The VEVOR horizontal pneumatic liquid paste filling machine is ideal for fast and efficient filling. It can handle various liquids and pastes with ease. From 100 to 1000 ml, it’s suitable for different needs. This machine works well for small businesses looking to speed up their fill process. The pneumatic design ensures consistent and accurate fill every time. Therefore, it is ideal for products that need precise measurements. With a rapid rate of 5–30 bottles per minute, you can increase productivity. You should choose this machine if you need to fill a large number of bottles quickly and accurately. Can a person use this equipment for many different products? Yes!

This filling machine requires fewer refills. It reduces downtime and increases overall efficiency. With a large hopper, the machine can handle more products at once. This is especially useful for businesses with high production needs. The precise filler ensures that each container gets exactly the amount needed. It helps maintain product consistency. Product consistency is important because of the machine's design. It can be easily loaded and unloaded. So this makes the machine user-friendly and efficient. Because of these features, you can streamline your filler process in any business looking to streamline its filling process.

The stainless steel construction also makes cleaning easy. This is important for maintaining hygiene standards in food production. The machine's strong build ensures that it can handle various types of liquids and pastes without issue. Hence, it’s a versatile tool for different types of products!

The machine's filling speed ranges from 5 to 30 bottles per minute. This helps boost productivity and reduce labor costs. You can adjust the speed based on the viscosity of your product and the desired filler volume. This feature makes it suitable for different production needs. High speed ensures that businesses meet their production targets efficiently. This is especially beneficial for businesses that need to fill large volumes of product quickly. Due to its ability to handle a wide variety of products, the machine is a versatile tool for various industries.

