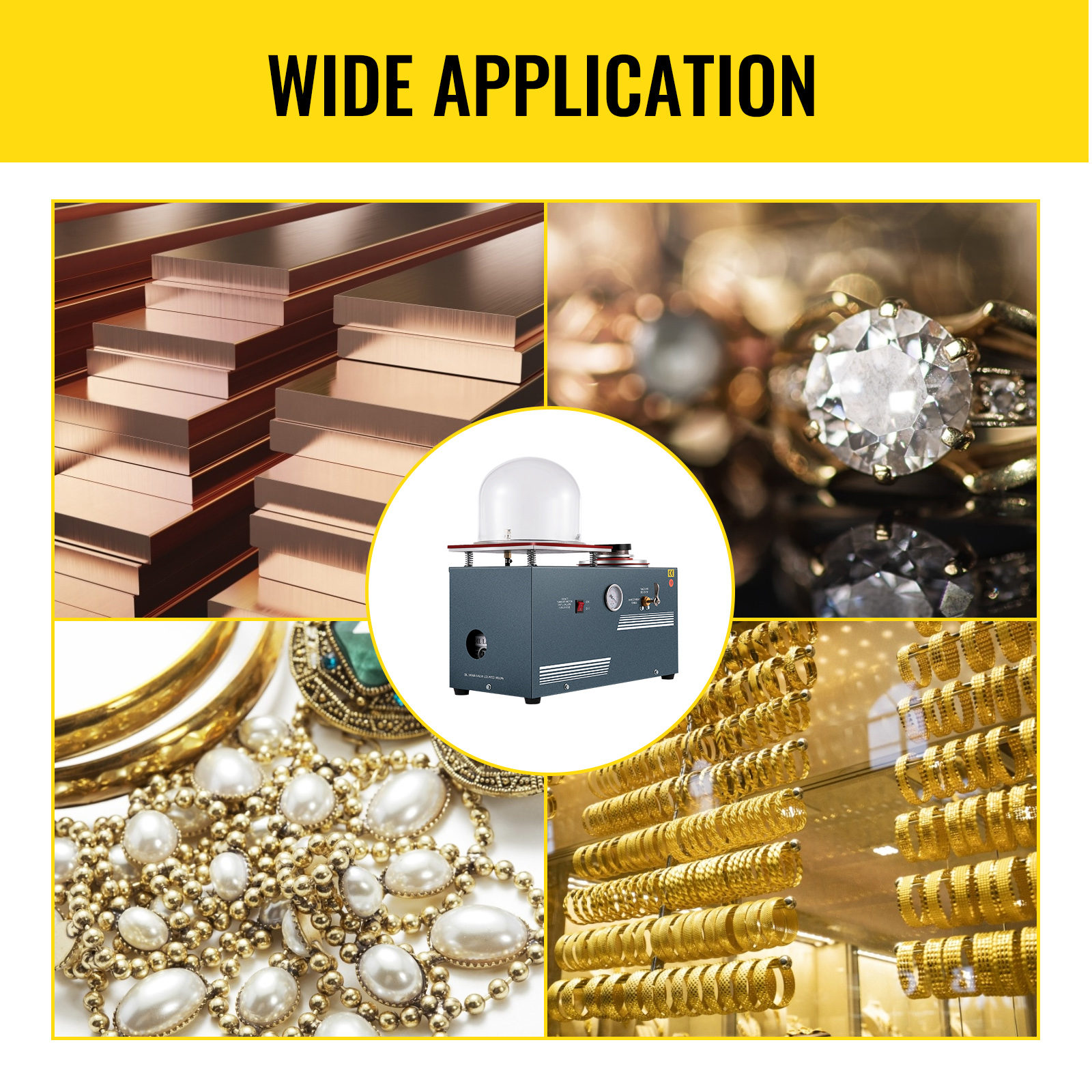

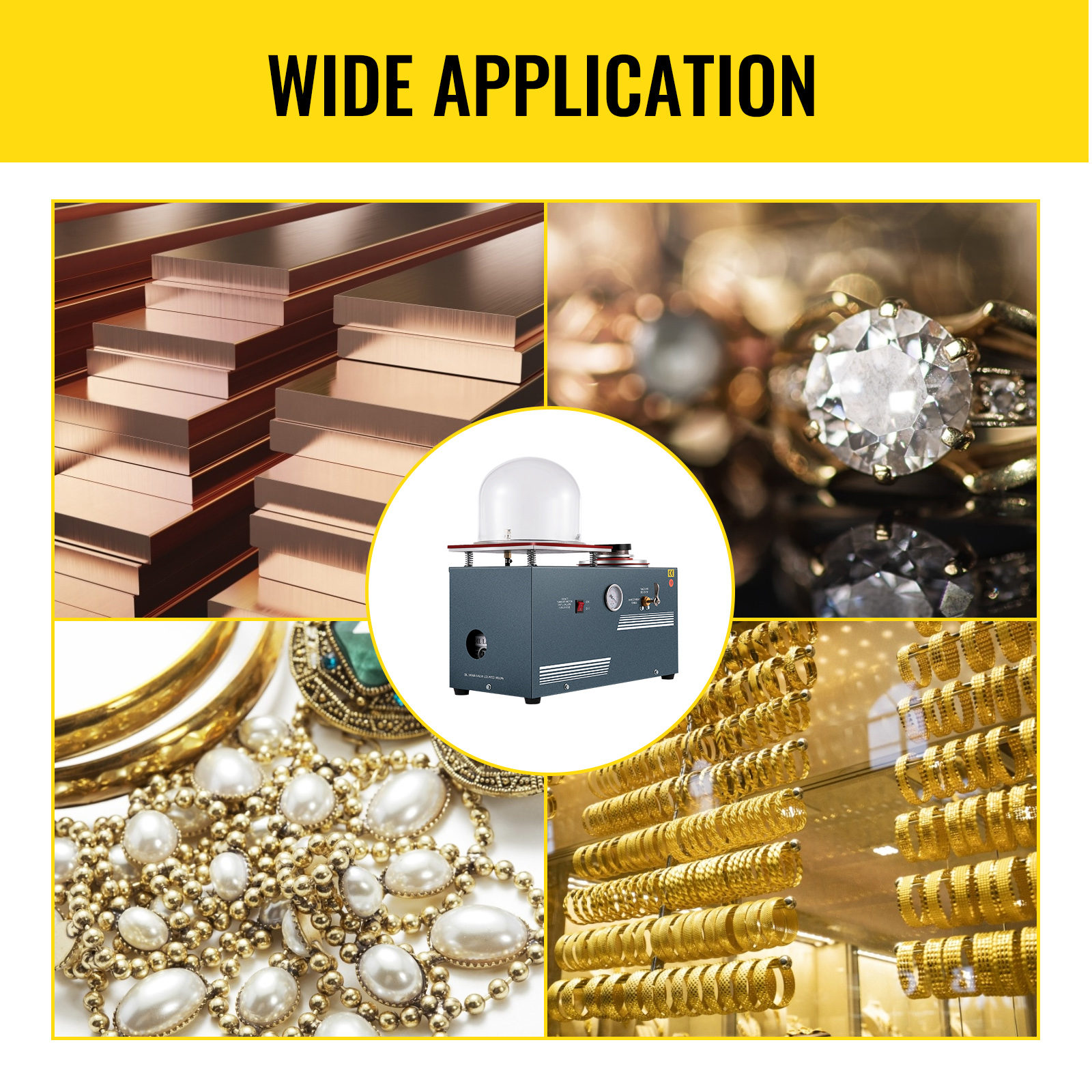

Say goodbye to air pockets and uneven surfaces with the VEVOR casting equipment. This 3 CFM pump casting machine features a power source that provides a clean and flawless finish on all invested flasks and molds. This machine also features robust and long-lasting components that enhance its durability. Jewelers and hobbyists alike rave about the consistently smooth and professional results this machine produces. Whether you are casting complex jewelry or making delicate RTV molds, this VEVOR machine guarantees high-quality results every time.

Not only does this casting equipment have a durable material, but it also features a user-friendly design, thus providing a hassle-free operational experience. It has a comfortable handle and soft rubber feet that keep the machine stable. Every detail in its design makes the operation easier and the experience smoother. With a built-in lubrication system, this machine allows easy adjustments and ensures that the users benefit from its enhanced performance while putting in minimum effort.

