Anvil Tools: Essential Equipment for Craftsmen and Blacksmiths

Introduction to Anvil Tools

When it comes to the world of craftsmanship and blacksmithing, few tools hold as much importance and versatility as anvil tools. From shaping metals to forging intricate designs, anvil tools are the backbone of any artisan's workshop. In this comprehensive guide, we'll delve into the various types of anvil tools, their uses, and how they contribute to the creation of stunning metalwork.

Understanding the Importance of Anvil Tools

Anvil tools encompass a wide range of implements designed to aid in metalworking processes. These tools are indispensable for craftsmen and blacksmiths alike, offering precision and control in shaping and forming metals. Whether it's bending, cutting, or punching, anvil tools provide the necessary leverage and support to achieve desired results.

Types of Anvil Tools

1. Hammers and Mallets

Hammers and mallets are fundamental tools in any blacksmith's arsenal. They come in various shapes and sizes, each serving a specific purpose. From shaping hot metal on the anvil to delicate precision work, the right hammer or mallet can make all the difference in the final outcome of a project.

2. Tongs

Tongs are essential for safely gripping and manipulating hot metal during the forging process. They come in a variety of designs, including flat jaw tongs, bolt jaw tongs, and scrolling tongs, each tailored to different types of metalwork.

3. Chisels and Punches

Chisels and punches are used for cutting and shaping metal, as well as creating decorative designs. They range from cold chisels for cutting through cold metal to hot chisels for working on heated metal directly on the anvil.

4. Swages and Fullers

Swages and fullers are tools used for shaping metal by compressing or stretching it against the anvil surface. They come in various shapes and sizes, allowing craftsmen to create intricate patterns and textures on their metalwork.

5. Hardy Tools

Hardy tools are accessories that fit into the hardy hole of the anvil, providing additional support and functionality. They include items such as bending forks, cut-off hardies, and hot cuts, expanding the capabilities of the anvil for various metalworking tasks.

How to Use Anvil Tools Effectively

Proper Grip and Technique

One of the keys to using anvil tools effectively is mastering the proper grip and technique for each tool. This ensures precision and control while minimizing the risk of injury. For example, when using a hammer, maintaining a firm grip and employing the correct striking angle can significantly impact the outcome of the workpiece.

Heat Management

Effective heat management is essential when working with anvil tools, especially during the forging process. Proper heating and cooling of the metal ensure optimal malleability and prevent damage to both the metal and the tools. This requires skill and experience to gauge the temperature accurately and adjust accordingly.

Anvil Maintenance

Regular maintenance of the anvil and accompanying tools is crucial for ensuring longevity and optimal performance. This includes keeping the anvil surface clean and free of debris, as well as inspecting tools for signs of wear or damage. Proper maintenance not only extends the lifespan of the equipment but also enhances the quality of the metalwork produced.

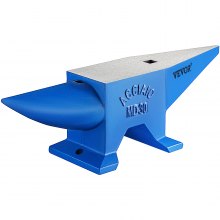

Conclusion: Elevate Your Craftsmanship with Anvil Tools from VEVOR

In conclusion, anvil tools are indispensable assets for craftsmen and blacksmiths seeking to elevate their metalworking endeavors. From shaping and forging to cutting and punching, these tools offer unparalleled precision and control, enabling artisans to bring their creative visions to life. Explore the wide range of high-quality anvil tools available from VEVOR and take your craftsmanship to new heights.

FAQs about Anvil Tools

What are anvil tools used for?

Anvil tools are primarily used in metalworking and blacksmithing processes. They serve various purposes such as shaping, bending, and forming metal objects. Blacksmiths often use anvil tools like hammers, tongs, and chisels to forge metals into desired shapes and sizes. These tools are crucial for manipulating hot metal during the forging process.

What types of anvil tools are available?

There are several types of anvil tools designed for specific tasks in metalworking. Some common examples include anvils, which provide a sturdy surface for shaping metal; hammers, which are used to strike and shape metal on the anvil; tongs, which help hold and manipulate hot metal safely; and chisels, which are used for cutting and shaping metal. Other specialized tools like swages, hardy tools, and fullers are also used in conjunction with anvils for various metalworking techniques.

How do you maintain anvil tools?

Proper maintenance of anvil tools is essential for their longevity and effectiveness. To maintain these tools, it's important to keep them clean and free from rust by regularly wiping them down with a cloth and applying a protective coating of oil. Additionally, inspecting the tools for any signs of wear or damage and repairing or replacing them as needed will help ensure their continued functionality. Proper storage in a dry environment away from moisture and extreme temperatures will also help prevent corrosion and damage to the tools.

Where can I buy anvil tools?

Anvil tools are available for purchase from various sources, including hardware stores, specialty blacksmithing suppliers, and online retailers. Depending on your location and specific needs, you may find a range of options to choose from, including different types of anvils, hammers, tongs, and other related tools. When purchasing anvil tools, it's important to consider factors such as quality, durability, and suitability for your intended use. Researching and comparing different brands and products can help you find the best tools for your metalworking needs.

What safety precautions should I take when using anvil tools?

Using anvil tools, especially in blacksmithing and metalworking, requires certain safety precautions to prevent accidents and injuries. It's essential to wear appropriate personal protective equipment, such as safety glasses, gloves, and closed-toe shoes, to protect against flying sparks, hot metal, and other hazards. Additionally, working in a well-ventilated area and using proper techniques and posture can help minimize the risk of strains and injuries. Always follow proper operating procedures and guidelines for each tool, and never use damaged or defective equipment. Regular training and supervision are also important for safely using anvil tools, especially for beginners or those unfamiliar with metalworking techniques.