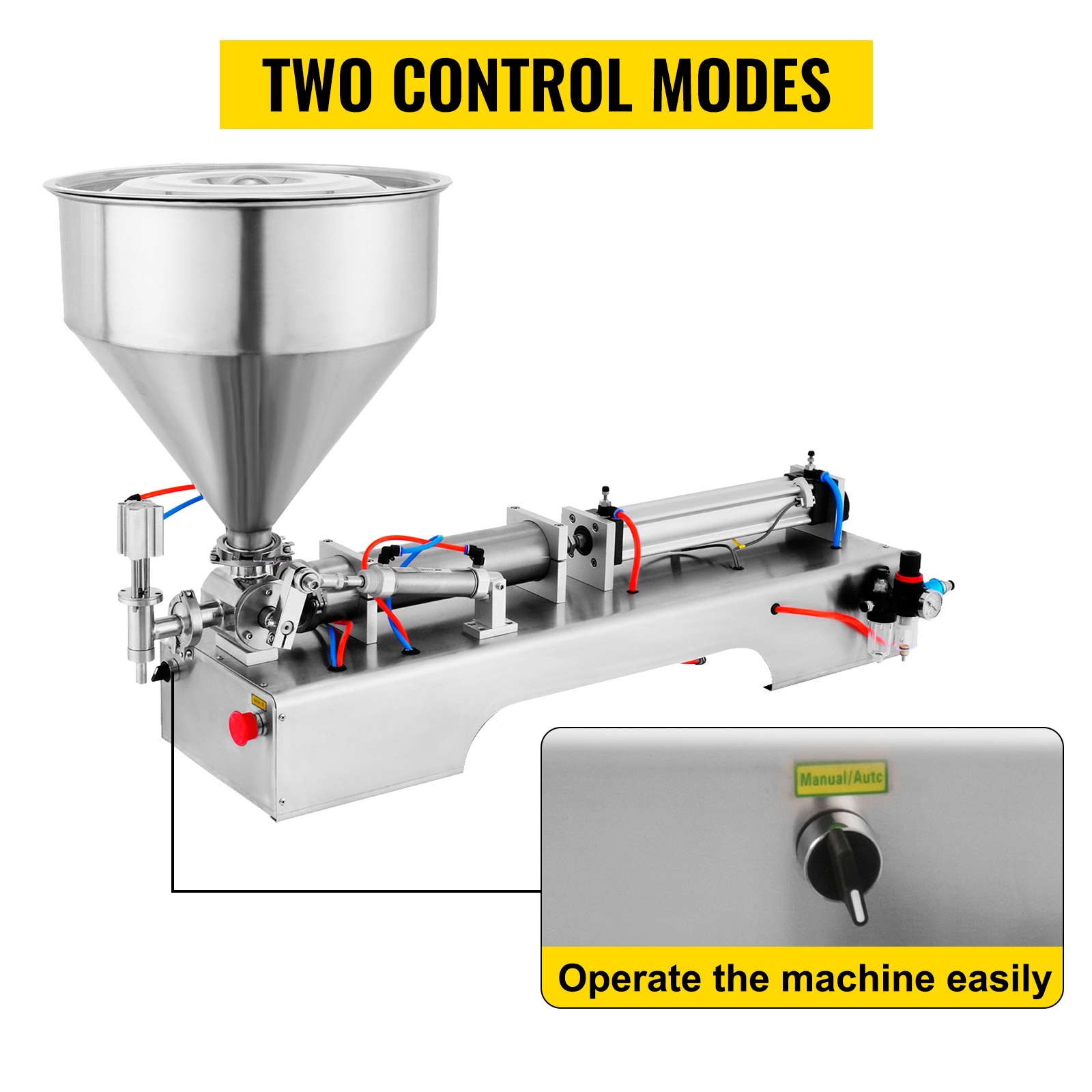

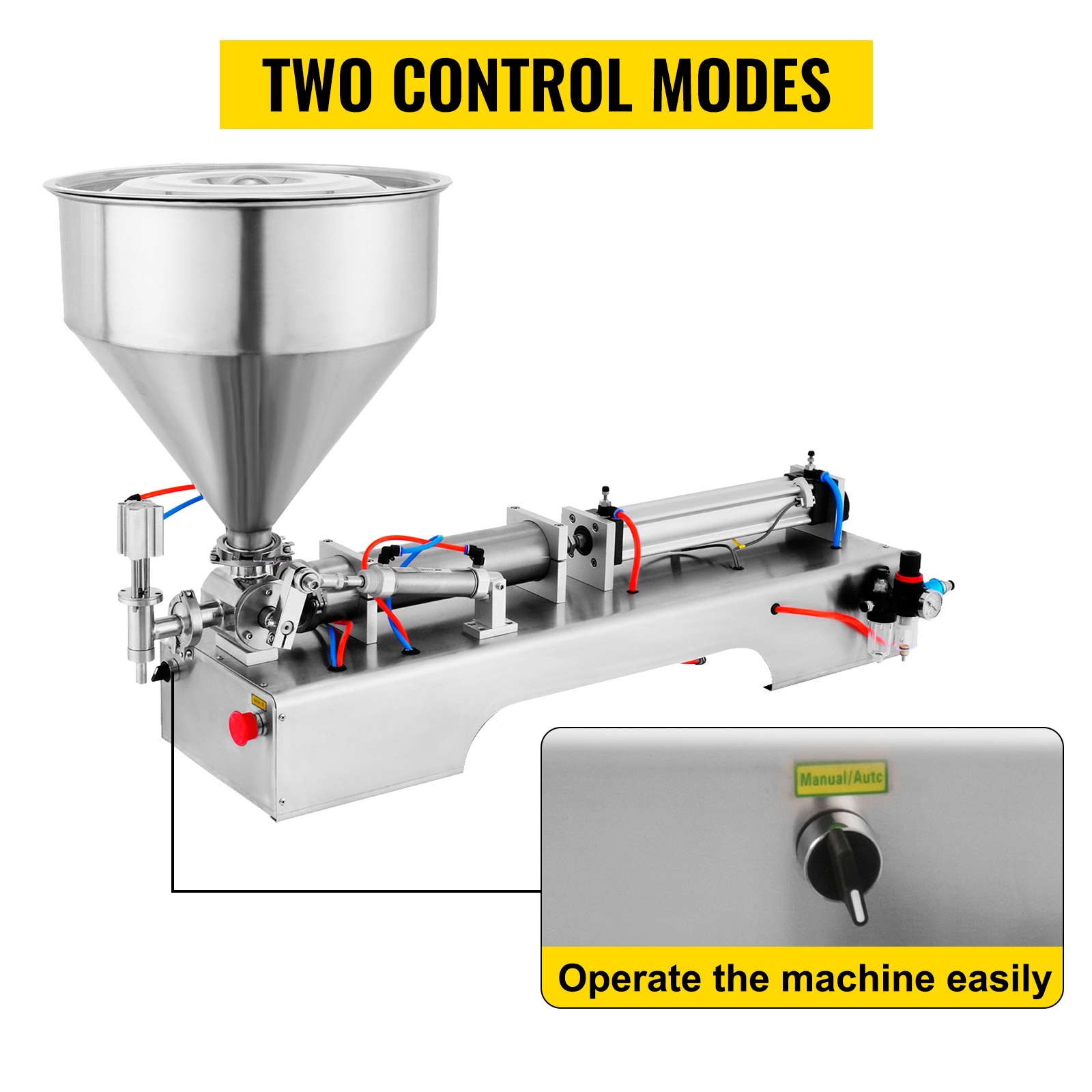

The design prioritizes ease of cleaning and operation. The stainless steel construction makes it easy to wipe down and maintain. This ensures that the machine remains clean and ready for use. The user-friendly design means minimal training is required to operate it. Therefore, it’s ideal for small businesses with limited staff. Additionally, its ease of use mitigates the risk of errors during operation. In this way, you can maintain product quality and consistency. Your machine's simple design allows for quick setup and ready use.

This filling machine is reliable and fast. It can be used for a variety of liquid and paste products. From thin liquids to thick pastes, it can handle various viscosities. Products such as thin liquids and thick pastes can be filled with ease. Reliability ensures that it can handle