Unraveling the Mysteries of Pipe Bending: Your Go-To Resource

Introduction to Pipe Bending

Welcome to the fascinating world of pipe bending, a crucial technique used in countless industries worldwide. Whether you're a professional plumber, an ambitious DIY enthusiast, or someone involved in the automotive, construction, or manufacturing sectors, understanding the intricacies of pipe bending can significantly enhance your projects. This guide aims to demystify the process, introduce you to various types of pipe benders, and help you select the ideal tool for your needs.

Why Bend Pipes?

The Art and Necessity of Bending Pipes

Bending pipes allows for the creation of custom shapes and angles, essential in numerous applications from household plumbing to intricate industrial designs. This section explores the importance of precision and creativity in bending pipes, ensuring functionality and aesthetic appeal in your projects.

Material Matters: Choosing the Right Pipes

Not all pipes are created equal. Here, we delve into the different materials used in pipe manufacturing, such as copper, steel, and PVC, and discuss how the material properties affect the bending process.

Types of Pipe Benders

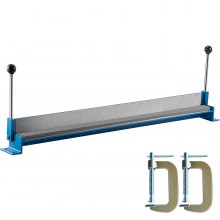

Manual Pipe Benders: Pros and Cons

Discover the simplicity and precision offered by manual pipe benders, perfect for small-scale projects or where intricate control is required. We'll discuss the advantages and limitations to help you assess if a manual bender fits your project needs.

Hydraulic Pipe Benders: Power and Performance

For those requiring more force and efficiency, hydraulic pipe benders offer a robust solution. Learn about their operation, ideal use cases, and why they might be the best choice for your heavy-duty bending tasks.

Electric and Programmable Benders: The Future of Pipe Bending

Electric and programmable pipe benders represent the pinnacle of bending technology. This section outlines their features, benefits, and suitable applications, illustrating how they can streamline your projects.

Selecting the Perfect Pipe Bender

Understanding Your Project Requirements

Before choosing a pipe bender, it's crucial to understand your project's specific needs. This part provides insights into assessing your project requirements and how they align with different types of benders.

Features to Look For in a Pipe Bender

Discover the essential features that make a great pipe bender, from versatility and durability to precision and ease of use. Learn what to look for to ensure you get the best tool for your work.

Brand Matters: Why Choose VEVOR Pipe Benders

VEVOR stands out in the world of pipe benders for its quality, reliability, and customer service. Find out why choosing a VEVOR pipe bender could be the best decision for your bending needs.

Pipe Bending Techniques and Tips

Mastering the Basics: Fundamental Bending Techniques

Learn the fundamental techniques of pipe bending to ensure a smooth and accurate process. This section provides step-by-step instructions and expert tips to help you achieve perfect bends every time.

Advanced Bending Techniques for Professionals

For those looking to take their bending skills to the next level, this part explores advanced techniques and strategies to tackle complex bending projects with confidence.

Common Mistakes and How to Avoid Them

Even seasoned professionals can make mistakes. Here, we discuss the most common pitfalls in pipe bending and provide advice on how to avoid them, ensuring flawless results in your projects.

Maintenance and Safety

Keeping Your Pipe Bender in Top Condition

Regular maintenance is key to the longevity and performance of your pipe bender. Learn about routine upkeep, cleaning, and storage practices to keep your tool in optimal condition.

Safety First: Operating Pipe Benders Safely

Safety should never be an afterthought. This section emphasizes the importance of safety measures and best practices while operating pipe benders, protecting you and those around you.

Creative Projects and Applications

Innovative Uses for Bent Pipes

Discover the myriad of creative and practical applications for bent pipes, from artistic sculptures to functional furniture. This part aims to inspire your next project with examples and ideas.

Real-Life Success Stories

Read about individuals and businesses that have successfully implemented pipe bending techniques in their projects, providing real-world inspiration and demonstrating the versatility of this skill.

Troubleshooting and FAQs

Overcoming Common Bending Challenges

Encounter a problem? This section addresses common challenges in pipe bending and offers practical solutions to help you overcome them efficiently.

Your Questions Answered

We've compiled a list of frequently asked questions about pipe bending, providing clear, concise answers to help clarify any uncertainties and enhance your understanding.

