The Ultimate Guide to Liquid Filling: Solutions for Every Need

Whether you are a budding entrepreneur in the beverage industry, a pharmaceuticals expert, or a crafts enthusiast dealing with liquids, understanding the nuances of liquid filling is essential. The process, seemingly straightforward, involves a plethora of choices and considerations. This guide delves deep into the world of liquid filling, providing insights and solutions tailored for various needs and industries. Prepare to embark on a fluid journey that will enhance the efficiency and quality of your liquid products.

Understanding Liquid Filling

What is Liquid Filling?

Liquid filling is a critical process in the manufacturing sector, involving the transfer of liquid products into containers or packages. This process is not only pivotal for maintaining the product's integrity but also for ensuring accuracy in quantity, thereby upholding the product's value in the market. From beverages and pharmaceuticals to household chemicals and beauty products, liquid filling plays a vital role across various industries.

The Importance of Choosing the Right Equipment

Selecting the appropriate liquid filling machinery is paramount. It influences not just the speed and efficiency of your production line but also the quality of your final product. Factors such as viscosity, container types, and production scale play a significant role in this decision-making process.

Gravity vs. Pressure Fillers

Gravity fillers are ideal for thin, free-flowing liquids. They rely on the force of gravity to fill containers, making them a cost-effective option. On the other hand, pressure fillers are suited for thicker, more viscous liquids or products with particulates, using pressure to ensure a consistent fill volume.

Piston Fillers for Viscous Products

Piston fillers are the go-to for highly viscous products or those with large particulates. Their precision and versatility in handling a wide range of product types and volumes make them indispensable in many settings.

Overflow Fillers for Consistent Fill Levels

Overflow fillers are designed to deliver uniform fill levels across containers, making them perfect for products where fill level is a critical aesthetic or regulatory requirement. These machines are particularly favored in the cosmetics and food and beverage industries.

Choosing the Right Liquid Filling Machine

Assessing Your Needs

Understanding your product's characteristics, the type of containers you will be using, and your production goals are crucial steps in selecting the right liquid filling machine. It's about striking the perfect balance between efficiency, cost, and the quality of the end product.

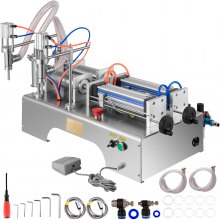

Considering Production Scale

Your production volume significantly impacts the choice of machinery. While manual or semi-automatic machines may suffice for smaller operations, larger-scale productions demand fully automated lines to meet higher output requirements efficiently.

Material Compatibility

Ensuring that the materials used in your liquid filling machine are compatible with your product is vital. This not only prevents contamination but also safeguards the machinery from potential damage caused by corrosive substances.

Customization and Flexibility

In a dynamic market, the ability to customize and adapt your machinery to different products and container sizes is invaluable. Opt for machines that offer flexibility and ease of adjustment to stay ahead in the competitive landscape.

Maximizing Efficiency in Liquid Filling

Automated Systems for Enhanced Productivity

Leveraging automated filling systems can significantly enhance your production line's efficiency. These systems streamline operations, reduce labor costs, and minimize errors, ensuring a swift and consistent filling process.

Maintaining Equipment for Longevity

Regular maintenance and proper care of your liquid filling machines are imperative for their longevity and performance. A well-maintained machine ensures uninterrupted production and reduces the risk of costly downtime.

Training and Support

Investing in comprehensive training for your staff on the operation and maintenance of the liquid filling machinery can pay dividends. Additionally, choosing a supplier that offers robust support and service can help resolve any potential issues swiftly, ensuring minimal disruption to your operations.

Trends in Liquid Filling Technology

Sustainability and Eco-Friendliness

The trend towards sustainability has reached the liquid filling industry, with an emphasis on eco-friendly materials and energy-efficient machinery. Adopting such technologies not only helps the environment but can also lead to cost savings and enhanced brand image.

Smart and Connected Machinery

The integration of IoT (Internet of Things) technology in liquid filling machines is revolutionizing the industry. Smart, connected devices offer real-time monitoring and control, optimizing the production process and facilitating predictive maintenance.

Innovations in Packaging

Innovations in packaging materials and designs are continually emerging, influencing liquid filling processes. Adapting to these changes requires versatile and adaptable filling machinery capable of handling a variety of container types and sizes.

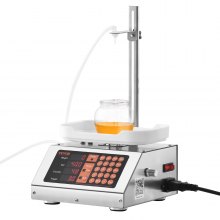

VEVOR: Your Partner in Liquid Filling Excellence

Why Choose VEVOR?

VEVOR stands at the forefront of liquid filling technology, offering a comprehensive range of machines designed for efficiency, reliability, and precision. With a focus on innovation and quality, VEVOR is committed to providing solutions that meet the diverse needs of its clients, ensuring your investment is matched with unmatched performance and support.

Take the Next Step

Embarking on your liquid filling journey or aiming to enhance your current operations? VEVOR offers expert advice, state-of-the-art equipment, and comprehensive support to ensure your success. Contact us today to discover how we can help you achieve your production goals and elevate your business to new heights.

Conclusion

Mastering the Art of Liquid Filling

The world of liquid filling is intricate and varied, with solutions tailored for every conceivable need and industry. From understanding the basics to choosing the right equipment and keeping abreast of the latest trends, there is much to consider. However, with the right knowledge, equipment, and partner, you can achieve a seamless, efficient, and productive operation that not only meets but exceeds expectations.

Choosing VEVOR for Your Liquid Filling Needs

VEVOR's dedication to quality, innovation, and customer support makes it the ideal partner in your liquid filling journey. Whether you're just starting out or looking to upgrade your existing setup, VEVOR's range of liquid filling solutions is designed to offer reliability, efficiency, and precision, ensuring your business thrives in a competitive market.

Elevate Your Liquid Filling Process with VEVOR

Ready to take your production to the next level? With VEVOR, you're choosing a partner committed to excellence and innovation in the liquid filling industry. Explore our products and services today, and let us help you find the perfect solution to meet your needs. Together, we can achieve remarkable results and ensure the success of your liquid filling endeavors.

Get Started Today

Don't let the complexities of liquid filling deter you. With the right approach and support, you can navigate this challenging yet rewarding process with confidence. Contact VEVOR today to learn more about how our products and expertise can help streamline your operations, enhance product quality, and boost your bottom line. Your journey towards liquid filling excellence begins here.