continuous use without issues. This is important for businesses that need to maintain dependable production flow. Fast filler speed helps to meet production targets efficiently. This makes it an excellent option for companies seeking a flexible filling solution.

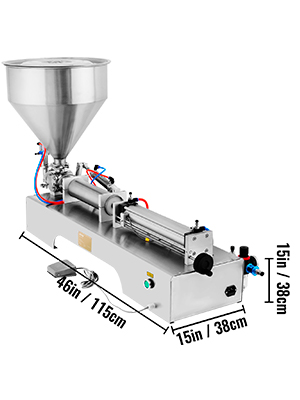

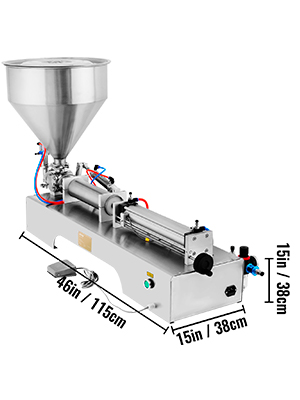

This machine has a compact design. It is ideal for small production lines with limited space. The compact style ensures that the machine fits well in various production setups. This is especially beneficial for small businesses that need to optimize their space efficiently. Due to its high functionality, it can perform well despite its compact size. This guarantees that businesses can achieve high production rates without compromising on space either. However, the device's design makes it easy to integrate into existing production line designs.

