You might be surprised to know, but lathe machines are one of the most primitive tools known to humanity. Dating back to 1300 BC in Egypt, the first lathe was a simple machine requiring one person to turn the workpiece while the other shaped the workpiece using a sharp tool.

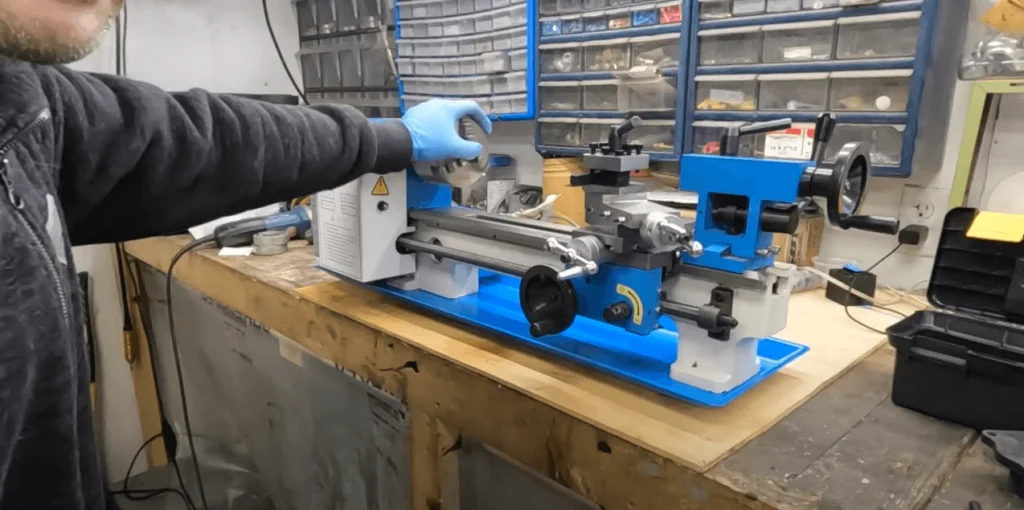

So, what is a lathe machine, and what does it look like today? From the crude beginning until today, this equipment has gone through two centuries of modernization.

If you are interested in learning more about lathes, you have come to the right place. In this section, we’ll delve into details of different types of lathe machines, their parts, and more.

Table of contents

Defining a Lathe Machine: Beyond the Basics

Basically, these machines shape wooden or metallic products by removing undesired material from a rotating workpiece in the form of chips. It works by rotating the workpiece about an axis while a stationary cutting tool removes unwanted material until it takes your preferred shape.

Other than this, what is a lathe machine used for?

Although removing material from a workpiece is the primary function, its versatility has earned the lathe the tag of the “Mother of All Machine Tools.” These machines are great for many product fabricating operations like sanding, drilling, cutting, deformation, turning, etc. You will also see them in metalworking, thermal spraying, glass processing, and wood tuning processes.

Being as versatile as they are, lathes significantly contribute to the craftsmanship in various industries. They enable craftsmen to produce artistic designs and their prototypes with maximum precision. Not only this, they can easily customize, repair, and produce a wide range of products in masses.

Parts of a Lathe: Decoding the Machinery

For a thorough understanding of the detailed working mechanism of lathe machines, it is essential to know what parts constitute them.

A Bed

A bed made of cast iron and cast nickel alloy supported on broad box-section columns holds all the machine parts together. This solid component, acting as a foundation of your assembly, makes turning the workpiece easier. It is a flat surface featuring rails that securely hold the headstock, tailstock, and carriage in place.

The Headstock

Found on the end of the bed, a headstock’s main function is to transmit power to the different parts of a lathe machine. Also, it houses a necessary transmission mechanism with speed-changing levers to adjust the speed.

Part of its role is to support the spindle in the bearing and align it accurately. The bearing helps a lathe to rotate the workpiece against the tool bit.

The Tailstock

Next on our list of a lathe machine’s parts is a tailstock, which is a movable casting rod opposite the headstock. It is the loose head of the machine, so its body is mounted on the base in a way that allows it to move to and fro freely.

Its main function is to hold the workpiece while being machined and support the tool bit for performing operations like drilling, reaming, and tapping.

Carriage

A carriage sits between the headstock and tailstock with the primary function of manipulating, supporting, and guiding the tool bit during operation. It has the following five parts:

● Saddle: A saddle is a casting featuring an H shape mounted on the top of the lathe machine. It provides support to cross-slide, compound rest, and tool post and enables the cross-slide to move back and forth.

● Cross-slide: Another part of a lathe that you’ll find on the top is its cross-slide. Its main function is to allow the tool bit to move to and fro. That’s why the upper surface of a cross-slide has T-slots to aid the fixing of a rear tool post or coolant attachment.

