Introduction to Belt Grinder Wheels

Belt grinders are indispensable tools in the realms of metalworking, woodworking, and knife making. At the heart of these mighty machines lies a crucial component: the grinder wheels. Let's embark on a journey to explore the diverse world of belt grinder wheels, understanding their types, materials, and how they shape the art of grinding.

Understanding the Significance of Grinder Wheels

Belt grinder wheels serve as the driving force behind the abrasive belts, enabling precise material removal, shaping, and finishing. These wheels come in various shapes, sizes, and materials, each catering to specific grinding needs and preferences.

Types of Belt Grinder Wheels

1. Contact Wheels

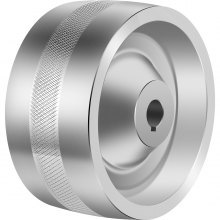

Contact wheels are the primary driving force in belt grinders, exerting pressure on the abrasive belt to facilitate material removal. They come in diverse diameters and hardness levels, offering versatility for various grinding applications.

2. Idler Wheels

Idler wheels support the backside of the abrasive belt, ensuring proper tracking and tension during operation. They come in flat or contoured designs, providing stability and control for consistent grinding results.

3. Drive Wheels

Drive wheels transmit power from the motor to the abrasive belt, enabling smooth and continuous rotation. These wheels often feature a crowned or flat surface to maintain belt alignment and prevent slippage during operation.

Factors to Consider When Choosing Grinder Wheels

1. Wheel Material

Selecting the appropriate wheel material is essential for achieving optimal grinding performance. Common materials include aluminum, steel, rubber, and polyurethane, each offering unique properties such as durability, resilience, and friction.

2. Wheel Size

The size of the grinder wheels, including diameter and width, directly influences grinding capacity and surface coverage. Larger wheels are suitable for heavy-duty grinding tasks, while smaller wheels provide precision and maneuverability for intricate work.

3. Wheel Hardness

Wheel hardness affects the aggressiveness and finish quality of the grinding process. Softer wheels conform to irregular surfaces and reduce heat generation, while harder wheels offer faster material removal and extended wear life.

Popular Grinder Wheel Configurations

1. Flat Platen Setup

A flat platen setup consists of a flat contact wheel and an idler wheel, providing stability and control for flat grinding and precision work. This configuration is ideal for sharpening blades, flattening surfaces, and achieving straight-line grinds.

2. Contact Wheel Setup

A contact wheel setup utilizes multiple contact wheels of varying sizes and hardness levels to accommodate diverse grinding tasks and belt profiles. This configuration offers versatility for contour grinding, hollow grinding, and shaping operations.

Conclusion: Elevating Your Grinding Experience

In conclusion, understanding the diverse world of belt grinder wheels is essential for achieving optimal grinding results and unleashing your creative potential. By selecting the right wheel types, materials, and configurations, you can tailor your grinder setup to suit your specific needs and preferences. Whether you're shaping metal, refining wood, or honing blades, investing in quality grinder wheels will elevate your grinding experience and empower you to tackle any task with precision and finesse.

FAQs about "belt grinder wheels"

What are the different types of belt grinder wheels available?

There are several types of belt grinder wheels available, each serving specific purposes. Some common types include contact wheels, which come in various diameters and hardness levels for different grinding tasks. There are also tracking wheels, tension wheels, and idler wheels, all of which contribute to the performance and stability of the belt grinder. Understanding the role of each wheel type can help you choose the right setup for your grinding needs.

How do I choose the right size and material for belt grinder wheels?

When selecting belt grinder wheels, consider factors such as the intended application and the type of material you'll be grinding. The size of the wheels will affect the speed and contact area of the grinding belt, so choose sizes that align with your specific needs. Additionally, consider the material composition of the wheels; common options include aluminum, steel, and rubber. Each material offers different levels of durability and performance, so choose one that suits your grinding requirements and budget.

Can I use different types of wheels on the same belt grinder?

Yes, it's possible to use different types of wheels on the same belt grinder, depending on your needs and preferences. For example, you may opt for a combination of contact wheels with varying diameters and hardness levels to achieve different grinding effects. Additionally, you can mix and match materials to enhance performance or accommodate specific grinding tasks. Just ensure that the wheels are compatible with your grinder and that you adjust settings accordingly to achieve optimal results.

How do I maintain and replace belt grinder wheels?

Proper maintenance is essential for prolonging the life of belt grinder wheels and ensuring consistent performance. Regularly inspect the wheels for signs of wear, damage, or misalignment, and address any issues promptly. Clean the wheels and grinder components regularly to remove debris and prevent buildup that could affect performance. When replacing wheels, follow the manufacturer's recommendations regarding size, material, and installation procedures to ensure compatibility and safety. With routine maintenance and timely replacements, your belt grinder wheels can continue to deliver reliable grinding results.