The Filling Technology: VEVOR’s Life Changing Tech!

Whether you're a manufacturer in the pharmaceutical industry, owning a business in the food and beverage industry, or a cosmetics producer, we got you covered. As a high-quality filling machine is vital to ensure efficiency, and accuracy in your production line. From filling containers and bottles to packaging pouches and sachets, a high-quality filling machine can optimize your operations and increase rates of productivity.

This guide is the roadmap that will help you understand and choose a suitable filling machine according to your needs. So let's dive in!

Filling machines are machines that exactly fill containers with a defined amount of powder, liquid, or other materials. They are used in manufacturing industries like food, pharmaceuticals, and cosmetics packages. To increase their products efficiently and hygienically, saving time and reducing waste.

Filling machines are manufactured to fill containers with a specific amount of material, those materials could be liquids, powders, or creams, with high speed and accuracy. These machines make the filling process automatic, eliminating the need for manual filling. This saves time and is prone to errors.

Types of Filling Machines

There are several types of filling machines. Each of the filling machines has its specific function and benefits.

These machines are used to fill liquids like water, juice, and chemicals into containers, bottles, and cans. They make sure that the filling is done accurately, minimizing spills and waste.

Powder Filling Machines

Powder-filling machines are designed for powders used in pharmaceuticals, cosmetics, and food products. These machines fill specific amounts into containers, making sure that the quality of the product is good.

Cream Filling Machines

Cream fill machines are used to fill creams in products like pharmaceuticals, and cosmetics. They are also used in food products like jars, tubes, or containers to fill the desired food. Making sure of product integrity and texture.

Aerosol Filling Machines

They are used for filling aerosol cans with sprays, foams, and gases. These machines make sure that the filling and crimping are precise. By maintaining product quality.

These machines are used to fill various liquids, powders, or creams into bottles. They offer flexibility and efficiency in packaging.

Can Filling Machines

These machines are designed for filling cans with liquids, powders, or creams. These machines offer hermetic sealing, maintaining product freshness.

Jar Filling Machines

These machines are used to fill jars with liquids, powders, or creams. They are often used in the cosmetics, food, and pharmaceutical industries.

Pouch Filling Machines

They are designed for filling pouches with powders, liquids, or creams. These machines offer versatility in packaging solutions.

Sachet Filling Machines

These machines are used to fill sachets with specific amounts of powders, liquids, or creams. They are ideal for single-serve packaging.

Choosing the Suitable Filling Machines: Key Considerations

Each filling machine is classified according to its specific functions and use. While selecting the suitable filling machines following are the factors that you should consider to buy suitable filling machines.

Filling Speed and Capacity

The capacity and filling speed of the machine should match the requirements of production. A filling machine with a capacity of 100-200 bottles per hour is suitable for household juice, whereas a machine that can fill 1,000-2,000 bottles per hour is sufficient for large commercial users.

Product Protection and Handling

The machine should be designed in a way that it can handle the specific product with care, lessening the risk of damage or contamination. For instance, a filling machine for pharmaceuticals should have features like sterilization, vacuum filling, and precise dosing to ensure product quality.

Integration and Automation

The filling machine should be able to integrate with existing equipment and production lines, offering automation features to minimize human efforts. For example, a filling machine for a cosmetics company should be able to integrate with their labelling and capping machines. Also, look for machines that have features like automatic container detection and filling parameter control.

Optimizing your Filling Process: Vevor’s Filling Machines Superior Features

Superior features make VEVOR’s filling machines an excellent choice for household and commercial use. Following are the superior features of VEVOR’s filling machines.

Precise Filling Technology

VEVOR's filling machines are made of advanced filling technology to ensure accurate filling quantities, and waste, and eliminate errors. This feature guarantees definite and exact filling, even at high speeds.

Advanced Automation

VEVOR's filling machines have advanced automation features. Advanced features like automatic filling, container detection, and capping. This reduces labour costs and increases efficiency. This feature ensures uninterrupted production, minimizing downtime and maximizing output.

Our Top Filling Machines Models

VEVOR’s filling machines offer high-quality filling. Our top picks are designed with high quality and technology. This reduces labour costs and efficiency. We offer the latest technology filling machines at unbeatable rates.

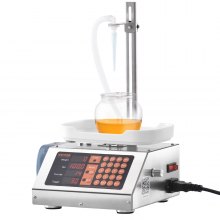

VEVOR Automatic Liquid Sealing Machine Food-Grade Stainless Steel Weighing Filling Machine 5-160 ml

This VEVOR filling machine is suitable for small to medium-sized businesses in the food, cosmetic, and pharmaceutical industries. It is made of food-grade stainless steel construction and an exact weighing system which makes it perfect for filling high-value products. It's also easy to maintain and clean. This is the plus point making it a great addition to any production line.

Testimonial

I was amazed by the accuracy and speed of this machine! It fills our 50ml bottles precisely and easily, and the stainless steel construction is top-notch. The support team at VEVOR has also been very cooperative. Highly recommend it!" - Emily R., Happy Customer

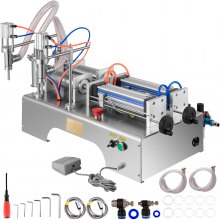

VEVOR Horizontal Pneumatic Liquid Filling Machine 10-300ML

This VEVOR filling machine is ideal for filling creams, pastes, and liquid products. This machine is perfect for industries like cosmetics, food, and pharmaceuticals. Its pneumatic system makes sure that filling is done precisely, while the 30L hopper and horizontal design make it easy to use and clean.

Testimonial

This machine has changed our production line! The pneumatic filling system is quick and exact, and the horizontal design makes it easy to clean and load. The support team at VEVOR has been fantastic. Highly recommend it!" - John D.

FAQs

How do I choose a filling machine?

Consider the nature of the product and its impact on machine type. For example, for the filling of dense and thick cream, a cream filling machine is suitable.

Which tool is used for filling?

A filling knife may look a bit scraper but the main difference is its versatility in blades.

A type of filling machine that is operated by hand rather than these semi-automatic or automatic operations.

Conclusion

Filling machines are crucial if you are seeking to improve your filling process quality in your product line. VEVOR offers high-quality, efficient filling machines at unbeatable rates.