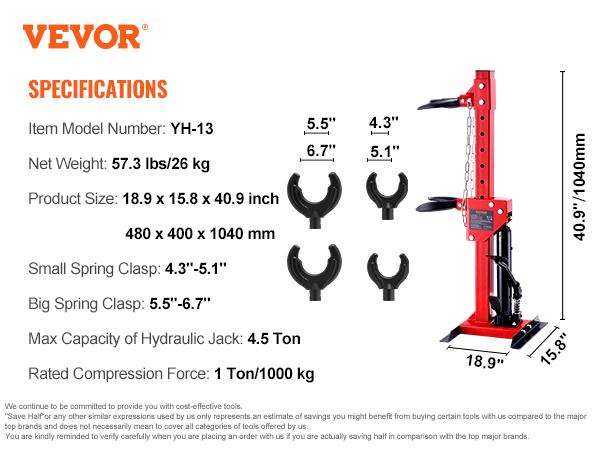

First off it uses the cheapest hardware (4.8), the adjustable pieces should use pins.. They have pins on the rest!.. SMH. The threads stripped out of the foot pedal with very little torque.. Again, cheap thin tubing that’s threaded. Lastly, when you have a shock in it, it tries to tip over! Why wouldn’t the legs extend out towards the work area? I don’t want to bolt it to my floor, so now I have to make a better pedestal, get pins and weld a nut in the tube. Oh, and the ID of the spring “cups” are too thick. They hit the body of the shock so makes it difficult for a coil over.