If you’ve ever tackled a tough mechanical job, you know that not all tools are created equal. This is where an impact socket comes to the rescue, making your job much easier.

Unlike regular sockets, impact sockets are built to withstand the intense force delivered by impact wrenches. These tools are designed to handle high-torque applications without sweat. They feature thicker walls for added strength and usually have a black-oxide coating that enhances their durability while resisting rust and corrosion.

In this blog post, we’ll explore impact sockets, how they differ from standard sockets, and why they’re essential for tackling tough fastening jobs.

Table of contents

What Makes Impact Sockets Special?

In simple terms, impact sockets are designed for use with impact wrenches or drivers. These power tools deliver high torque to fasteners, which means they need a socket that can withstand the hammering action without breaking. That’s where impact sockets come in.

Why the Material Matters

The durability of impact sockets comes down to the materials they’re made from. Most of these tools are crafted from high-strength alloys like chrome molybdenum (Cr-Mo) or chrome vanadium (Cr-V). Cr-Mo is a popular choice because it’s so tough. These materials are chosen carefully to withstand constant stress without deforming or breaking. For instance, many impact sockets, such as those from VEVOR, have a black oxide finish. This finish not only helps to resist corrosion but also gives a non-slip surface, making them more accessible and safer to handle.

Key Features of Impact Sockets

Durability: Impact sockets are made from high-strength materials and are built to last. They can withstand the intense torque from impact wrenches.

Safety: They reduce the risk of breaking or shattering during use, which is a big deal when dealing with heavy machinery.

Efficiency: Designed to transfer torque more effectively, they get the job done quicker, saving time and effort.

Why Should You Use Impact Sockets?

Enhanced Durability

With their robust construction, impact sockets absorb and distribute the force delivered by impact wrenches. This makes them essential for tasks involving frequent or high-intensity fastening and loosening, ensuring the tool’s longevity and reliability.

Safety Considerations

Using impact sockets significantly lowers the risk of tool breakage and potential injury. The thicker walls and high-quality materials mean the socket is less likely to shatter under pressure, a common issue with standard sockets when used with impact tools. This enhanced safety is vital, especially in professional settings where tool integrity directly impacts user safety.

Performance Efficiency

Impact sockets provide a secure fit and reliable performance under high torque, improving the task’s efficiency.

Furthermore, the design ensures that the full force of the impact wrench is applied to the fastener, which minimizes the risk of slippage. This precision speeds up tasks and enhances work accuracy, leading to better overall outcomes and reduced wear on both the tool and the fasteners.

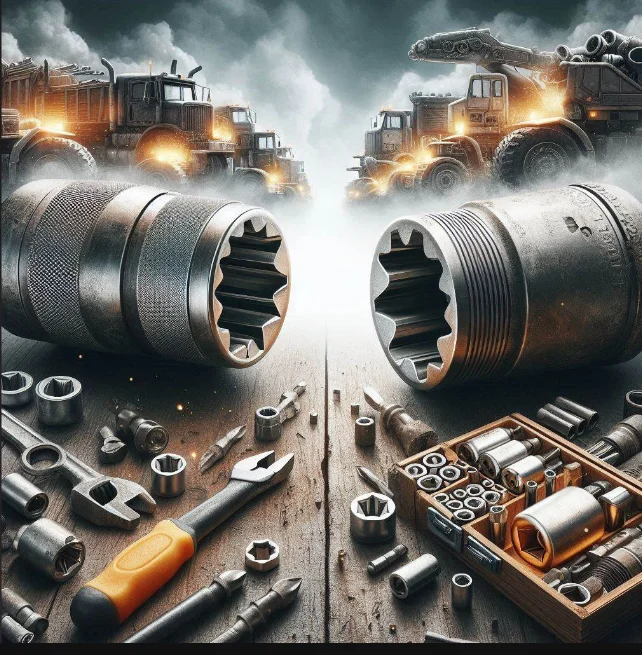

Impact Socket vs. Regular Socket: A Practical Guide

Structural Differences

Wall Thickness

Impact Socket: Designed with thicker walls to withstand high-torque forces.