● Compound Rest: A compound rest, situated on the top of a cross-slide, supports the tool post and cutting tool in various positions. It plays a key role in tasks that require angled cuts, taper turning, and other operations where precise tool positioning is essential for achieving the desired machining outcome.

● Tool Post: A tool post mounted on the compound rest holds various cutting tool holders. The holders rest on a wedge that permits easy adjustments of the height of the cutting edge. Fixed on the top slide, it gets its movement from the saddle, cross slide, and top slide.

● The Apron: The apron mounts on the saddle and hangs over the front of the bed. It plays a crucial role in providing control and functionality to the carriage of the lathe machine.

Motor and Spindle Attachments

You’ll find the motor under the lathe bed on the left side near the headstock. Usually, it is a hydraulic or an electric motor.

The spindles, including the main spindle, hold the workpiece and need various attachments. The attachments include centers, chucks, and faceplates to position and secure the workpiece. The main spindle is hollow and threaded on the outside for the sake of these fittings.

The Inner Workings: How Does a Lathe Machine Operate?

Now, let’s have a look at how these components of a lathe machine work together and on what principles:

Mechanical Overview

The rotation of the workpiece and its controlled movement along its axis involves the principle of turning; the cross-slide moves the cutting tool across the end of the workpiece, employing the principle of facing.

Cutting external or internal threads on a workpiece by engaging the lead screw of the lathe involves the principle of threading. However, to cut the same workpiece into a conical shape, the compound rest has to be set at an angle to the lathe axis, employing the mechanism of taper turning.

Understanding the Turning Process

● Step 1: The chunk holds the workpiece securely between a headstock and a tailstock where it has to revolve.

● Step 2: The spindle connected to a motor helps rotate the workpiece at its axis.

● Step 3: A cutting tool, distinct for the type of shape you require, is fixed in the tool holder at an appropriate distance from the workpiece.

● Step 4: The blades of the cutting tool chip off the undesired material from the rotating object until it reaches your preferred shape.

Exploring the Different Types of Lathe Machines

In this section, let’s have a look at some widely used types of lathe machines and their applications.

A Journey into Engine Lathes: Powering Precision

Engine lathes are one of the most commonly used machines in metalworking. These machines have mechanisms for controlling the rate at which the cutting tool advances along the workpiece. This feature helps them achieve accurate and consistent results.

Their features make them suitable for both small and large-scale industrial applications, such as automotive, aerospace, and manufacturing.

Construction Lathe: Building Foundations

These machines include both metalworking and woodworking lathes that help the machinists meet specific design and structural requirements.

● Metalworking Lathes: These lathes are essential for fabricating and assembling metal structures used in construction.

● Woodworking Lathes: They can create several cylindrical and symmetrical shapes, such as table legs, balusters, and other decorative or functional wooden elements.

The Artistry of Metal Lathes: Shaping Your Vision

The artistry of metal lathes lies in their ability to transform raw metal into functional and precisely crafted objects. Skilled machinists experiment with shapes, contours, surface finishes, curves, engravings, and patterns to create unique and aesthetically pleasing metal pieces.

They enable a perfect amalgam of creativity and technical skills to transform basic metal into something intricate and decorative.

How to Use a Metal Lathe: A Practical Guide

Before you learn how to operate a metal lathe, here are some terms that you need to remember:

● Power, expressed in Watts or HP, expresses the engine’s ability to carry out a task.

● Rotation Speed, expressed in RPM, expresses a lathe’s motor speed.

● Swing Over Bed that indicates the maximum diameter of the workpiece that you can use.

● Center Distance denotes the longest piece of work the headstock and tailstock can hold between them.

Primary Steps

Using the VEVOR metal lathe involves a series of following steps:

- The machine allows you to set up the cutting tool according to your project. So, make adjustments to your lathe to suit your requirements.

- Mount the object on the headstock, put the chuck guard on, and select the direction of rotation (forward or reverse).

- Set a certain RPM, move your tool post near the rotating object, and try to give a light pass.

- After completing passes with the tools, you will see the workpiece taking your preferred shape.

Safety Precautions: VEVOR is concerned about its user’s safety, so it has included several security features in case of emergency, such as an emergency stop switch, overload protection, a chuck cover power off switch, and a control panel security switch.

Summing Up

Lathe machines have stood as indispensable tools for machining and metalworking, embodying versatility, precision, and adaptability. Constituently, a bed, headstock, tailstock, spindles, tool rest, and motor are the main parts of a lathe.

If you are looking for an all-in-one machine capable of turning, facing, threading, and tapering, check out VEVOR’s range of products. We have amazing products in various sizes and affordable price ranges. You can explore your options and make an informed choice based on your preferences.