Master the Art of Tubing Benders: A Comprehensive Guide

Understanding Tubing Benders

Exploring the Versatility of Tubing Benders

Tubing benders are versatile tools that play a crucial role in various industries, from automotive to plumbing and beyond. These tools are designed to bend metal tubes and pipes with precision, allowing users to create complex shapes and configurations effortlessly. Whether you're a professional tradesperson or a DIY enthusiast, understanding the capabilities of tubing benders can unlock a world of possibilities.

Types of Tubing Benders

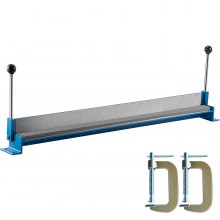

There are several types of tubing benders available on the market, each with its unique features and advantages. Manual tubing benders are ideal for small-scale projects and offer greater control over the bending process. Hydraulic tubing benders, on the other hand, are suitable for heavy-duty applications and can bend thicker tubes with ease. Additionally, there are electric and pneumatic tubing benders that provide increased efficiency and productivity.

Choosing the Right Tubing Bender

Factors to Consider When Selecting a Tubing Bender

When choosing a tubing bender, it's essential to consider various factors to ensure that you select the right tool for your specific needs. Factors such as the material, size, and thickness of the tubes you'll be bending, as well as the level of precision required, will influence your decision. Additionally, considering factors such as portability, ease of use, and durability can help you make an informed choice.

Key Features to Look for in Tubing Benders

Modern tubing benders come with a range of features designed to enhance performance and user experience. Look for features such as multiple bending dies for different tube sizes, adjustable bend angles for greater flexibility, and built-in mandrels for maintaining the integrity of the tube during bending. Other features to consider include quick-change tooling systems, digital readouts for precise measurements, and ergonomic designs for comfort during extended use.

Tips for Using Tubing Benders Effectively

Proper Techniques for Bending Tubes

To achieve optimal results when using a tubing bender, it's essential to employ proper techniques. Start by securing the tube firmly in the bender and selecting the appropriate bending die for the desired bend radius. Gradually apply pressure to the tube while supporting it to prevent distortion or kinking. Avoid overbending the tube, as this can lead to structural weaknesses and compromise the integrity of the bend.

Maintaining Safety When Using Tubing Benders

Safety should always be a top priority when working with tubing benders. Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect yourself from flying debris and sharp edges. Always follow the manufacturer's instructions and guidelines for safe operation, and never exceed the maximum bending capacity of the bender. Inspect the bender regularly for any signs of wear or damage, and replace worn or damaged parts promptly to prevent accidents.

Exploring Applications of Tubing Benders

Automotive Industry

In the automotive industry, tubing benders are used for fabricating custom exhaust systems, roll cages, and chassis components. Whether you're building a race car or customizing a classic vehicle, a tubing bender is an essential tool for achieving professional-quality results.

Plumbing and HVAC

In the plumbing and HVAC industries, tubing benders are used for bending copper and stainless steel pipes to precise angles for installation. Whether you're installing a new plumbing system or repairing existing pipes, a tubing bender can help you get the job done quickly and efficiently.

Conclusion: Elevate Your Craft with Tubing Benders

Investing in a high-quality tubing bender is a wise decision for any tradesperson or DIY enthusiast. With the right tool at your disposal, you can tackle a wide range of projects with confidence and precision. Whether you're working in the automotive, plumbing, or HVAC industry, mastering the art of tubing bending will elevate your craft to new heights. Take the first step towards excellence today with VEVOR, your trusted partner in quality tools and equipment.

FAQs about Tubing Benders

What are tubing benders used for?

Tubing benders are primarily used for shaping metal tubing or pipes without crimping or collapsing them. They are commonly employed in various industries such as plumbing, automotive, HVAC (Heating, Ventilation, and Air Conditioning), and manufacturing. With tubing benders, you can create precise bends in tubing to fit specific design requirements, making them indispensable tools in many fabrication and construction projects.

What types of tubing benders are available?

There are several types of tubing benders catering to different needs and preferences. The main categories include manual tubing benders, hydraulic tubing benders, and electric tubing benders. Manual tubing benders are operated by hand and are suitable for smaller-scale projects or occasional use. Hydraulic tubing benders utilize hydraulic pressure to bend tubing efficiently, making them ideal for heavy-duty applications. Electric tubing benders are powered by electricity and offer automated bending processes, often preferred for high-volume or repetitive tasks.

How do I choose the right tubing bender for my project?

Choosing the right tubing bender depends on various factors such as the material, thickness, and diameter of the tubing, as well as the complexity and volume of the bends required for your project. Consider the type of material you'll be working with (e.g., steel, aluminum, copper), the size of the tubing, and the frequency of use. Additionally, factor in your budget and workspace constraints. It's advisable to consult with experts or refer to manufacturer guidelines to ensure you select the most suitable tubing bender for your specific needs.

Can tubing benders bend different types of materials?

Yes, tubing benders are versatile tools capable of bending various types of materials, including steel, stainless steel, aluminum, copper, and brass. However, it's essential to choose a tubing bender compatible with the specific material you intend to work with, as different materials may require different bending techniques and tooling. Some tubing benders may come with interchangeable dies or accessories to accommodate different materials, offering flexibility and versatility in bending operations.

How do I use a tubing bender safely?

Safety is paramount when operating tubing benders to avoid accidents or injuries. Always read and follow the manufacturer's instructions and safety guidelines carefully. Wear appropriate personal protective equipment (PPE) such as gloves and safety glasses to protect yourself from potential hazards. Ensure the tubing bender is securely mounted or stabilized before use to prevent it from tipping over or moving unexpectedly. Take your time to set up the bending parameters correctly and double-check them before initiating the bending process. Regularly inspect the tubing bender for any signs of wear or damage, and maintain it according to the manufacturer's recommendations to ensure safe and efficient operation over time.