Double Head

50 - 500 ml

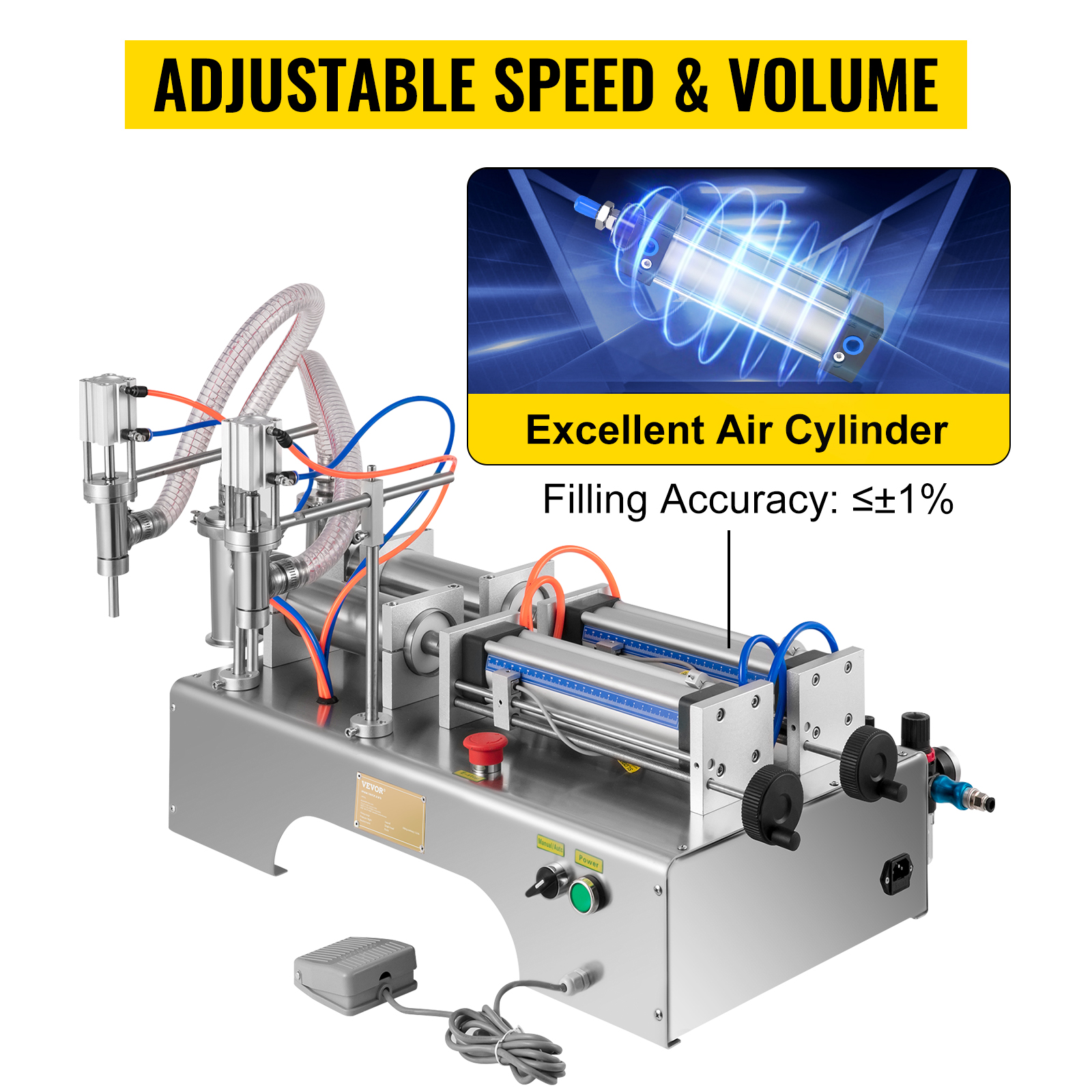

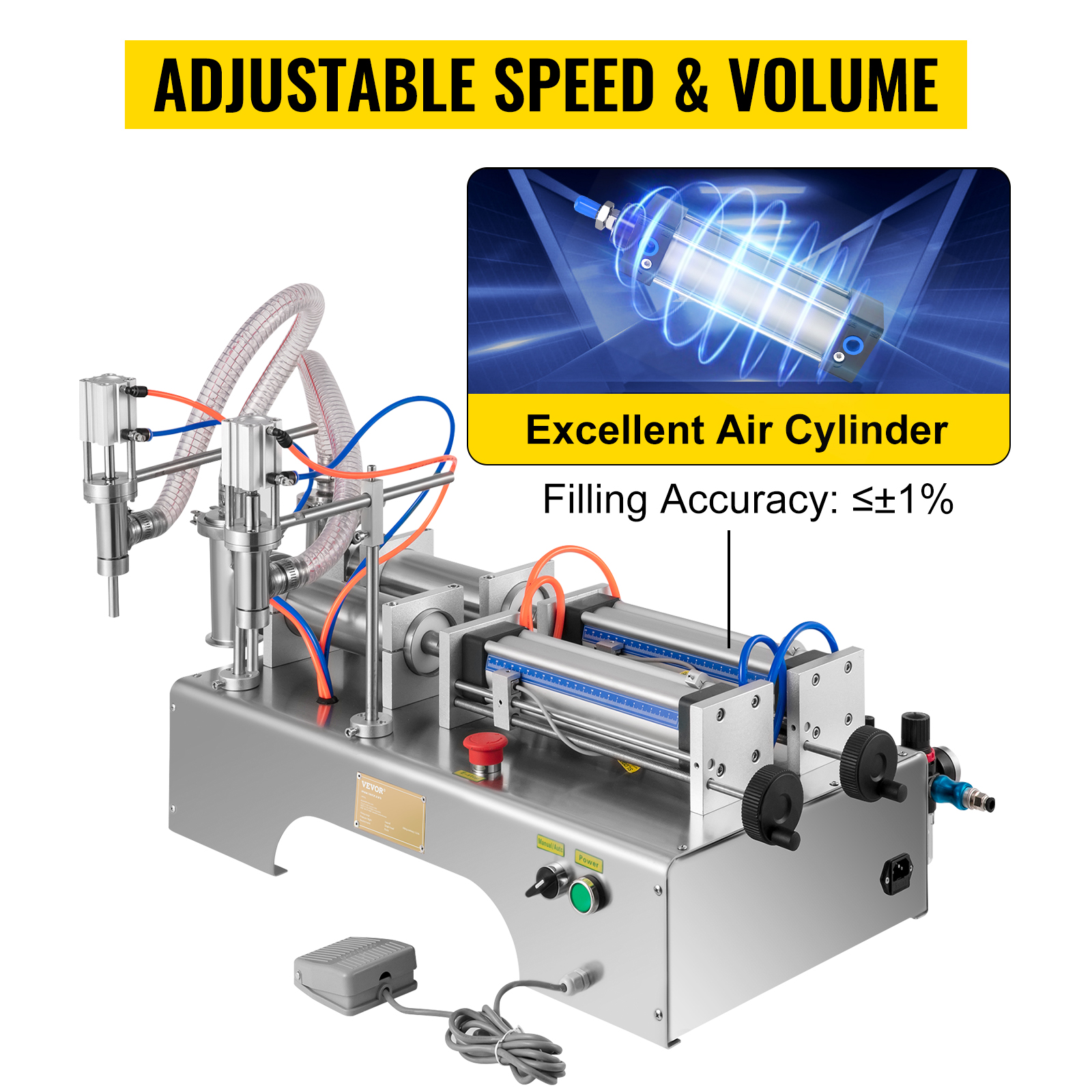

The VEVOR pneumatic liquid filling machine delivers high accuracy. It uses an advanced air cylinder. This ensures a filling precision of 1%. This is ideal for various filling needs. You can adjust the speed and volume as needed. The machine can fill 50-500 ml volumes. With 60 bottles per minute, it can fulfill up to 60 bottles per minute. That's why it’s suitable for both small and large operations. Its precision guarantees minimal waste, saving you money and resources. The excellence is consistent across different liquids. Therefore, this versatility is beneficial for multiple industries.