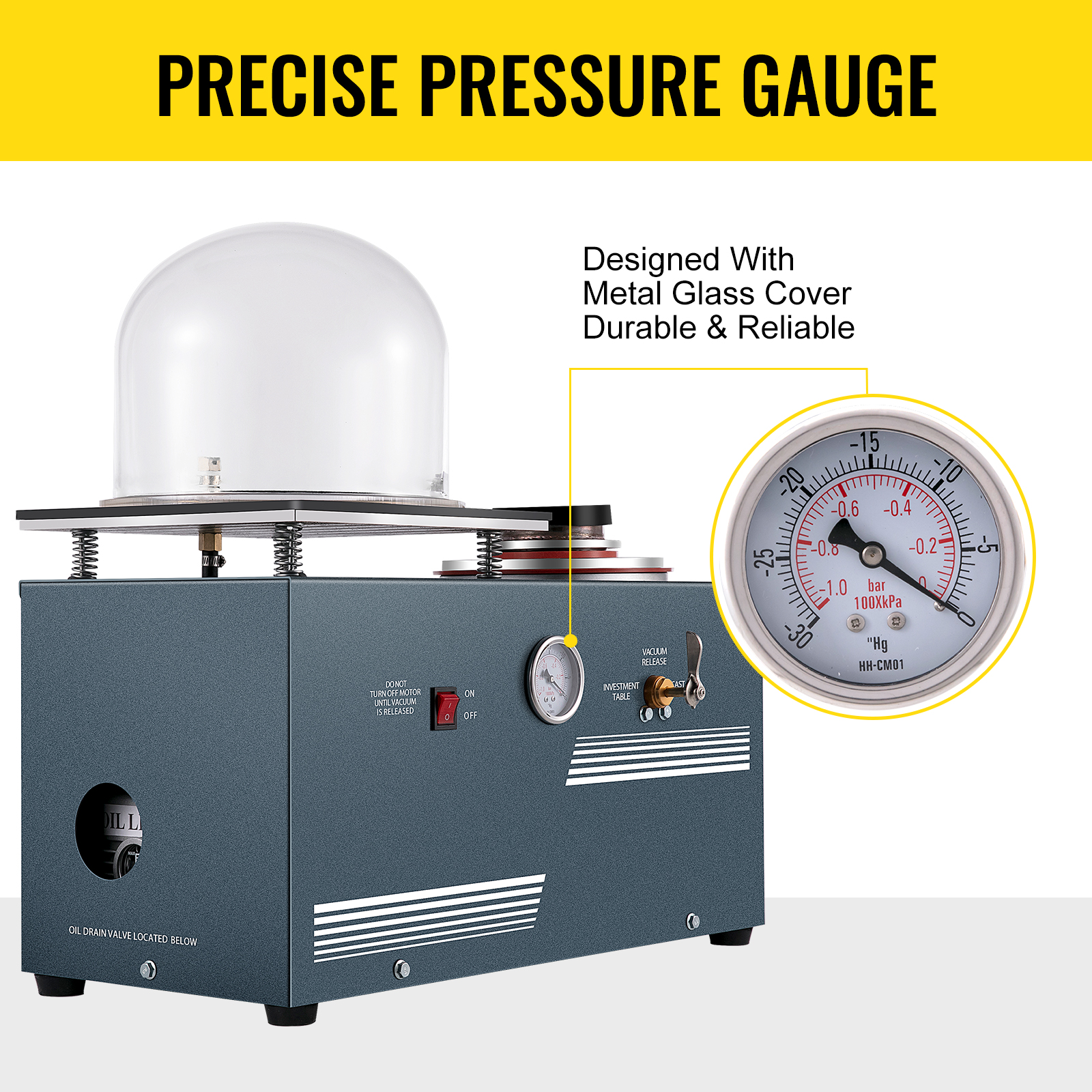

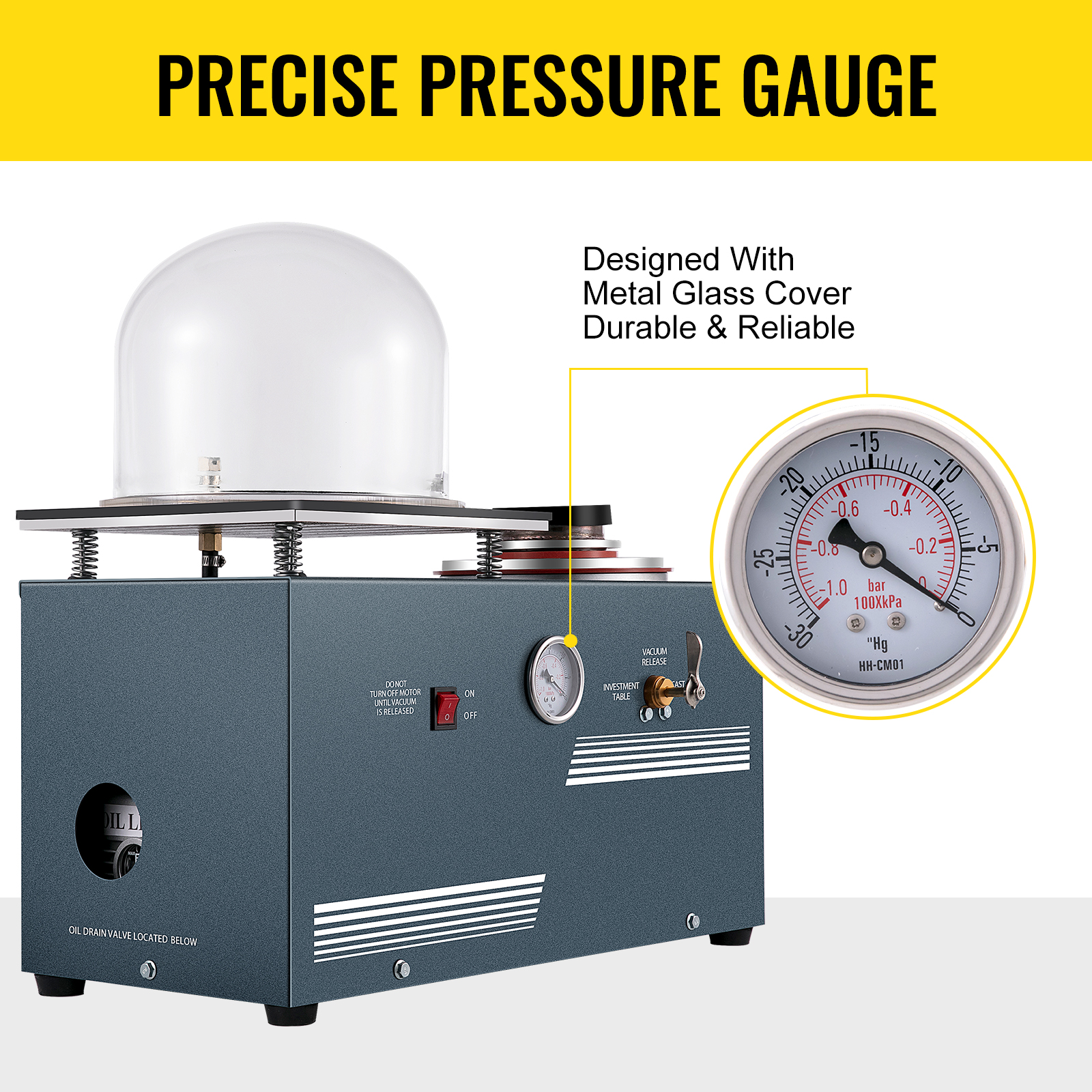

The VEVOR 2L casting machine provides great accuracy and precision. This machine has a precision pressure gauge that allows the user to monitor and adjust the current pressure. This enhanced feature gives perfect accuracy every time the user swings it. With a controlled environment and precise material flow, this machine produces fine castings with minimal defects. This reliability enhances its efficiency and meets strict industry standards.

With enhanced scalability, this vacuum-casting machine allows users to maintain their product volumes more efficiently. From low-volume prototypes to large-scale production, this vacuum casting machine adapts without compromising the quality of results. Its flexibility makes it an ideal machine for industries with fluctuating demands of increasing capacity during high-demand periods. The scalability of this machine enables companies to respond well to market demands while utilizing resources and scheduling production.

