in standby mode to enter the speed parameter setup state.

- Adjust parameters such as cutting speed, feeding speed, stripping speed, and pause time to optimize machine performance.

- Enter the output settings by pressing the designated button in standby mode.

- Adjust parameters, such as ‘total output,” according to the production needs.

- Enter the twisting parameter setup state by pressing the corresponding button in standby mode.

- Adjust parameters such as twist wire mode, twisting strength, speed, etc.

- Enter the program number setup state in standby mode to set program arguments. Use the designated buttons to switch between different work modes.

- When it powers on, the screen displays the boot screen for about three seconds. After that, the machine starts running.

- RS485 communication is supported in the machine, which allows direct control via a host computer (e.g., PLC or PC) using specific commands.

VEVOR Wire Stripping Machine Troubleshooting

Ensure to comply with the instructions in the VEVOR wire stripping machine instruction manual. If you cannot solve the issue or the issue listed in the VEVOR wire stripping instruction manual, feel free to contact customer service. Here’s a list of some of the issues and their troubleshooting:

- Troubleshooting fast operations: The correlation between the knife value, cutting depth, wire thickness, and knife retreat values are provided in the manual instructions for the VEVOR wire stripping machine. The reference parameter data helps the users set up the machine for different wire sizes.

- Troubleshooting the key functions: Users can easily understand the different functions using the designated keys on the control panel as listed in the guide for different functions like single-step operation, machine start/stop, reset action, and various parameter setups.

- Troubleshooting through boot screen: when the machine is powered on, a boot screen is displayed on the main screen for a minimum of 3 sec. Users can use this setup to ensure proper startup.

- Troubleshooting the adjustment of knife cutting positions: Proper adjustments to the knife cutting positions are important for maintaining cutting depth consistency.

- For thread stripping without a tail, start the machine and adjust the machine MAX2 knife position to 8 to 10 mm nose distance and 34mm V shape bottom points. Then, align the left knife rack, adjust the gears, and ensure the proper blade distances are fine. After these adjustments, secure the knife rack gears and restart the machine. Then, fine-tune the knife value for any cutting depth changes.

- Troubleshooting wire skin barotrauma: For such issues, first examine the inlet wheel or pulley for the barotrauma. The wheel pressing force should be small. If it still needs to get set up, contact the company to purchase a new rubber tire.

- Troubleshooting the thread peel line core cut: Adjust the” “diameter” r” and retry until the core is undamaged.

- Troubleshooting length exceeds set length: Adjust wheel pressure, clean the pulley, and minimize wheel clearance.

- Troubleshooting if the length is less than the set length: Address wire thickness, clean the wheels, and ensure the smooth wire is conveying.

- Troubleshooting if the fan works and the machine does not move: Check if the fuse is burned due to voltage instability or illegal operations. In such cases, replace it if needed. If the problem persists, contact customer service.

- Troubleshooting the inclined incision tangent: In such cases, a straightening device for curved wire is used. Then, ensure proper lead alignment and inspect wire pipe positioning.

Conclusion

A VEVOR wire stripping machine is an essential tool across diverse industries that enhances the efficiency and safety of wire handling. Its features, such as the heavy-duty aluminum alloy construction, LCD interface, and powerful motor, contribute to its precision and effectiveness. The machine’s applications span electronics, construction, automotive, and recycling sectors, addressing various wire sizes and insulation types.

The VEVOR wire stripping machine’s cost-effectiveness, impressive speed, and precision make it a reliable choice for wire stripping tasks. The detailed VEVOR wire stripping machine manual provided here serves as a comprehensive guide, ensuring users unlock the tool’s full potential.

By following the assembly instructions described in the VEVOR wire stripping machine instruction manual, troubleshooting steps, and safety precautions, operators can maximize the performance and longevity of this automated wire stripping solution, contributing to a safer and more efficient working environment. So, invest in a VEVOR Wire Stripping Machine and start wire striping without hassle.