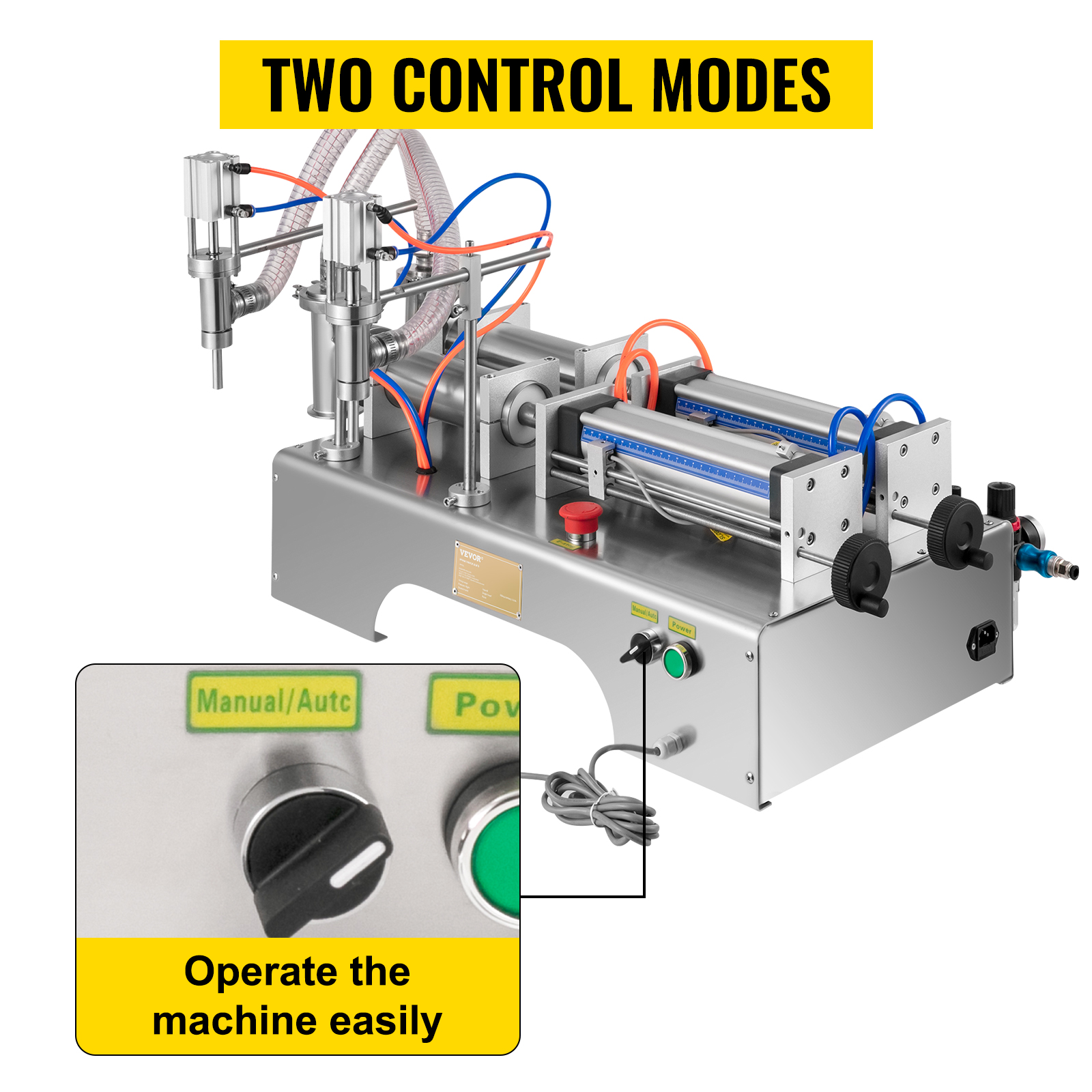

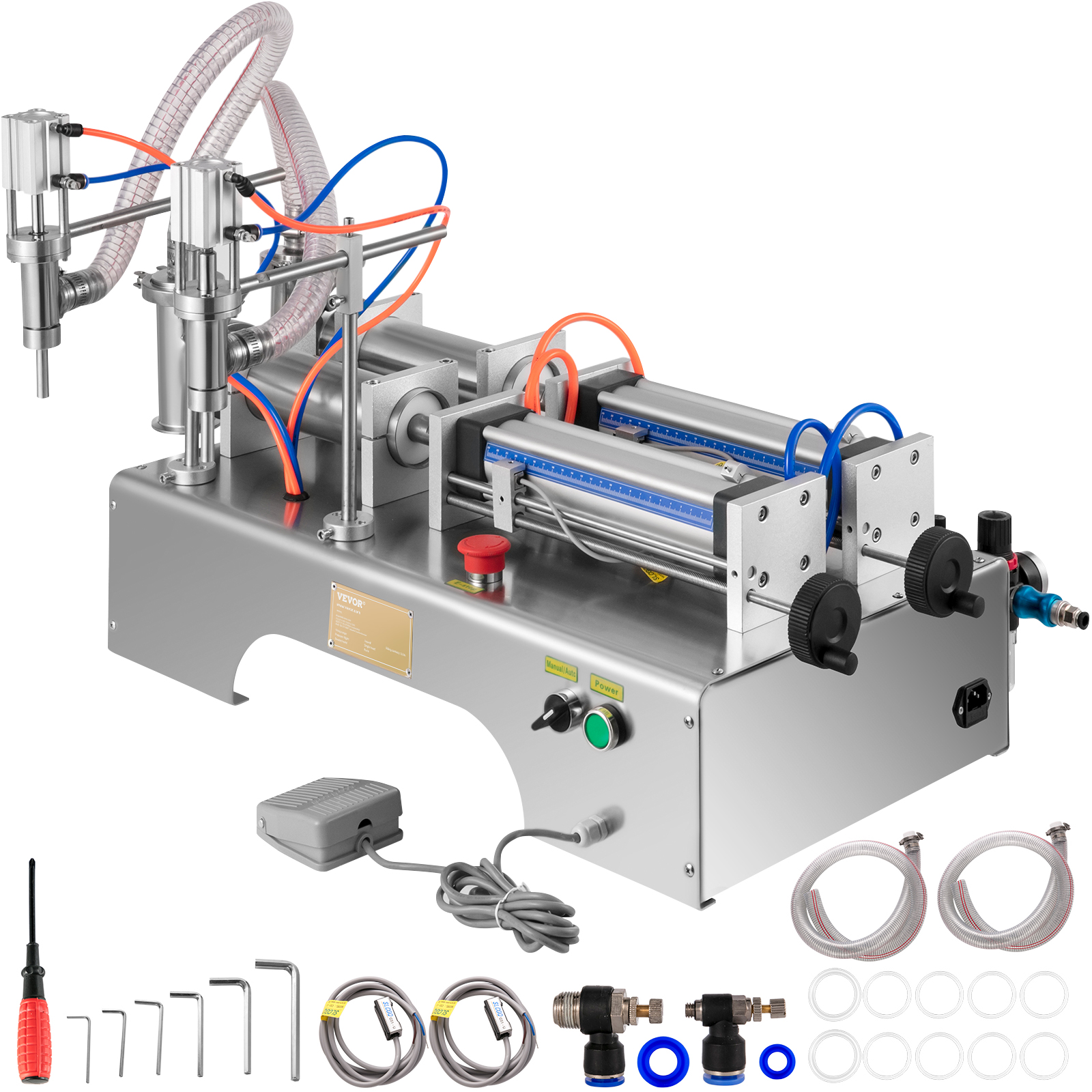

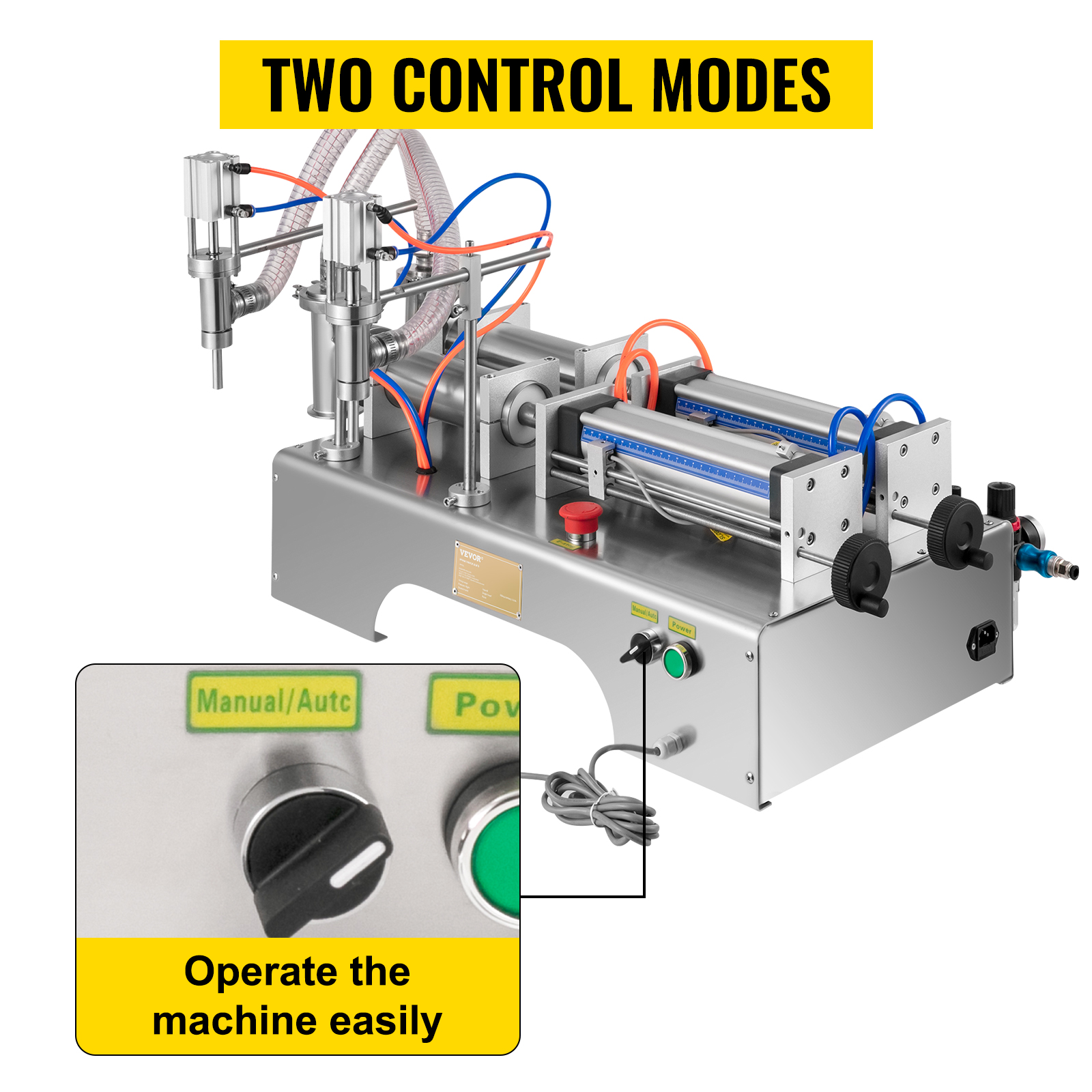

The liquid filler machine 50-500 ml has both auto and manual control modes. Its manual mode allows one filling per pedal press, and auto mode fills continuously. This flexibility caters to different production needs. The air pressure gauge helps monitor pressure changes. It ensures safe operation. You can stop the machine quickly if needed. The control modes are easy to switch between. They allow for efficient and smooth operations. These modes have been designed for ease of use. Therefore, it reduces the learning curve for operators. Efficient operation saves time and boosts productivity.