Regular Socket: Features thinner walls suitable for moderate torque applications.

Material

Impact Socket: Made from tougher alloys such as chrome molybdenum (Cr-Mo), which can endure rigorous use.

Regular Socket: Typically crafted from chrome vanadium (Cr-V), ideal for general, lighter tasks.

Finish

Impact Socket: Comes with a black oxide finish that offers corrosion resistance and a non-slip surface, which is particularly useful in greasy or oily conditions.

Regular Socket: Often has a polished chrome finish, providing a sleek appearance and some rust resistance, but can be slippery when handling.

Performance Differences

High-torque, Repetitive Impact

Impact Socket: Excels in maintaining shape and providing a secure grip, significantly reducing slippage and rounding of fasteners.

Regular Socket: Can struggle under intense forces, with a higher risk of cracking or damage when used in high-torque situations.

Typical Use

Impact Socket: Best suited for heavy-duty tasks such as automotive repairs, industrial maintenance, and construction work, where repetitive impact and high torque are common.

Regular Socket: Ideal for manual torque applications and lighter tasks around the house or in less demanding professional settings.

Cost vs. Value

Initial Cost

Impact Socket: Generally more expensive due to its robust build and specialized materials.

Regular Socket: More budget-friendly, making it accessible for casual users and light-duty tasks.

Here is a summarized table to make you understand all this:

| Feature/Aspect | Impact Socket | Regular Socket |

| Wall Thickness | Thicker walls for high-torque forces | Thinner walls for moderate torque |

| Material | Tougher alloys like chrome molybdenum (Cr-Mo) | Chrome vanadium (Cr-V) |

| Finish | Black oxide finish for corrosion resistance and non-slip surface | Polished chrome finish for slick appearance and some rust resistance |

| High-torque, repetitive impact | Maintains shape and secure grip, reduces slippage and rounding | Struggles with intense forces, risk of cracking |

| Typical Use | Heavy-duty tasks like automotive repairs, industrial maintenance, and construction | Manual torque applications, light-duty tasks |

| Initial Cost | Higher due to robust build and specialized materials | Lower, budget-friendly |

| Durability | Exceptional, especially in professional settings | Adequate for light-duty and occasional use |

| Long-term Savings | More durable, safer, and efficient for high-torque applications | May cost more over time if frequently damaged or misused |

What Are Impact Sockets Used For?

You might be wondering where these tough tools are put to good use. They shine brightest in the automotive, construction, and manufacturing industries. Let’s break it down:

Automotive Industry

Picture a busy auto repair shop. Mechanics are constantly working on cars, trucks, and everything in between. They rely on impact sockets to deal with stubborn nuts and bolts that refuse to budge. Changing tires, working on suspension systems, or dismantling engines—impact sockets make these jobs faster and safer.

Construction Industry

Think about the energy and activity on a construction site. The tasks are vigorous, and the tools need to keep up. The demands are high, and the tools need to keep up. Impact sockets are a go-to for workers using impact wrenches to assemble steel structures, scaffolding, and heavy machinery. The best part? Their durability. They can handle immense pressure without cracking, helping construction workers do the job efficiently and effectively.

Manufacturing Industry

Machinery maintenance is crucial in manufacturing plants. Impact sockets help technicians secure or loosen large bolts on industrial machines, ensuring everything runs smoothly. These tools are indispensable, whether in assembly lines or heavy equipment maintenance.

How to Choose the Right Impact Socket

Selecting the right impact socket is crucial for both your work efficiency and safety. Here’s a straightforward guide to help you make the best choice:

Material Matters

Go for Quality: Always choose impact sockets made from chrome molybdenum (Cr-Mo) alloy. This material is known for its strength and durability.

Avoid Inferior Materials: Cheaper materials might not hold up under heavy use and could be unsafe.

Size and Compatibility

Measure Your Fasteners: Know the exact sizes of the fasteners you commonly work with. Choose sockets that fit these sizes.

Check Drive Size: Make sure the sockets match your impact wrench or driver. Common drive sizes include 1/4 inch, 3/8 inch, and 1/2 inch.