With an advanced system, this invested flask-casting machine features real-time sensors and artificial intelligence algorithms. These enhanced features dynamically monitor and adjust the flow of casting materials. With continuous optimization of material distribution based on mold geometry, this machine ensures uniform filling. It reduces the likelihood of bubbles and defects. This advanced adaptive feature makes it easy for users and industrialists to manage their casting flow materials more efficiently.

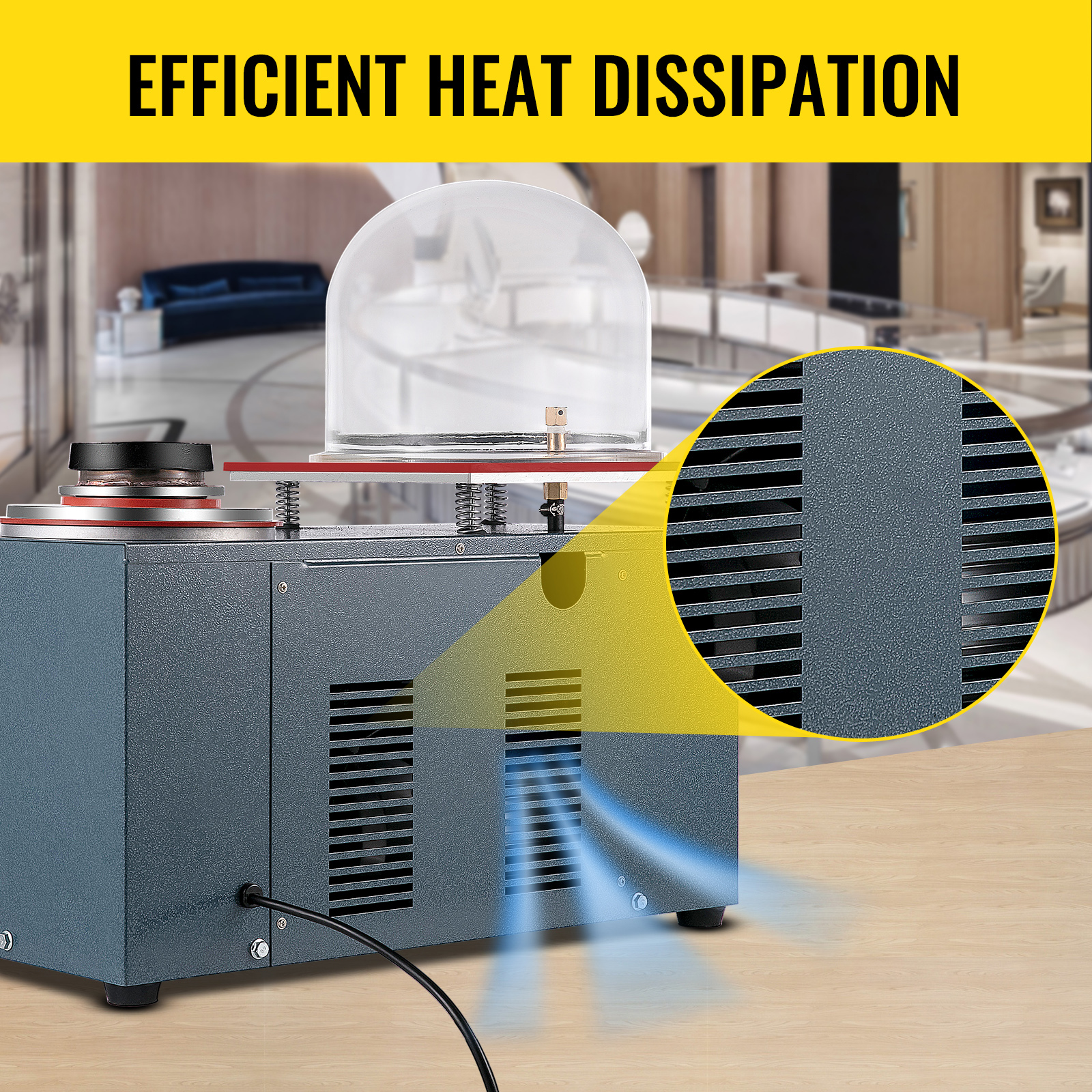