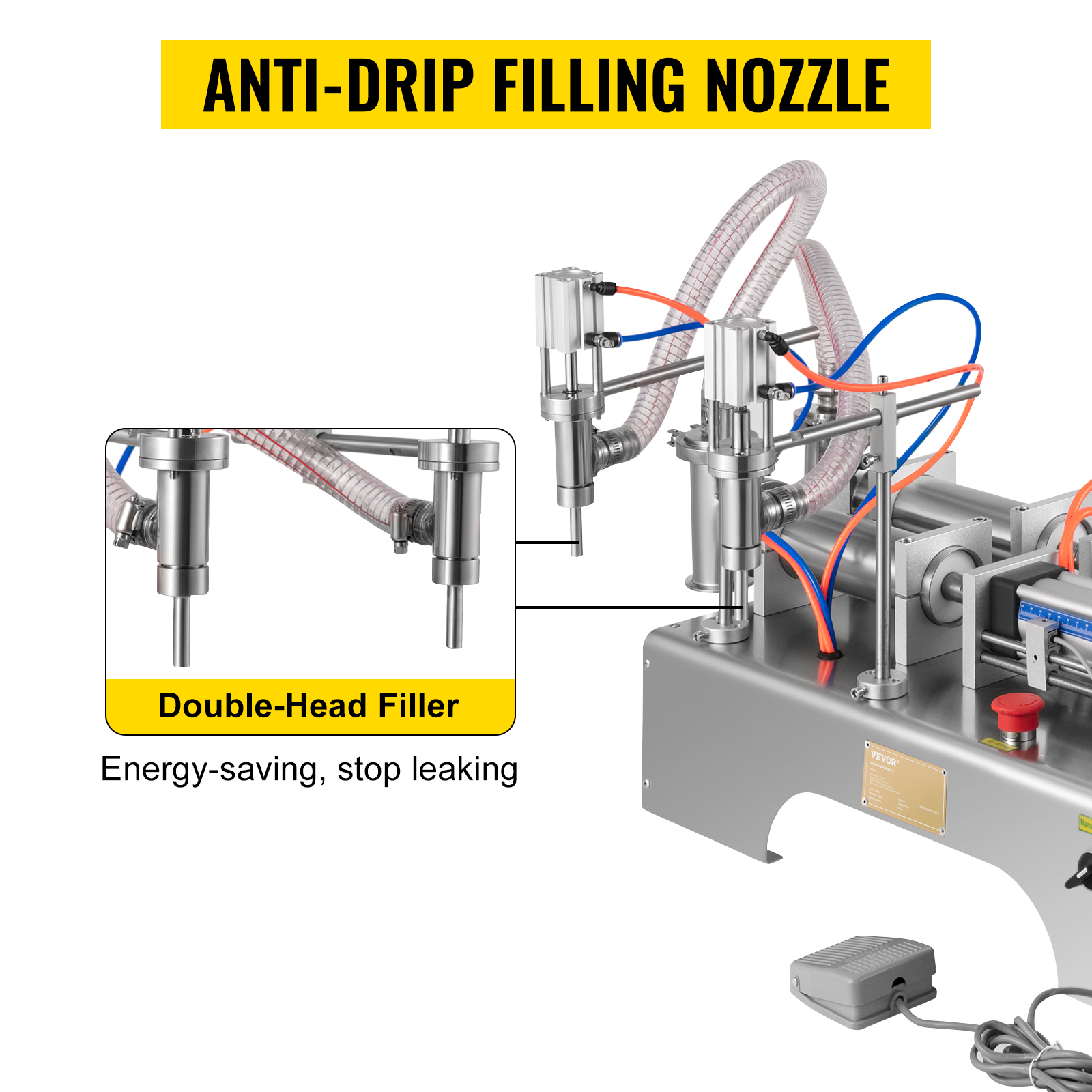

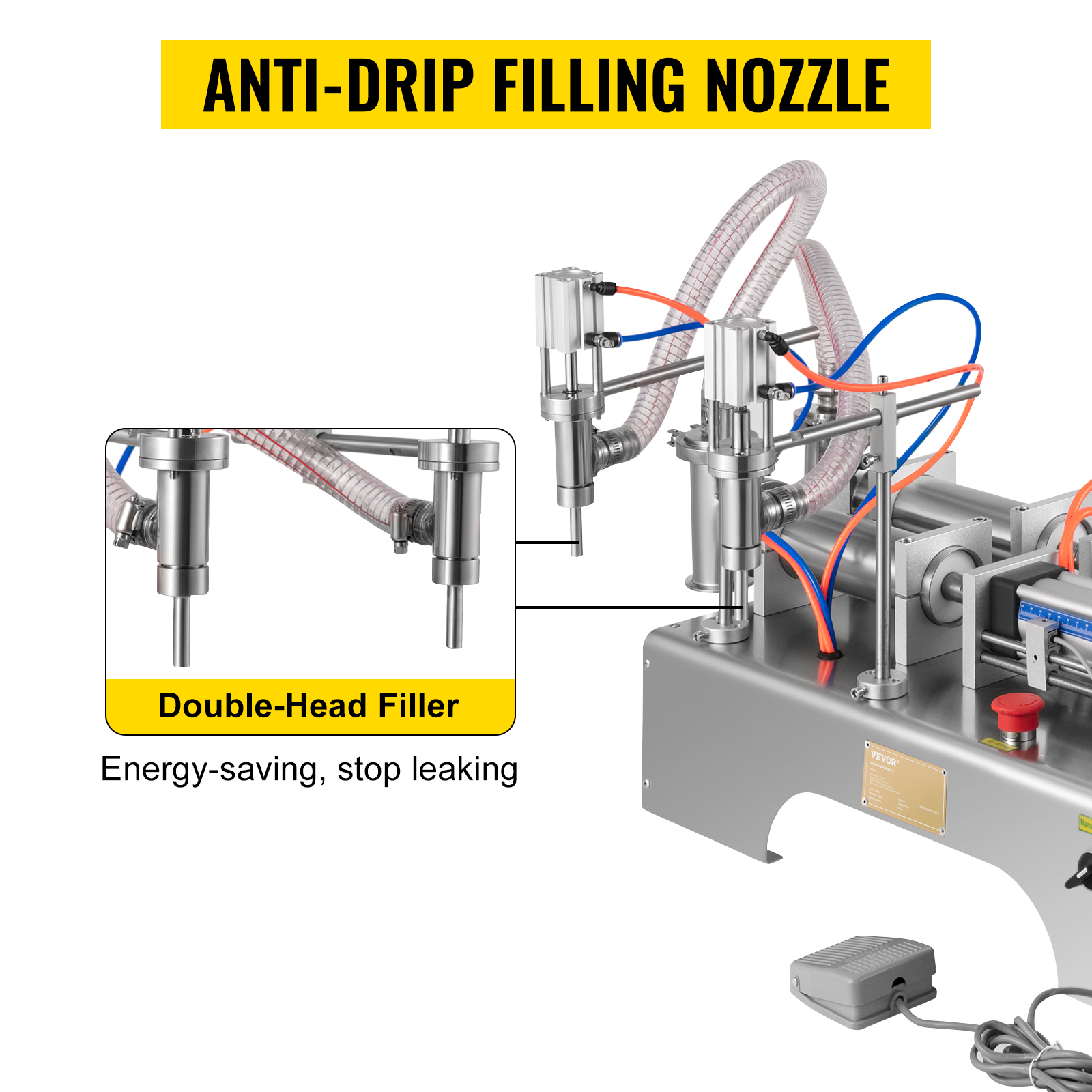

The double-head bottle filler machine is made from 304 stainless steel. This material is food-grade and highly durable. It resists corrosion, rust, acid, and alkali. So, it lasts for a long time. This stainless steel liquid filler saves more liquid during operation. The anti-drip nozzle prevents leaks. The anti-damant stainless steel structure is easy to clean. Therefore, it ensures hygiene. Also, the material helps reduce the need for frequent replacements. Its strong build makes it suitable for heavy-duty use. You can work on your projects without worrying about maintenance for busy production lines.

