Everything You Need to Know About Saw Blades

Introduction

Saw blades are the unsung heroes of woodworking and construction projects, silently slicing through materials to bring your visions to life. Whether you're a seasoned professional or a DIY enthusiast, choosing the right saw blade can make all the difference in the quality and efficiency of your work. In this comprehensive guide, we'll explore the world of saw blades, covering everything from types and materials to maintenance tips and beyond.

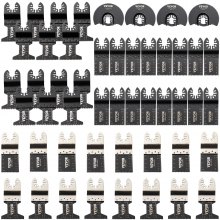

Types of Saw Blades

Circular Saw Blades

Circular saw blades are versatile tools commonly used in woodworking, carpentry, and construction. They feature toothed edges that rotate around a central hub, making quick and precise cuts through various materials such as wood, metal, and plastic.

Band saw blades consist of a continuous band of metal with teeth on one side, stretched between two or more wheels. This design allows for intricate curved cuts and is often favored for resawing lumber or cutting irregular shapes.

Jigsaw Blades

Jigsaw blades are narrow, toothed blades designed to fit into a jigsaw's reciprocating motion. They excel at cutting curves and intricate patterns in wood, metal, and other materials with ease.

Reciprocating Saw Blades

Reciprocating saw blades, also known as "recip saw" or "sawzall" blades, feature a straight, narrow design with teeth along one edge. These blades are ideal for demolition work, cutting through wood, metal, plastic, and even masonry.

Scroll Saw Blades

Scroll saw blades are thin, delicate blades designed for intricate, detailed cuts in thin materials like wood, plastic, and metal. They're commonly used by hobbyists and craftsmen for intricate woodworking projects.

Materials Used in Saw Blades

High-Speed Steel (HSS)

High-speed steel blades are known for their durability and ability to maintain a sharp edge even at high temperatures. They're suitable for cutting wood, metal, and plastic, making them a popular choice for general-purpose cutting tasks.

Carbide-Tipped Blades

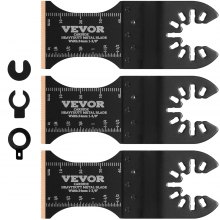

Carbide-tipped blades feature teeth made of carbide, a hard and durable material that provides excellent cutting performance and longevity. These blades are ideal for cutting hard materials like hardwood, laminate flooring, and metals.

Diamond Blades

Diamond blades utilize synthetic diamond crystals embedded in the blade's edge to cut through tough materials like concrete, tile, and stone with ease. They're commonly used in masonry and construction applications where precision and durability are essential.

Choosing the Right Saw Blade

Selecting the appropriate saw blade for your project is crucial for achieving optimal results. Consider the following factors when choosing a saw blade:

Material Compatibility

Ensure that the blade you choose is suitable for cutting the material you're working with. Different materials require different blade types and tooth configurations for optimal performance.

Tooth Configuration

The tooth configuration of a saw blade determines its cutting speed, finish quality, and chip removal. Choose a tooth pattern that's appropriate for the type of cuts you need to make, whether it's rip cuts, crosscuts, or fine finish cuts.

Blade Size

Select a blade size that matches your saw's specifications and the requirements of your project. Using the correct blade size ensures smooth operation and prevents damage to both the blade and the saw.

Maintenance and Care Tips

Proper maintenance and care can extend the life of your saw blades and ensure consistent cutting performance. Here are some tips to keep your blades in top condition:

Keep Blades Clean

Regularly remove built-up pitch, resin, and other debris from your saw blades to prevent blade dulling and overheating during use.

Sharpen Blades When Necessary

Monitor the sharpness of your saw blades and sharpen them as needed to maintain optimal cutting performance. Dull blades not only produce poor-quality cuts but also increase the risk of kickback and accidents.

Store Blades Properly

Store your saw blades in a dry, clean environment to prevent corrosion and damage. Use blade protectors or cases to avoid accidental contact and ensure safe handling.

Conclusion

Saw blades are essential tools for a wide range of cutting tasks, from simple woodworking projects to complex construction endeavors. By understanding the different types of saw blades, materials, and maintenance tips, you can confidently select the right blade for your needs and achieve professional-quality results every time. Don't let subpar blades hinder your creativity and productivity—invest in high-quality saw blades from VEVOR and unlock your full potential. Happy cutting!

FAQs about Saw Blades

What are the different types of saw blades available in the market?

There are various types of saw blades designed for specific purposes, such as rip-cutting, cross-cutting, and combination blades. Additionally, there are specialty blades like dado blades, scroll saw blades, and band saw blades. Each type is crafted with specific tooth configurations and materials to optimize performance for particular cutting tasks.

How do I choose the right saw blade for my project?

Selecting the appropriate saw blade depends on several factors, including the type of saw you're using, the material you're cutting, and the desired cut quality. For example, if you're cutting hardwood, a blade with more teeth and a finer tooth configuration would provide smoother cuts. On the other hand, for rough carpentry tasks, a blade with fewer teeth and a more aggressive tooth design might be more suitable.

How do I maintain and prolong the lifespan of my saw blades?

Proper maintenance is crucial for extending the lifespan of your saw blades. Regular cleaning to remove resin buildup and debris helps prevent corrosion and maintains cutting efficiency. Additionally, ensuring the blade is properly tensioned and aligned reduces wear and tear. Remember to sharpen or replace dull blades promptly to maintain cutting precision and prevent damage to your materials and equipment.

Can I use any saw blade with my saw, or are there compatibility issues?

While many saw blades are designed to fit standard saws, it's essential to check compatibility before use. Different saws may require specific blade sizes, arbor hole diameters, and mounting configurations. Using an incompatible blade can lead to poor performance, safety hazards, and potential damage to your saw. Always refer to your saw's user manual or consult with a professional to ensure you're using the right blade for your equipment.

How can I ensure safety when using saw blades?

Safety should always be a top priority when working with saw blades. Ensure that your saw is properly set up and secured, with all safety guards and devices in place. Wear appropriate personal protective equipment, such as safety goggles and hearing protection. Always follow proper cutting techniques and avoid cutting materials that are excessively hard, thick, or prone to binding. Regularly inspect your equipment for any signs of wear or damage and replace worn-out parts promptly. Lastly, read and follow all safety guidelines provided by the manufacturer.