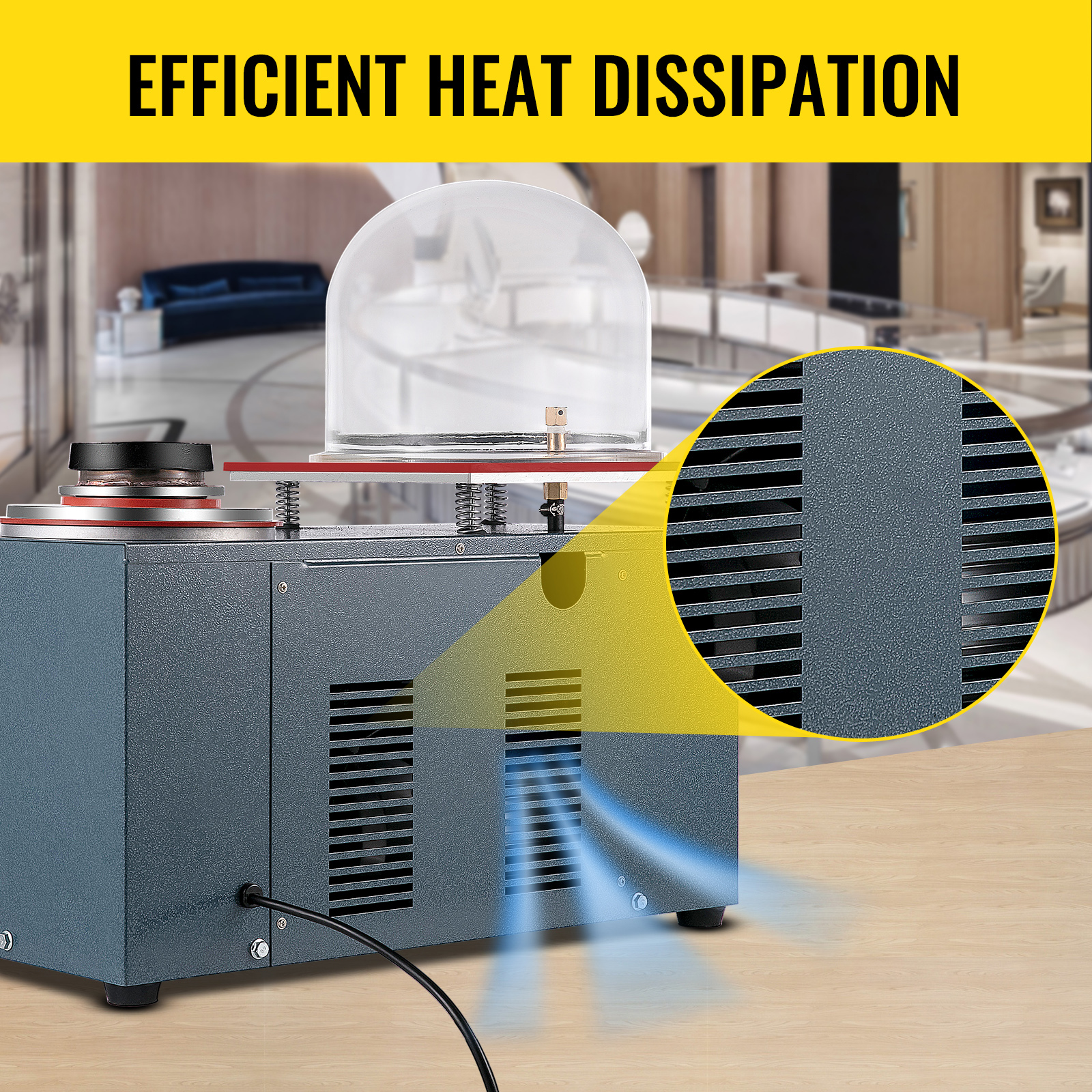

The VEVOR vacuum casting machine features a solid metal body, along with high-quality stainless-steel components. These features enable this machine to withstand frequent use rigors. It offers long-lasting performance, even after repeated use. Its sturdy construction enables this machine to withstand heating and reheating. Its tough stainless-steel design enables this RTV mold-casting machine to withstand all the wear and tear efficiently without compromising on the quality.