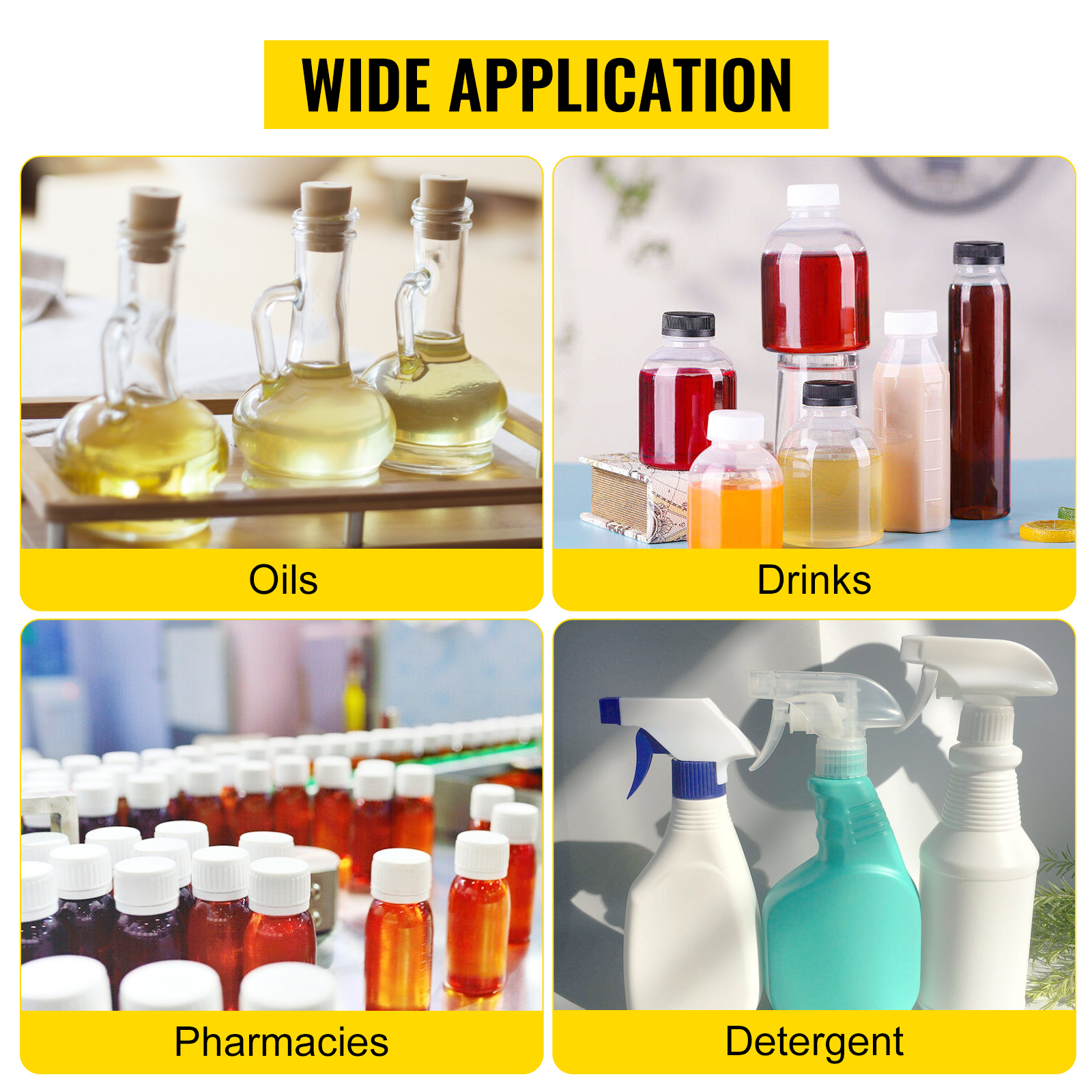

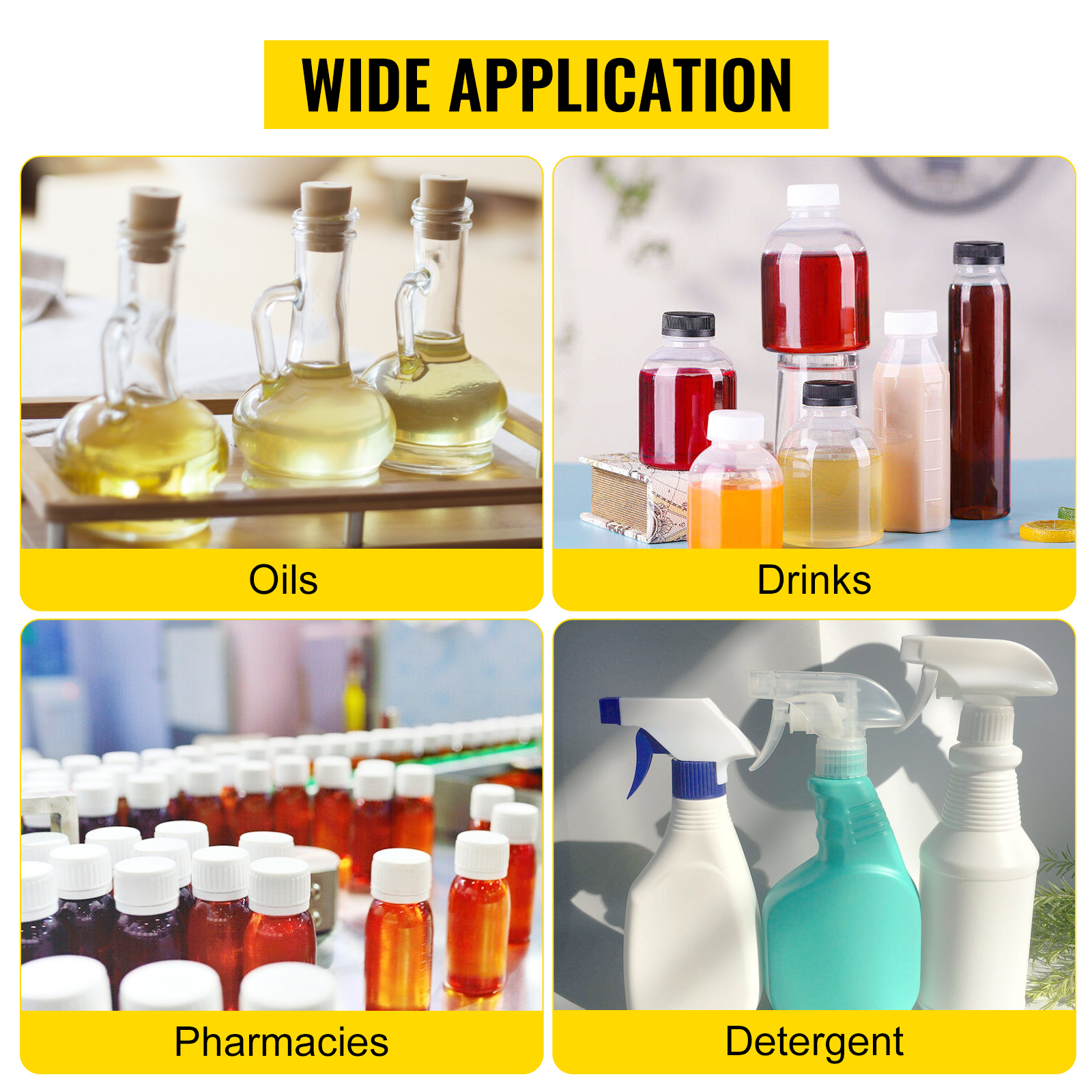

It has a maximum speed of 60 bottles per minute and a volume range of 50-500 ml. You can set the filling volume from 50 to 500 ml. The speed can reach up to 60 bottles per minute. This versatility is useful for various applications. It suits industries like cosmetics, food, and pharmaceuticals. These adjustable settings help customize production. These settings cater to different product types and bottle sizes. Its versatile design ensures it meets diverse needs. This flexibility is beneficial for businesses with varied production demands. This horizontal automatic liquid filler machine can efficiently handle low-viscosity fluids.

