Elevate Your Warehouse Efficiency: Discover the Ideal Pallet Puller

Embrace Efficiency with a Top-Quality Pallet Puller

In today’s fast-paced logistics and warehousing environments, the importance of efficient, safe, and reliable handling of goods cannot be overstressed. An indispensable tool in this quest for operational excellence is the pallet puller. This essential equipment aids in the smooth, easy, and safe movement of pallets, especially those positioned deep within trucks or in difficult-to-reach spots.

Understanding Pallet Pullers: Your Path to Enhanced Productivity

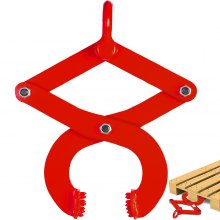

Pallet pullers are not just tools; they are your partners in streamlining warehouse operations. By clamping onto the edges of pallets, they allow forklifts and other lifting devices to retrieve them without entering the transportation vehicle, minimizing the risk of injury and damage to goods.

The Mechanics Behind the Magic: How Pallet Pullers Work

Discover how these simple yet powerful devices can transform your workflow. From their robust construction to the unique mechanisms such as scissor action, cam action, and chain link extensions, understand the science behind the tool that ensures the safety and integrity of your cargo.

Varieties to Venerate: Types of Pallet Pullers

Dive into the diverse world of pallet pullers, exploring various types designed for different pallet materials and warehouse needs. Whether your operations require single or double scissor designs, jaw capacities, or specific types of grips, this section helps you navigate your options.

Selecting the Supreme Pallet Puller: A Buyer’s Guide

Embark on a journey to select the perfect pallet puller that aligns with your warehouse demands and budget. Assess factors like material, weight capacity, jaw opening size, and ease of use to ensure you make an informed decision that will elevate your operational efficiency.

Criteria for the Perfect Choice: Features to Consider

Fine-tune your selection process with a detailed look at what makes a pallet puller stand out. Consider durability, ease of operation, compatibility with different pallet types, and maintenance requirements to secure a tool that delivers value beyond its cost.

Hear from the Heroes: Customer Reviews and Success Stories

Gain confidence in your choice by exploring real-life testimonials and case studies from businesses like yours. Learn how the right pallet puller has transformed their operations, reduced manual labor, and increased safety.

Maximizing Your Investment: Tips for Pallet Puller Maintenance

Unlock the secret to prolonging the life of your pallet puller with essential maintenance tips. Regular checks, proper storage, and immediate repairs can prevent downtime and extend the efficiency and reliability of your tool.

Safety First: Ensuring Proper Use of Your Pallet Puller

Prioritize safety in your operations by adhering to best practices for using pallet pullers. This section covers essential safety tips, proper handling techniques, and common mistakes to avoid, ensuring a safe environment for your workforce.

Revolutionize Your Warehouse Layout with Pallet Pullers

Discover the strategic advantages of integrating pallet pullers into your warehouse design. From optimizing space to enhancing flow and accessibility, learn how this tool can play a pivotal role in your layout planning.

Integration and Compatibility: Working with Existing Systems

Ensure your pallet puller investment seamlessly integrates with your current warehouse setup. Consider compatibility with forklifts, existing pallet types, and storage configurations to enhance rather than hinder your workflow.

Unveiling the Cost-Benefit Analysis: Is a Pallet Puller Worth It?

Dive into a comprehensive analysis of the costs versus benefits of investing in a pallet puller. Understand the potential return on investment through improved efficiency, reduced labor costs, and minimized product damage.

Overcoming Obstacles: Addressing Common Challenges

Acknowledge and prepare for potential challenges in implementing pallet pullers in your operations. This section offers solutions to common issues such as space constraints, employee resistance, and initial setup costs.

Empowering Your Team: Training for Optimal Pallet Puller Use

Invest in your most valuable asset – your team. Discover effective training strategies and resources to ensure your staff is proficient, confident, and safe in using pallet pullers, thereby maximizing the tool’s potential.

Continuous Improvement: Updating Skills and Knowledge

Stay ahead of the curve by encouraging ongoing learning and improvement in pallet puller use. Explore avenues for advanced training, refresher courses, and staying updated with industry best practices.