Conclusion: Embrace the Bend with VEVOR

The Ultimate Partner for Your Bending Projects

In conclusion, mastering the art of pipe bending opens up a world of possibilities for your projects. Whether you're a novice or a seasoned professional, VEVOR's range of pipe benders provides the quality and versatility you need to achieve precise, efficient results.

Take the Next Step with VEVOR

Ready to embark on your pipe bending journey? Visit VEVOR today to explore our extensive selection of pipe benders and find the perfect tool for your needs. Embrace the bend and transform your creative visions into reality with VEVOR's reliable and innovative solutions.

Start Your Pipe Bending Adventure Today

Don’t let the complexities of pipe bending deter you. With the right tool and a bit of practice, you can achieve professional-quality bends and bring your projects to life. Whether for home improvement, artistic creation, or industrial construction, a VEVOR pipe bender is your steadfast companion in navigating the bends and curves of your creative endeavors.

Why Wait? Discover the VEVOR Difference

Dive into the world of pipe bending with confidence. VEVOR's commitment to quality, customer satisfaction, and innovation ensures that you have the best tools at your disposal. Explore our collection, find the perfect match for your bending needs, and start shaping the future one bend at a time.

Join Our Community

Become part of a growing community of professionals, hobbyists, and enthusiasts who share your passion for pipe bending. Gain access to exclusive tips, tutorials, and support to enhance your skills and maximize your project's potential.

Share Your Success

We love seeing our customers thrive and excel in their projects. Share your success stories and project photos with us, and inspire others in the community. Let’s celebrate the art of pipe bending together!

Final Thoughts: The Art of Bending

As we conclude this comprehensive journey into the world of pipe bending, we hope you feel inspired and equipped to tackle your next project with enthusiasm and expertise. Remember, the art of bending is not just about manipulating metal; it's about shaping possibilities, solving problems, and creating something extraordinary.

Embrace Your Creativity with VEVOR

Every bend in a pipe represents a curve in your creative journey. With VEVOR's support, embrace the challenges, revel in the process, and take pride in the outcomes. Your pipe bending adventure starts here. Shape your world with VEVOR – where precision meets passion.

Thank you for choosing VEVOR as your guide in the captivating realm of pipe bending. We're excited to see where your creativity takes you and how our tools can help pave the way to your success. Happy bending!

FAQs about Pipe Bender

What Types of Pipe Benders Are There?

Pipe benders come in various types, each suited to different materials, bend angles, and project scales. The most common types include manual, hydraulic, and electric benders. Manual benders are great for smaller projects and softer materials. Hydraulic benders offer more power and are suitable for thicker, more rigid materials. Electric benders are the most advanced, allowing for precise and repetitive bends, ideal for larger-scale or industrial projects.

How Do I Choose the Right Pipe Bender for My Project?

Selecting the right pipe bender depends on several factors including the type of pipes you're working with (material, diameter, wall thickness), the complexity of the bends, and the project's scale. For simple, infrequent bending, a manual bender might suffice. For more substantial, repeated bending of thicker pipes, a hydraulic bender could be more suitable. Electric benders are best for high precision and efficiency in large-scale projects. Consider your project's needs and budget when choosing.

Can I Bend All Types of Pipes with a Pipe Bender?

Not all pipes are suitable for bending, as the process depends on the material, thickness, and diameter of the pipe. Metal pipes like copper, aluminum, and thin-walled steel can often be bent successfully. However, thicker steel pipes may require a hydraulic or electric bender. PVC or other plastic pipes require different methods, typically involving heating. Always check the specifications of your pipe and the capabilities of your bender.

How Can I Prevent Pipes from Cracking or Wrinkling When Bending?

To prevent damage during bending, it's important to use the correct type of bender and techniques suited to your pipe's material and dimensions. For metal pipes, use a bender with the appropriate size bending die and follow the manufacturer's guidelines for angle and speed. Ensure the pipe is free from defects and evenly heated if necessary. For softer materials like copper, you might use a spring or sand to support the internal structure during bending.

What Maintenance Is Required for Pipe Benders?

Regular maintenance ensures the longevity and effectiveness of your pipe bender. This typically includes cleaning the machine after each use, checking for any signs of wear or damage, lubricating moving parts, and storing it in a dry, clean space. For hydraulic benders, monitor the hydraulic fluid level and check for leaks. Refer to your bender’s manual for specific maintenance recommendations and follow them diligently to keep your bender in optimal condition.