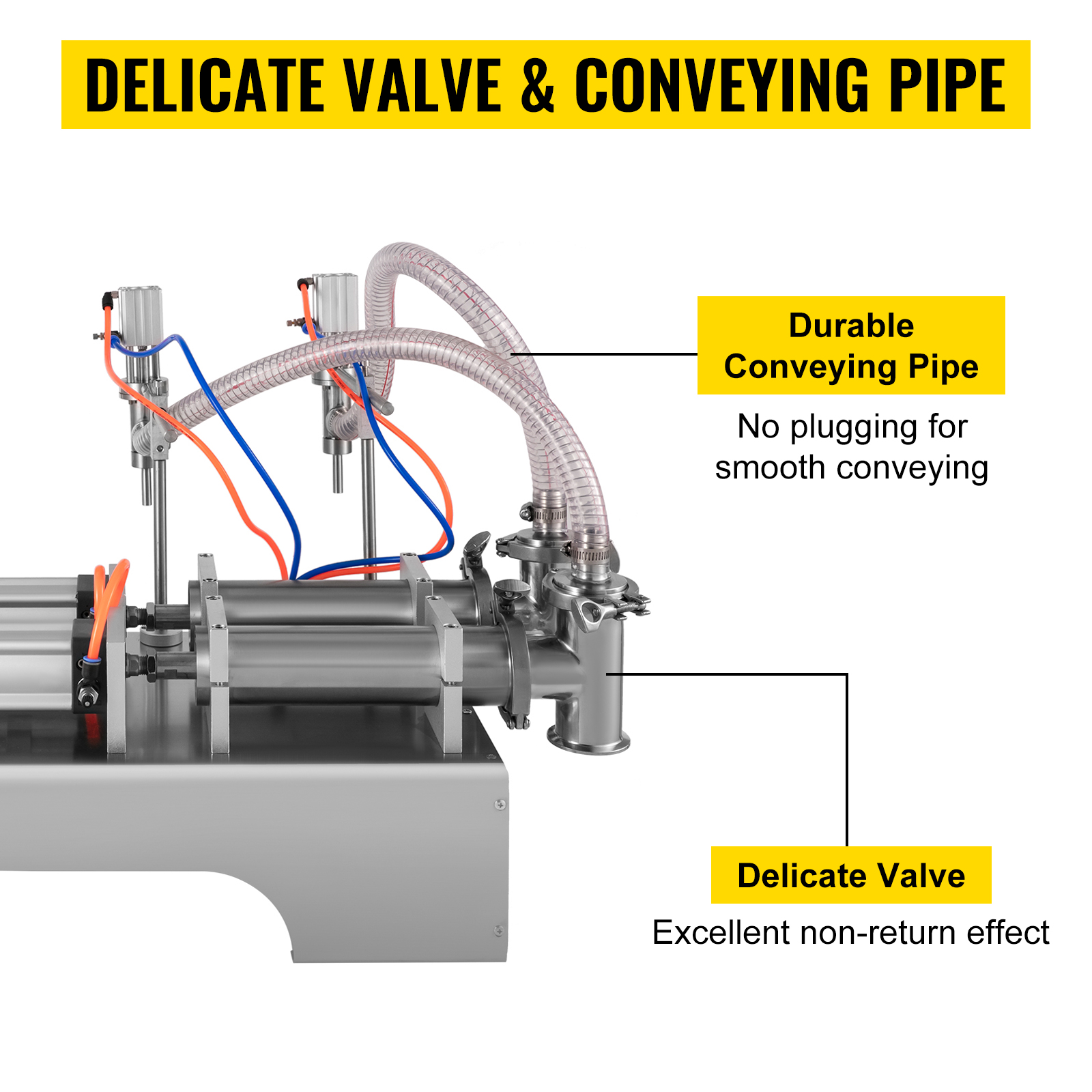

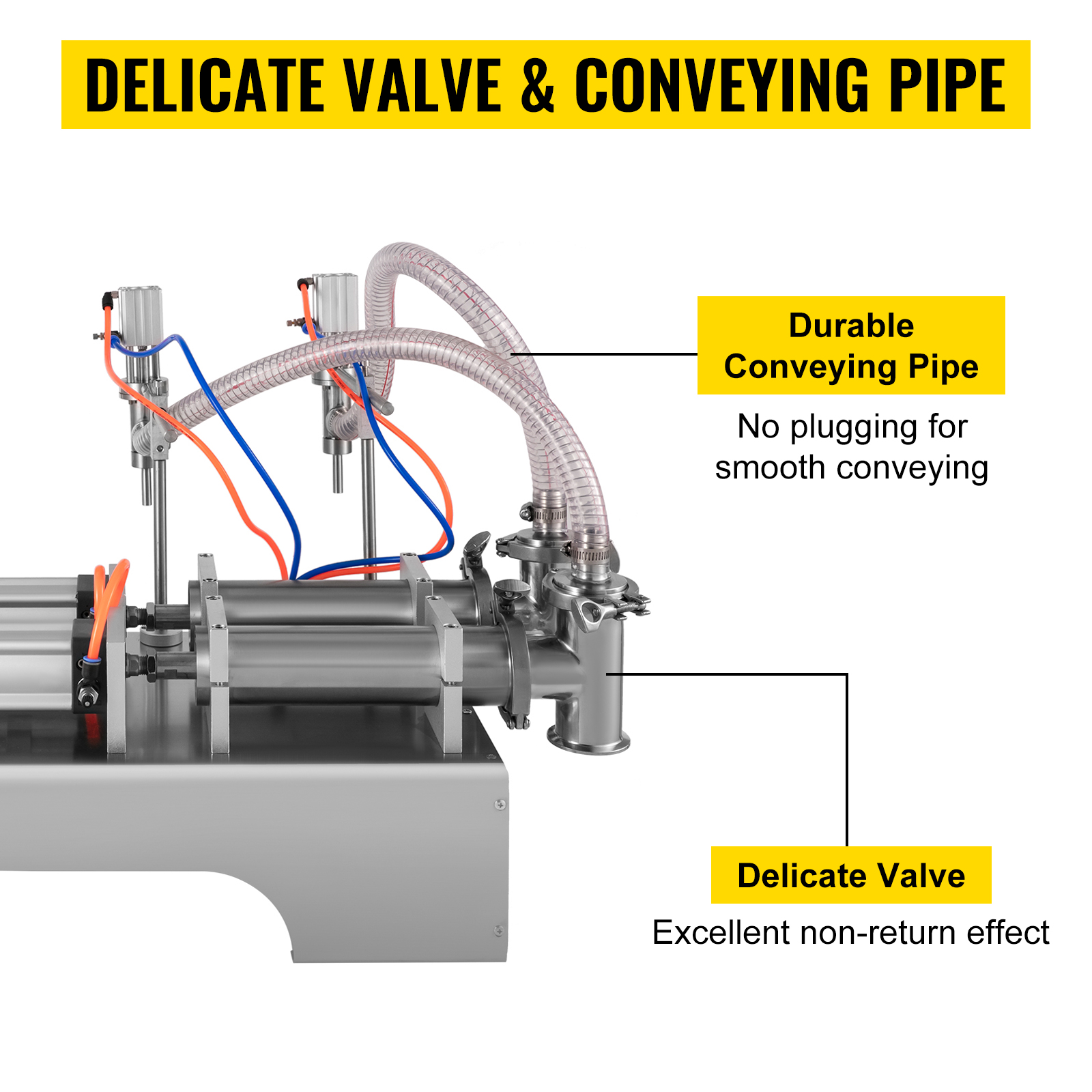

The machine has a well-designed filling device. It includes a hedging pipe and a non-return valve. The soft valve ensures an excellent non-return effect. This smooths out the liquid transfer process. The design ensures that the water flows through the pipe without blockages, which leads to successful filling every time. Its attention to detail enhances the machine's performance. It reduces downtime and maintenance needs. As a result, continuous and reliable operations are achieved. The well-thought-out design caters to efficiency and precision.

The machine is suitable for multiple industries. It is used in cosmetics, food, and pharmaceuticals. It is also suitable for working with pesticides. This machine can serve