Beyond the Basics: Advanced Pallet Puller Techniques and Innovations

Elevate your knowledge with advanced techniques and the latest innovations in pallet puller technology. From automated systems to smart features, see how these advancements can further optimize your warehouse operations.

Future Trends: The Evolution of Pallet Pullers

Peer into the future of pallet pulling technology and how it is set to revolutionize warehouse operations. Anticipate upcoming trends and how to prepare your business to adopt new and improved solutions.

Your Next Step: Selecting the Ideal Pallet Puller for Your Needs

Synthesize the information gathered to make a well-informed decision on the best

pallet puller for your warehouse. Consider all factors, from operational needs to budget constraints, to select a tool that meets your specific requirements.

The VEVOR Difference: Elevate Your Efficiency with Our Premium Pallet Pullers

Discover how VEVOR’s range of high-quality pallet pullers can transform your warehouse operations. From superior materials to innovative designs, learn why VEVOR stands out as the preferred choice for businesses aiming for operational excellence.

Why Choose VEVOR: Unmatched Quality and Service

Delve into the VEVOR advantage, highlighting our commitment to quality, customer service, and innovation. Understand how our pallet pullers provide not just a tool, but a comprehensive solution to your operational challenges.

Conclusion: The Time to Act is Now

Conclude with a persuasive call to action, encouraging the reader to take the next step towards operational efficiency by choosing the perfect pallet puller. Highlight the importance of investing in quality equipment and the long-term benefits of enhancing workplace safety and productivity.

Take the Leap with VEVOR

Encourage immediate action with a direct invitation to explore VEVOR’s selection of pallet pullers. Emphasize the transformative impact the right tool can have on their operations and invite them to join the community of satisfied customers who have elevated their efficiency with VEVOR.

FAQs about Pallet Pullers

What Is a Pallet Puller and How Does It Work?

A pallet puller is a tool designed to move pallets within a warehouse or loading area, especially when they're too far for a forklift to reach directly. It works by clamping onto the wooden or plastic slats of a pallet. Once secure, a forklift or another hauling vehicle can pull the pallet to a more accessible location. The mechanism typically involves a gripping component, such as jaws or hooks, which lock onto the pallet, and a chain or rope that connects to the forklift.

Can Pallet Pullers Be Used on All Types of Pallets?

Pallet pullers are versatile, but they are best used with certain types of pallets. They are most effective on wooden and plastic pallets that have strong and secure slats or openings. Metal pallets can also be moved with pallet pullers, but it’s essential to check the puller’s specifications to ensure it can handle the pallet's weight and material. It's not recommended to use pallet pullers on damaged or weak pallets as this could lead to breaking or further damage.

What Are the Key Features to Look for When Choosing a Pallet Puller?

When selecting a pallet puller, key features to consider include the jaw opening size, weight capacity, and the type of material it's made from. A larger jaw opening allows for a wider range of pallet sizes to be accommodated. The weight capacity should exceed the heaviest pallet you plan to move. Additionally, look for durable materials like steel to ensure longevity and resilience. Other factors might include ease of use, safety features, and whether it has a scissor or cam action mechanism for better grip.

How Do I Maintain My Pallet Puller?

Maintaining a pallet puller involves regular inspections for signs of wear or damage, especially on the gripping mechanisms and chain or rope. Cleaning it after use to remove debris and dust can prevent malfunctioning. It's also essential to lubricate moving parts periodically to ensure smooth operation. Store the pallet puller in a dry, clean place to prevent rust and corrosion. If any part is damaged or excessively worn, replace it immediately to maintain safety and efficiency.

Are There Any Safety Precautions to Consider When Using a Pallet Puller?

Safety is paramount when using a pallet puller. Always wear appropriate personal protective equipment, such as gloves and safety shoes. Before use, check the pallet for stability and strength to ensure it can withstand the pulling force. Make sure the area is clear of obstacles and other workers to prevent accidents. When attaching the puller, ensure it is securely fastened to the pallet. Never exceed the recommended weight limit, and always use the pallet puller as directed by the manufacturer. Regular training and refreshers for all operators can significantly reduce the risk of workplace incidents.