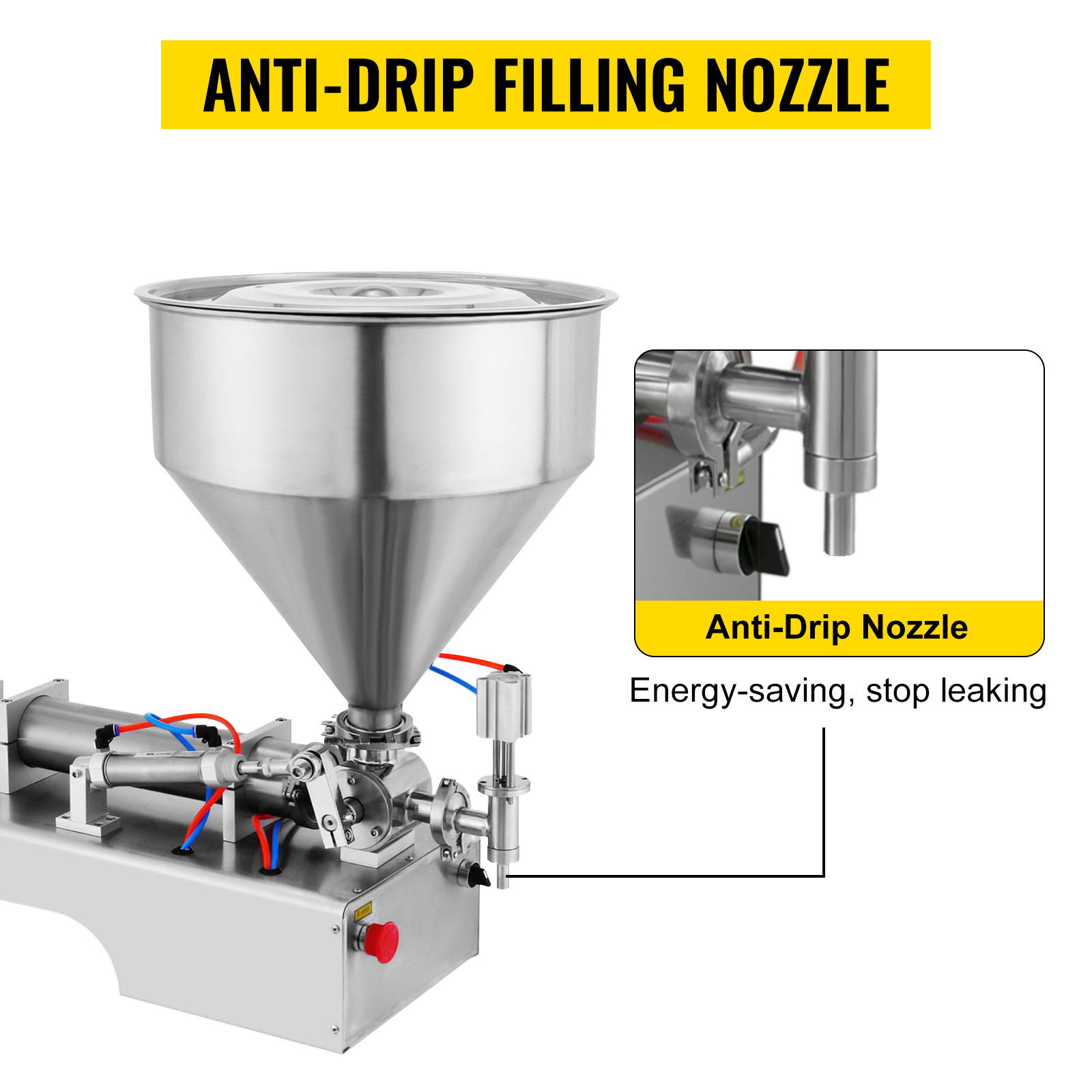

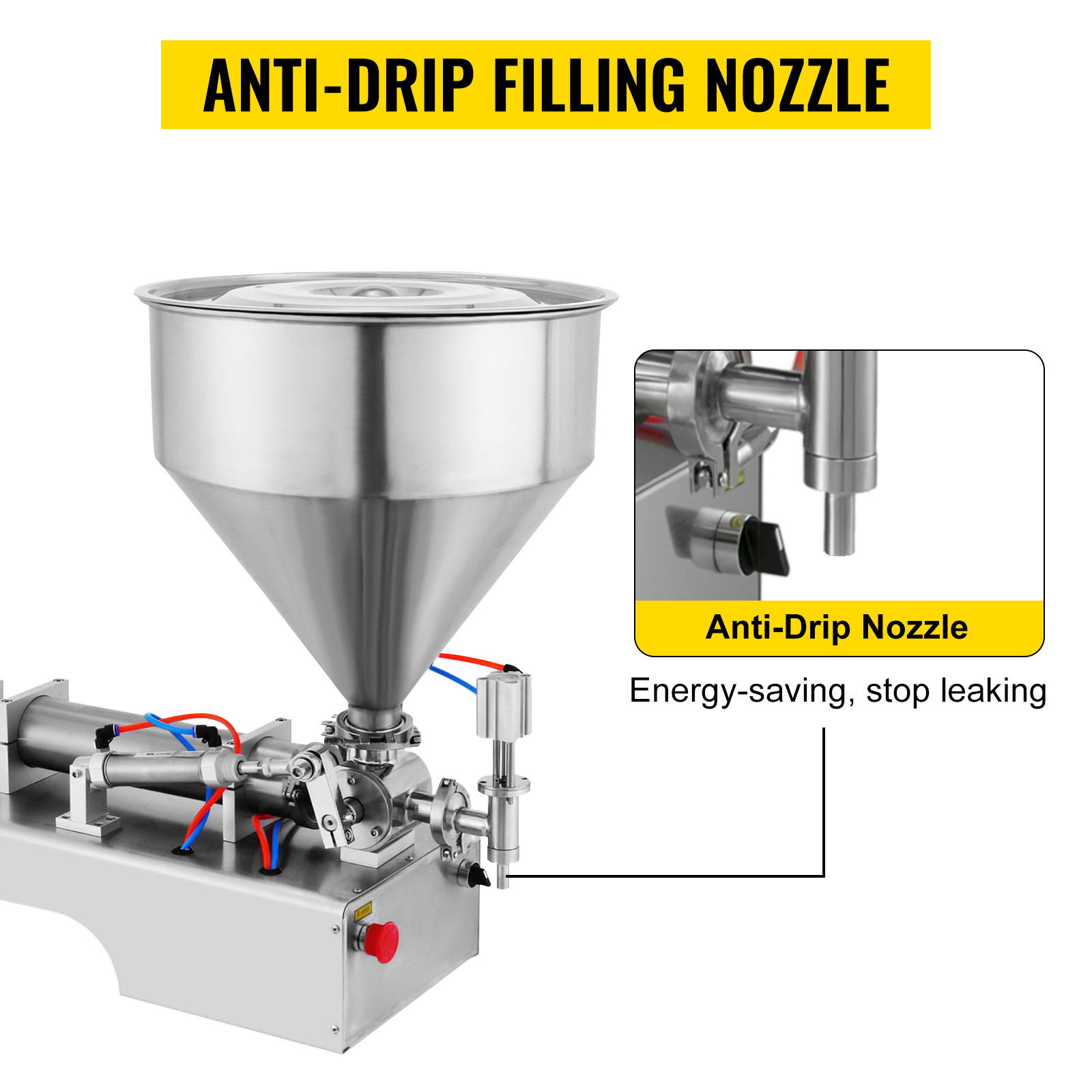

The machine features a no-drip nozzle. This ensures clean and precise filling. It helps maintain hygiene standards and reduce product waste. A no-drip design ensures that there is no mess during the filling process. This makes the machine simple to clean. Precision filling ensures that every container gets the exact amount needed. These steps help maintain product consistency and quality. The no-drop hose is especially useful for products that are difficult to clean up. Therefore, this makes the machine an incredibly valuable asset for businesses that need to maintain high hygiene guidelines.