various products. Its versatile design caters to various product types. This includes low-viscosity fluids and other liquid filling needs, ensuring they fit seamlessly into several production lines.

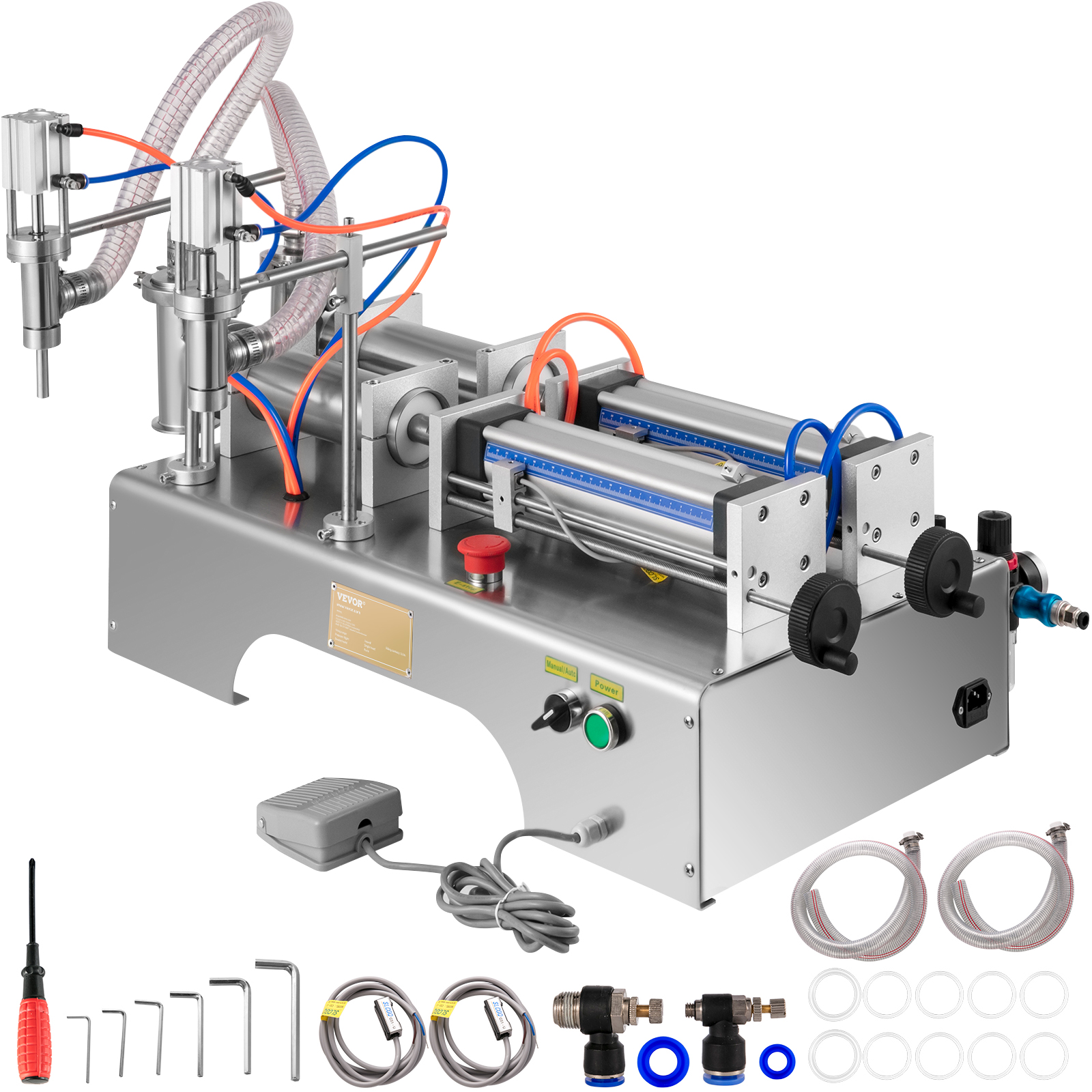

It is easy to set up. It comes with tools and extra parts. This makes the installation process smooth. Once set up, the machine operates quickly. It fills bottles in just five seconds per unit. This high speed boosts productivity. The machine’s design allows for quick operations. This reduces downtime and increases output. The machine's efficiency is beneficial for businesses needing fast production. Its quick setup and operation save time and resources. Therefore, this makes it a cost-effective solution. Its high productivity ensures more units are filled per hour.