With a controlled environment, this machine reduces material losses and ensures the best use of the available resources. Unlike traditional casting models, this industrial vacuum casting machine reduces emissions and material losses and ensures the best use of resources. It can recycle and reuse material during the casting process, thus further reducing negative impacts on the environment. Its sustainability meets the goals of the global environment and helps users reduce costs associated with waste disposal and energy use.

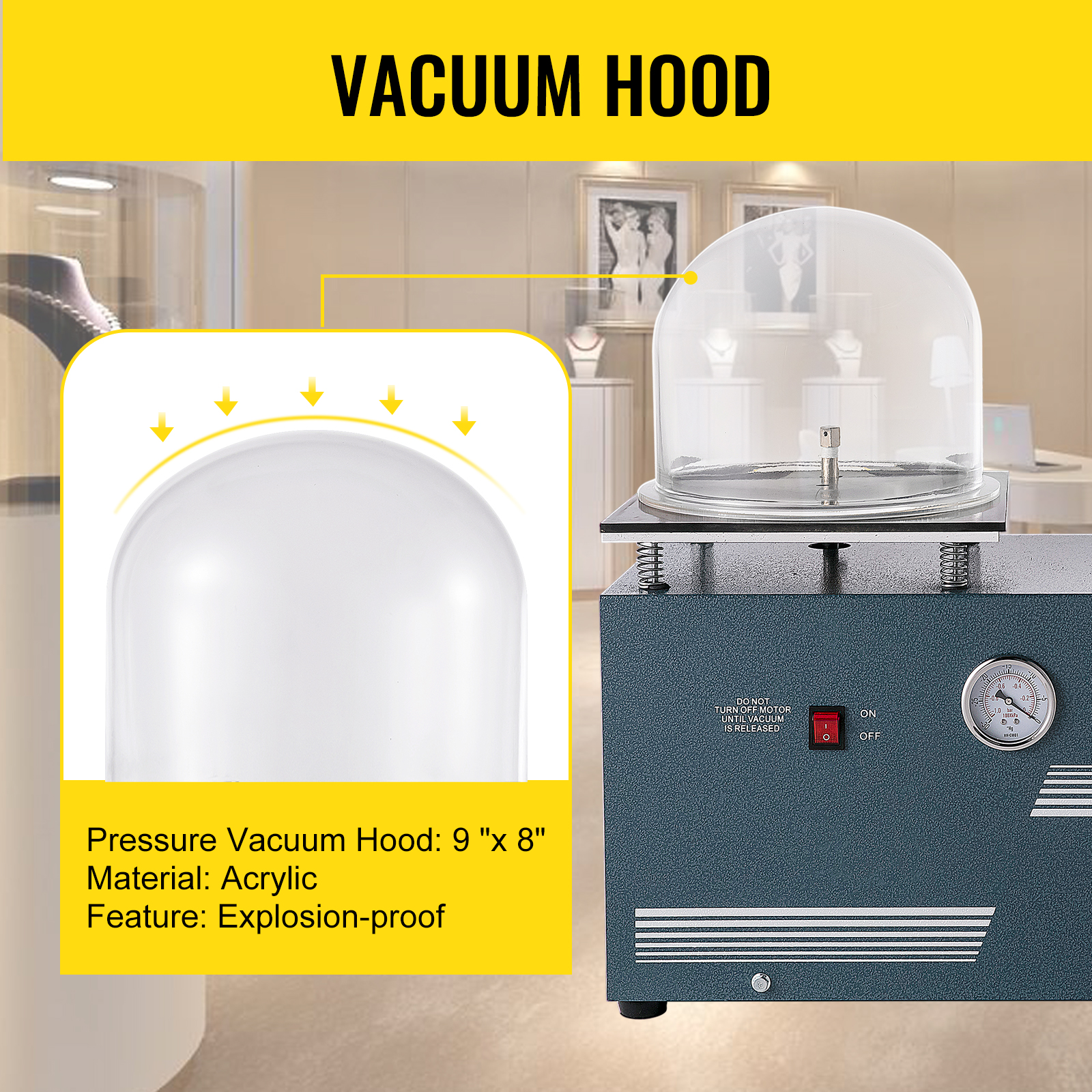

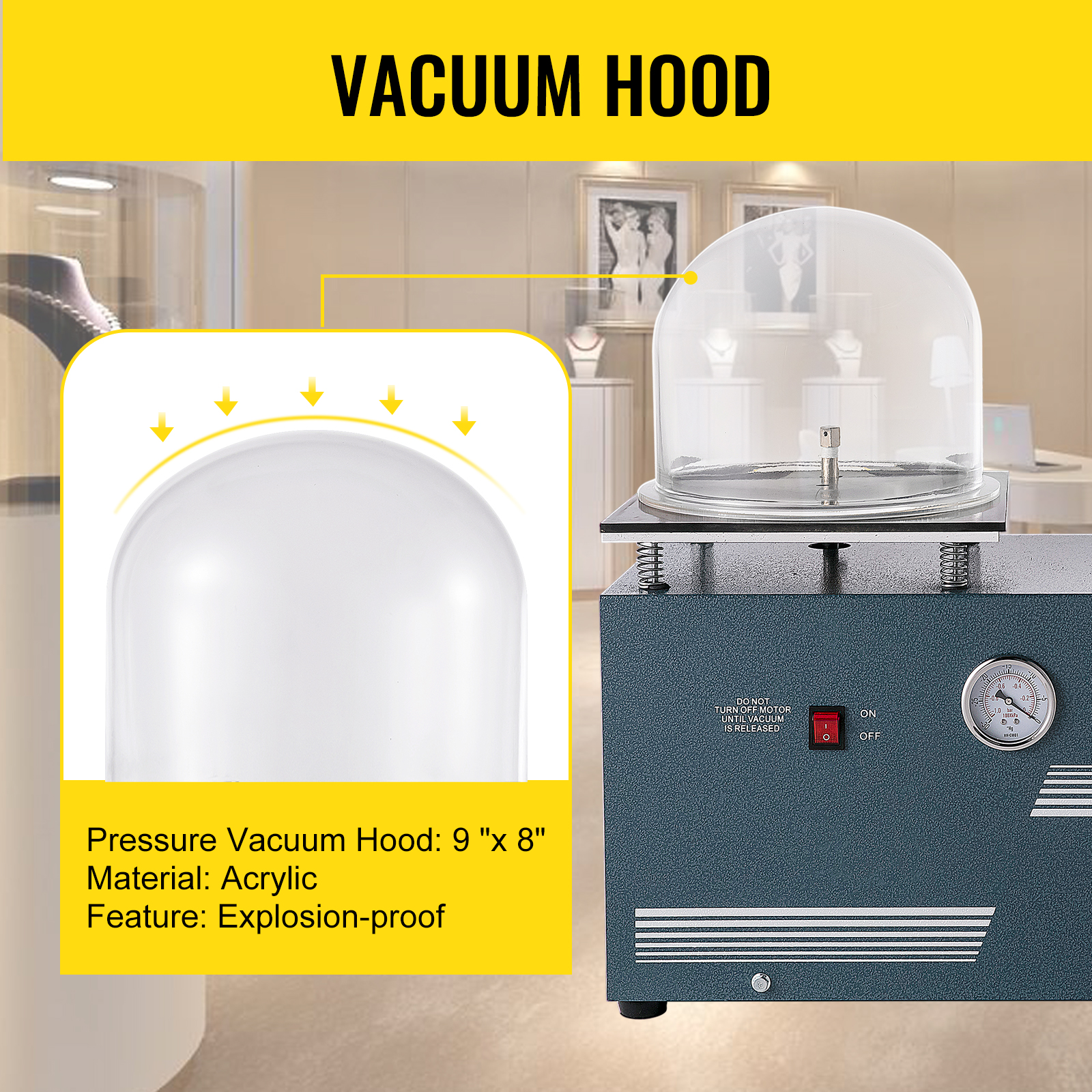

Not only is this a jewelry-casting machine, but it is also a perfect tool for crafting intricate molds. This machine features a vacuum cap that is made of thick, aerospace-grade plastic material. This material helps reduce blurs and bubbles and ensures that every product produced by this industrial vacuum casting machine meets the highest quality standards. This machine is ideal for a variety of applications, ranging from jewelry processing to high-density art pieces.