Why Compatibility Matters: A proper fit ensures effective power transfer from your tool to the fastener.

Brand and Quality

Invest in Reputable Brands: Well-known brands usually follow better manufacturing standards. Look for products with warranties or satisfaction guarantees.

Read Reviews: Check customer reviews and industry ratings to make an informed decision. Prioritize brands known for reliability and durability.

Why Quality Counts: High-quality impact sockets are built to last and perform well, making your work more efficient and safe.

By keeping these tips in mind, you can ensure your tools meet and exceed your expectations. Choose wisely to make your work both efficient and effective!

Tips for Using and Maintaining Impact Sockets: A Practical Guide

Proper Usage Techniques

The way you use impact sockets determines their effectiveness and life span. Here’s how you can make the most out of them:

Match the Size

Always match the socket size to the fastener to avoid rounding or stripping.

Fully Seat the Socket

Always check if the socket is fully seated on the fastener before applying torque.

Use with Impact Tools Only

Manual tools can cause unnecessary wear and damage to your impact socket, so always pair it with impact wrenches or drivers only.

Avoid Excessive Force

applying extra force can damage your socket, so try to stick to the provided torque limit.

Maintenance Tips

Maintaining your socket means extending its life to 10 times. Here’s what you need to do:

Regular Cleaning

Clean your sockets regularly to remove all kinds of dirt, grease, and debris.

Thorough Drying and Oiling

oiling prevents rust. So after drying, apply a coating of oil.

Organized Storage

Store your sockets in a dry, organized place like a toolbox or socket rack to keep them protected and easily accessible.

Periodic Inspections

Periodically inspect your sockets for signs of wear, cracks, or other damage. Replace any compromised sockets to maintain safety and performance.

Safety Precautions

Keeping safety in mind while using impact sockets is crucial. Follow these tips:

Wear PPE

Wear appropriate equipment for personal protection, such as safety glasses and gloves, to protect against flying debris and accidental slips.

Well-Lit Workspace

Always work in a well-lit area free from obstructions.

Why Choose the VEVOR Impact Socket Set?

High-Quality Alloy Steel

Durability is non-negotiable when it comes to tools. The VEVOR Impact Socket Set is made from high-quality alloy steel, ensuring it stands up to heavy use without wearing down. This sturdy construction means these sockets won’t easily crack under high pressure, providing you with the strength and longevity needed for any tough job.

Superior Performance

Whether using an impact wrench or turning them by hand, these premium chrome vanadium sockets deliver outstanding performance. Thanks to their 6-point, high-torque design, they connect with and grip the stronger flat sides of nuts and bolts. This design helps prevent rounding off the weaker corners, letting you work efficiently and effectively every time.

29 Sockets to Cover All Your Needs

No more fumbling around for the right size! Our 3/4-inch drive impact socket set includes 29 sockets, ranging from 3/4″ to 2-1/2″. With this set, you’ll always have the right socket for any task, big or small.

Easy to Organize and Carry

Keeping your tools organized can be a hassle, but it doesn’t have to be. The VEVOR 3/4-inch impact socket set has a durable storage case, so your sockets stay neatly organized. Plus, it’s portable! Whether you’re a seasoned mechanic or enjoy DIY projects on the weekends, you can take this case anywhere and always have your tools ready when needed.

Wide Application

This versatile set isn’t just for any odd job; it’s perfect for removing and installing wheel lug nuts and is particularly suited for most trucks, RVs, and other heavy-duty vehicles. Whether tackling routine maintenance or a big repair job, this torque multiplier truck set will be your trusty companion.

Final Words

If you work in automotive, construction, or manufacturing, you know how crucial it is to have the right tools for demanding tasks. Impact sockets provide the strength and durability you need, minimizing the risk of slippage and breakage. This makes them safer than regular sockets, which can crack under pressure. Investing in high-quality impact sockets, like those from VEVOR, ensures that your work is efficient and secure.

Choose VEVOR for your impact socket needs and experience the difference in quality and performance.